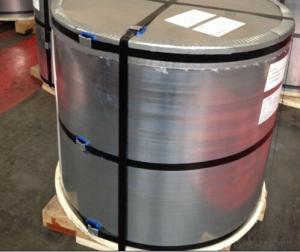

ETP thickness from 0.35 to 0.40

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main producers in Chinafor tinplate. At present, ourproductivity is about 450000 MT/year. Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, cleanenvironment to harvest the trust of the community, safety and health toconvince employees and energy-saving to be trusted by public". We areenjoying the trust and good name regarding to the superior quality and preferservice among the customers. Our products are sold nearly 150 enterprisesincluding Europe, America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

We has a customer service center whichproviding customers with whole-process service including the pre-sale, sale andafter-service, unified handling customer inquiries and complaints. CustomerService Center adhere to the goal “customer first and response rapidly” andarrange their service work according to the standard procedures. Ourcommitment: ready to accept advice and customer complaints, reply commentswithin 24 hours of treatment, when dealing with customer complaints of qualityissues, upon customer’s request, sent the inspector to the user site to saveproblem within 24 hours (within the province) and 48 hours (other provinces).

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. Tinplate is a versatile material that is durable, visually appealing, and can be easily customized with various designs. It offers a premium look and feel, making it an excellent choice for creating attractive promotional or gift packaging that can leave a lasting impression on recipients.

- Q: What are the typical manufacturing processes for tinplate products?

- The typical manufacturing processes for tinplate products include coil cutting, cleaning and coating, pressing or stamping, forming or shaping, welding or soldering, and final finishing or packaging.

- Q: How does tinplate perform in terms of light protection?

- Tinplate performs fairly well in terms of light protection. Its metal composition provides a good barrier against light, preventing the penetration of UV rays and reducing the risk of light-induced degradation or spoilage of the contents. However, its light protection capabilities may vary depending on the thickness and quality of the tin coating applied to the steel substrate.

- Q: How does tinplate compare to glass packaging?

- Tinplate packaging offers several advantages over glass packaging. Firstly, tinplate is lightweight and durable, making it easier and safer to transport. Additionally, tinplate is less prone to breakage, reducing the risk of product damage during handling or shipping. Tinplate also provides better protection against moisture, oxygen, and light, ensuring longer shelf life for packaged products. Moreover, tinplate is more cost-effective and environmentally friendly, as it is recyclable. Overall, tinplate packaging offers superior functionality, convenience, and sustainability compared to glass packaging.

- Q: Can tinplate be used for promotional and gift items?

- Yes, tinplate can be used for promotional and gift items. It is a versatile material that can be easily customized and printed on, making it ideal for creating unique and eye-catching promotional merchandise or personalized gifts. Tinplate items such as tin boxes, tin cans, or tin signs can be branded with logos, messages, or designs, making them an excellent choice for promotional and gift purposes.

- Q: How does tinplate packaging contribute to product convenience?

- Tinplate packaging contributes to product convenience by providing a durable and lightweight solution that is easy to handle and transport. It effectively protects the contents from external elements such as moisture, light, and air, ensuring the product's quality and longevity. Additionally, tinplate packaging often comes with easy-to-open features like pull tabs or twist-off caps, making it effortless for consumers to access the product. Its versatility allows for various shapes and sizes, making it suitable for a wide range of products across different industries.

- Q: What is the global demand for tinplate?

- The global demand for tinplate is significant and steadily growing due to its versatile applications across various industries, such as packaging, automotive, construction, and electronics. Tinplate's corrosion resistance, durability, and aesthetic appeal make it a preferred choice for manufacturing cans, containers, and other packaging materials. Additionally, the increasing focus on sustainability and recyclability has further boosted the demand for tinplate as it is highly recyclable.

- Q: What is the process for printing on tinplate?

- The process for printing on tinplate typically involves several steps. First, the tinplate sheets are cleaned and coated with a layer of primer to ensure proper adhesion of the ink. Then, the desired design or artwork is printed onto the tinplate using specialized printing techniques such as lithography or offset printing. After the printing is complete, the tinplate is usually coated with a protective varnish or lacquer to enhance its durability and resistance to corrosion. The printed tinplate sheets can then be further processed into various products, such as tin cans or decorative tin containers.

- Q: What are the regulations and standards related to tinplate packaging?

- The regulations and standards related to tinplate packaging vary depending on the country and industry. However, some common regulations and standards include ensuring the tinplate packaging materials are food-grade and safe for consumers, complying with labeling requirements such as product information and warnings, and meeting environmental regulations for packaging waste management. Additionally, tinplate packaging may need to adhere to specific industry standards like those set by the International Organization for Standardization (ISO) or specific regulatory bodies such as the United States Food and Drug Administration (FDA).

- Q: What are the different surface finishes available for tinplate?

- The different surface finishes available for tinplate include bright, stone, matte, and silver.

Send your message to us

ETP thickness from 0.35 to 0.40

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords