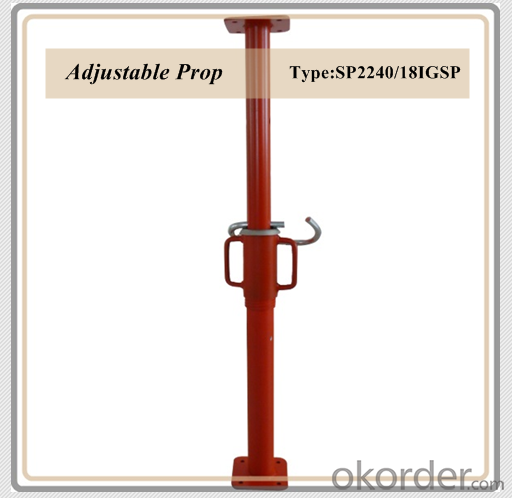

Export Adjustable Props /painted surface steel prop / telescopic steel prop / red color prop 2.2-4M

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1680 Piece/Pieces pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

1. Length 2200-4000mm

2. Outer tube diameter 56mm

3. Inner tube diameter 48mm

4. Tube material : Q235

5. Tube thickness : 1.8mm

6. weight : 10kgs

7. square plate : 120*120*4mm

8. Italian type nut

9. G-pin 12

10. Painted surface

11. Color : as customer 's request . red / blue / green / orange/ brown

Packaging & Delivery

| Packaging Details: | packaging :50pcs / bale container : 1680pcs / 20ft |

|---|---|

| Delivery Detail: | 20-30days after receive deposit |

Specifications

Adjustable props / construction prop

Height 2.2-4M

Italy type painted props

Adjustable props

Shoring props

Construction scaffold steel prop

Scaffold props

Telescopic steel props

Product introduce

Steel Prop is a labour and time saving device to support shuttering and centering.

It is made outer tube of 60mm (O. D.) & inner pipe of 48mm (O. D.)

or outer tube 56mm (O.D.) & inner pipe 48mm (O.D.) ,

or outer tube 48mm (O.D.) & inner pipe 40 mm (O.D.) moving in each other telescopically.

The surface has painted , powder , electric galvanized and hot dipped galvanized .

The height use of props by double staging is recommended upto 7000mm only .

Top and bottom plate are provided with nail holes for wooden beam or steel beam .

The top has square shape , flower shape or U-head , U-fork head .

U-head can use fix or adjustable .

- Q: Can steel props be used for temporary support in offshore platforms?

- Yes, steel props can be used for temporary support in offshore platforms. Steel props are commonly used in construction to provide temporary support to structures or platforms during their construction or maintenance phases. They offer high load-bearing capacity and can withstand the harsh offshore environment, making them suitable for temporary support in offshore platforms.

- Q: How do you dismantle a steel prop safely?

- To safely dismantle a steel prop, follow these steps: 1. Ensure proper safety precautions: Before starting the dismantling process, put on the necessary personal protective equipment (PPE) such as safety goggles, gloves, and a hard hat. Make sure you have a clear work area and have identified any potential hazards. 2. Assess the prop: Examine the steel prop to understand its structure and components. Identify any locking mechanisms, pins, or bolts that need to be removed. 3. Release the load: If the steel prop is supporting any weight, carefully release the load by slowly lowering it onto a stable surface. This will ensure the prop is not under any strain during dismantling. 4. Remove any locking mechanisms: Steel props often have locking mechanisms that secure their components together. Locate and remove any locking pins, bolts, or nuts using the appropriate tools, such as wrenches or spanners. 5. Disassemble the prop: Once all locking mechanisms are removed, begin disassembling the prop by separating its components. Start from the top and work your way down, carefully unscrewing or unbolting each section. 6. Follow the manufacturer's instructions: Some steel props may have specific instructions or guidelines provided by the manufacturer for safe dismantling. If available, consult these instructions to ensure you are following the recommended dismantling procedure. 7. Use mechanical aids if necessary: Depending on the size and weight of the steel prop, you may need to use mechanical aids such as cranes, hoists, or lifting equipment to safely handle and move the components during dismantling. 8. Store or dispose of the components: Once the steel prop is fully dismantled, organize the components in a safe and organized manner. Store them appropriately for future use or dispose of them based on local regulations and guidelines. Remember, safety should always be the top priority when dismantling any structure or equipment. If you are uncertain about any step or lack the necessary experience, consult a professional or seek guidance from an expert in the field.

- Q: Are steel props adjustable with pneumatic mechanisms?

- No, steel props are not adjustable with pneumatic mechanisms. Steel props, also known as steel shore or steel acrow prop, are typically used in construction to support and provide temporary stability to structures during renovation or repair work. These props are made of steel tubes with adjustable lengths, allowing them to be extended or shortened as needed. However, the adjustment is done manually by turning a threaded collar to increase or decrease the length of the prop. Pneumatic mechanisms, on the other hand, rely on compressed air to operate and are commonly used in various applications such as tools, machinery, and automation. While pneumatic mechanisms can provide adjustable and precise control, they are not typically used in steel props as these props are designed to be adjusted manually by the user.

- Q: Can steel props be used for temporary support during HVAC system installation?

- Yes, steel props can be used for temporary support during HVAC system installation. Steel props are adjustable and provide sturdy support, making them suitable for holding up heavy equipment like HVAC systems during installation.

- Q: What are the different load classes available for steel props?

- The load classes for steel props available are dependent on the project's specific requirements and specifications. However, four main load classes are commonly utilized for steel props: 1. Light Duty Load Class: This load class is suitable when there is a minimal load requirement. It typically supports small structures temporarily, like formwork, falsework, or scaffolding. 2. Medium Duty Load Class: Projects requiring a moderate load-bearing capacity benefit from this load class. It is commonly used to support larger structures, such as beams or slabs, during construction or renovation work. 3. Heavy Duty Load Class: Designed to handle substantial loads, this load class is commonly used where a high load-bearing capacity is necessary. It supports heavy structures like multi-story buildings or bridges. 4. Extra Heavy Duty Load Class: This load class is specifically for projects that demand an extremely high load-bearing capacity. It is commonly used to support exceptionally heavy structures, like industrial equipment or machinery. It is worth noting that the load capacity of steel props can vary depending on the design, size, and material grade of the prop. Therefore, consulting with structural engineers or industry professionals is crucial to determine the appropriate load class for a specific project, ensuring safety and structural integrity.

- Q: Steel braced steel purlin and anchor beam waist connection

- Depending on the distance between the main direction of the water should be fixed, the mainstream water should be encrypted when large. The anchor cable is connected with the joint plate with holes.

- Q: How do you ensure the stability of a steel prop in high winds?

- To ensure the stability of a steel prop in high winds, several measures can be taken. Firstly, the prop should be securely anchored to the ground using appropriate foundation systems, such as concrete footings or ground screws, to provide a strong and stable base. Additionally, the prop should be designed with sufficient structural strength and rigidity to withstand the forces exerted by high winds. This can be achieved by using thicker steel sections, reinforced bracing, or additional supports if necessary. Regular inspections and maintenance are also crucial to identify any signs of damage or wear that could compromise the stability of the prop, allowing for timely repairs or replacements as needed.

- Q: Can steel props be used for supporting temporary amusement park rides or attractions?

- Yes, steel props can be used for supporting temporary amusement park rides or attractions. Steel is a strong and durable material that can provide the necessary stability and structural support required for such installations.

- Q: Can steel props be used in construction of water tanks?

- Yes, steel props can be used in the construction of water tanks. Steel props are adjustable and reliable supports that can be used to provide temporary or permanent structural stability during the construction process. They are commonly used in various construction projects, including the construction of water tanks. Steel props are known for their strength and load-bearing capacity, which makes them suitable for supporting the weight of the tank walls and roof. Additionally, steel props can be easily adjusted to different heights, allowing for flexibility in the construction process. Therefore, steel props are a viable option for providing support during the construction of water tanks.

- Q: Can steel props be used for supporting temporary religious structures?

- Support for temporary religious structures can be provided by steel props. These props, also referred to as adjustable steel props or acrow props, are commonly utilized in the construction industry and temporary structures to ensure stability and support. They possess a flexible nature, allowing for easy adjustment to the desired height, which makes them suitable for various types of temporary structures, including those of a religious nature. Steel props are characterized by their strength and durability, enabling them to withstand substantial loads and provide structural support. With a wide base and adjustable top plate, they can be securely fixed to the ground, ensuring stability for the structures they uphold. This quality makes them particularly ideal for temporary religious structures like tents or temporary chapels, as they need to be strong and stable to guarantee the safety of worshippers. Furthermore, the installation and removal of steel props are straightforward, making them a practical choice for temporary structures that require quick assembly and disassembly. These props can be utilized to provide support for the roof or walls of the structure, ensuring both stability and integrity. In conclusion, steel props are a dependable and adaptable option for supporting temporary religious structures. They offer strength, stability, and ease of installation, making them a practical solution for maintaining the safety and stability of such structures.

Send your message to us

Export Adjustable Props /painted surface steel prop / telescopic steel prop / red color prop 2.2-4M

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1680 Piece/Pieces pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords