New Model FDY optical white polyester yarn with best service

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic info

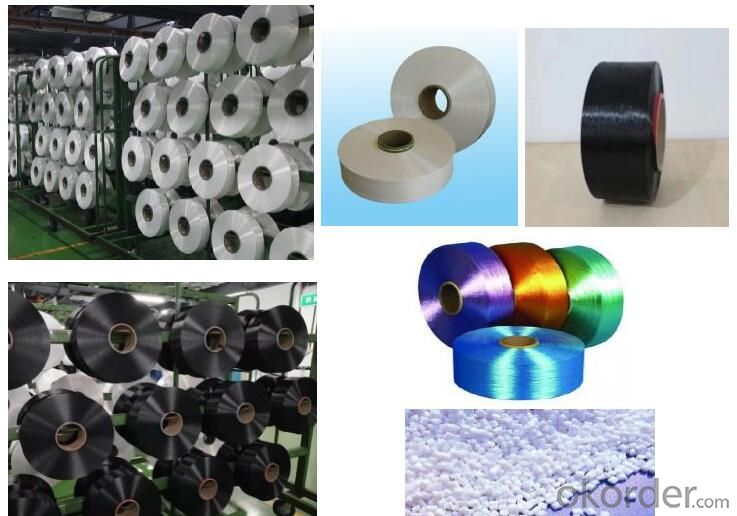

Product name: FDY 1000D HIGH TENACITY INDUSTRIAL YARN

Material: 100% Polyester

Pattern: dope-dyeing

Yarn Type: FDY, Filament

Feature: Eco-Friendly, Recycled, High Tenacity

Use: Weaving, Knitting, Sewing , Weaving , Knitting

Twist: S/Z TWIST

Evenness: EVEN

Color: white , black

MOQ: 30 KGS

Quality: AA Grade

Package: Pallet

Package Type: 4bobbins/carton, 10KG/bobbin, 40KG/cartons, 12 tons/20gp, 24 tons/40HQ

Certification: GRS, TC, OEKO

Keywords: Recycled FDY yarn, R-pet yarn, Eco-Friendly yarn

Specification: 50D/24F~144F, 75D/36F~144F, 100D/36F~288F, 150D/36F~288F, 200D/72F~288F, 300D/72F~576F, 450D/144F, 450D/192F, 600D/144F, 600D/192F or as per customers customized, single or double

Application: THE APPLICATION OF HIGH TENACTIY YARN IS FOR SLING, CONVEYOR BELT, GEOGRID, GEOTEXTILE, YARN-COATING, ROPE, SEWING THREAD, WEBBING, TIE DOWN, NETTING, HOSES, TEXTILENE, ETC.

Payment: T/T, LC

Supply Ability: 4000 Metric Ton/Metric Tons per Month

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

- Q: What is the cheese yarn?

- Knitting factory and other yarn factory also has some customers to buy hank yarn and then into the cheese yarn. Or yarn finished yarn and then anti-playing into the cheese yarn, so the cheese yarn with the white yarn and yarn, cheese yarn ingredients can also be cotton, wool, silk, linen, chemical fiber and other raw materials, as shown.

- Q: In the textile fabric, mesh cloth and the difference between the Bali yarn is what

- Have good ventilation and moderate ability to adjust. Compared with other banner fabric, mesh cloth permeability better, in the outdoor life cycle will be longer.

- Q: What is the meaning of the yarn?

- To make a hair is to dye the yarn through the machine into a cheese, shaking the yarn or cheese yarn re-coiled into the specified weight of the yarn process.

- Q: What is the process of towel in the textile?

- Electronic jacquard machine without the need to design a good program, including the flower and auxiliary needle control, dobby machine to design the program, if it is the most original machine to design a spike and shuttle steel plate, Organize the design of the pattern of the organization.

- Q: Cotton yarn from the process and use is how to divide

- ) Combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → yarn → down tube (sub-manned winding and automatic winding two) → finished product inspection

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- The more the better the quality, the finer the yarn, the thinner the yarn weave, the more soft and comfortable the cloth is. The number of branches is fixed, so the greater the number of yarns, the finer the yarn. British count is not China's current legal indicators of yarn fineness, but still widely used in the enterprise, especially the cotton textile industry.

- Q: Textile spinning workshop car car summary and plan

- Summary, is a time period of the situation to conduct a comprehensive and systematic overall evaluation, total analysis, analysis of results, lack of experience and so on. Summary is the application of a writing, is done on the rational thinking of the work done

- Q: What is the diameter of a yarn of 40 yarns?

- The diameter of the yarn is related to the number of yarns (the number of cables in the linear density), the raw material and the twist. Commonly used approximation method to calculate the yarn diameter: cotton yarn diameter can be calculated using the following two methods:

- Q: From the yarn to the finished textile fabric production process

- Nylon modified varieties such as nylon, single-cast nylon (MC nylon), reactive injection molding (RIM) nylon, aromatic nylon, transparent nylon, high impact (super tough) nylon, electroplated nylon, conductive nylon , Flame retardant nylon, nylon and other polymer blends and alloys, to meet the different special requirements, widely used as metal, wood and other traditional materials substitutes, as a variety of structural materials.

- Q: How to reduce the cost of textile yarn dyeing

- 1, now due to the domestic environmental situation is grim, the dye may be a temporary small increase in prices, there will not be a substantial price increases, but also not save 2, labor: labor wages are now rising, the insurance state to pay, Can not save

Send your message to us

New Model FDY optical white polyester yarn with best service

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches