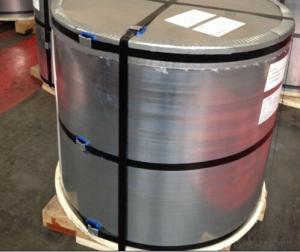

ETP thickness from 0.30 to 0.35

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main producers in Chinafor tinplate. At present, ourproductivity is about 450000 MT/year. Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, cleanenvironment to harvest the trust of the community, safety and health toconvince employees and energy-saving to be trusted by public". We areenjoying the trust and good name regarding to the superior quality and preferservice among the customers. Our products are sold nearly 150 enterprisesincluding Europe, America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

We has a customer service center whichproviding customers with whole-process service including the pre-sale, sale andafter-service, unified handling customer inquiries and complaints. CustomerService Center adhere to the goal “customer first and response rapidly” andarrange their service work according to the standard procedures. Ourcommitment: ready to accept advice and customer complaints, reply commentswithin 24 hours of treatment, when dealing with customer complaints of qualityissues, upon customer’s request, sent the inspector to the user site to saveproblem within 24 hours (within the province) and 48 hours (other provinces).

- Q: What are the main applications of tinplate?

- Tinplate is mainly used in the packaging industry for making cans, containers, and other metal packaging products. It provides excellent protection against corrosion, making it suitable for storing and preserving food, beverages, chemicals, and other perishable goods. Additionally, tinplate is also used in the manufacturing of aerosol cans, decorative items, and various other household products.

- Q: How does tinplate contribute to the reduction of food waste?

- Tinplate contributes to the reduction of food waste by providing a highly protective and durable packaging material for various food products. Its corrosion-resistant properties and ability to maintain food freshness for extended periods help to prevent spoilage and extend shelf life. Additionally, tinplate's ability to be easily recycled promotes sustainable packaging practices, reducing environmental impact and further supporting efforts to minimize food waste.

- Q: Can tinplate be used for aerospace applications?

- Yes, tinplate can be used for certain aerospace applications. It is commonly used for manufacturing small parts and components such as fasteners, connectors, and electrical contacts. However, it is not suitable for high-stress or extreme temperature conditions that are often encountered in aerospace applications. In such cases, more specialized and durable materials like titanium or stainless steel are preferred.

- Q: What are the different types of tinplate edge finishes?

- There are three main types of tinplate edge finishes: single edge, double edge, and scroll edge.

- Q: Can tinplate packaging be used for kitchen utensils?

- Yes, tinplate packaging can be used for kitchen utensils. Tinplate is a durable material that is resistant to corrosion and has good thermal conductivity, making it suitable for various kitchen utensils such as cans, containers, and even cookware.

- Q: What are the advantages of using tinplate for automotive parts?

- Tinplate offers several advantages for automotive parts. Firstly, it provides excellent corrosion resistance, making it ideal for parts exposed to harsh environmental conditions. Additionally, tinplate offers good formability, allowing for complex shapes and designs, providing flexibility in manufacturing. It also offers high strength and durability, ensuring long-lasting performance and safety. Furthermore, tinplate is lightweight, contributing to improved fuel efficiency and reduced emissions. Lastly, it is a cost-effective material, providing value for money in automotive part production.

- Q: Tin can weldingHow can the side of the column of the pop top be welded or pressed?,

- Mainly divided into the tank, the tank cover and the tank bottom three parts. The tank body is made of a piece of iron material through the curl bending machine, by using copper welder and welding. Now the mainstream of aerosol cans, food cans and beverage cans are produced by this method.

- Q: Can tinplate be used for packaging frozen foods?

- Yes, tinplate can be used for packaging frozen foods. Tinplate is a type of steel coated with a thin layer of tin, which provides protection against corrosion and keeps the food inside safe. It is commonly used in the food industry for various packaging applications, including frozen food containers. Tinplate containers offer good durability, insulation, and can withstand extremely low temperatures, making them suitable for packaging and preserving frozen foods.

- Q: How does tinplate affect the environment?

- Tinplate can have both positive and negative impacts on the environment. On one hand, tinplate is a highly recyclable material, which helps reduce waste and conserve resources. It can be recycled multiple times without losing its quality, making it an environmentally friendly choice. On the other hand, the production of tinplate involves energy-intensive processes and can result in the emission of greenhouse gases. Additionally, the mining of tin, one of the main components of tinplate, can have adverse effects on ecosystems and local communities. Therefore, while tinplate offers recycling benefits, its production and sourcing should be done responsibly to minimize its environmental impact.

- Q: Can tinplate be used for gift packaging?

- Yes, tinplate can be used for gift packaging. It is a versatile material that offers durability and can be easily shaped into various sizes and designs. Tinplate also provides a visually appealing and premium look, making it an excellent choice for gift packaging.

Send your message to us

ETP thickness from 0.30 to 0.35

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords