Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Tinplates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Tinplates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

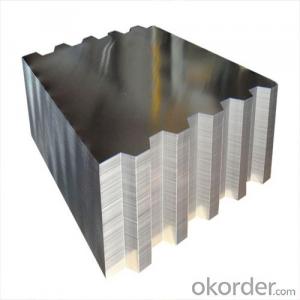

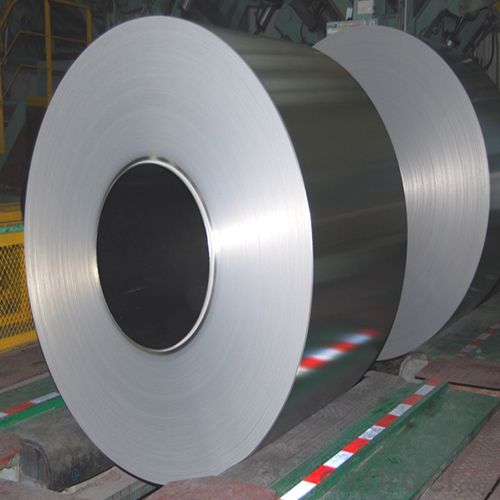

3. Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness Images

4.Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness Specification

Standard: ISO 11949 -1995

Material: MR

Thickness:0.34mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How is tinplate affected by different types of cosmetics?

- Tinplate can be affected by different types of cosmetics due to their chemical composition. Certain cosmetics, such as those containing acidic or alkaline ingredients, can cause corrosion or discoloration on the tinplate surface. Additionally, prolonged exposure to certain cosmetics, especially those containing solvents or oils, can lead to the degradation of the protective coating on the tinplate, making it more susceptible to rusting. Therefore, it is important to choose cosmetics that are compatible with tinplate packaging to ensure its longevity and integrity.

- Q: Can tinplate packaging be used for toy products?

- Yes, tinplate packaging can be used for toy products. Tinplate is a durable and versatile material that provides a protective barrier, making it suitable for packaging various types of toys. Additionally, tinplate can be easily printed on, allowing for attractive and customized designs for toy packaging.

- Q: What are the main challenges in tinplate transportation?

- The main challenges in tinplate transportation include ensuring proper packaging and securing of the tinplates to prevent damage during transit, managing the weight and volume limitations imposed by transportation regulations, coordinating logistics and transportation routes to minimize delivery times and costs, and addressing potential issues related to customs and import/export regulations for international shipments. Additionally, maintaining product quality and preventing contamination or corrosion during transportation are also important challenges to overcome.

- Q: How does tinplate contribute to the attractiveness of cosmetic packaging?

- Tinplate contributes to the attractiveness of cosmetic packaging by providing a sleek and shiny appearance. It adds a touch of elegance and sophistication to the packaging, making it visually appealing and enticing to consumers. The use of tinplate also allows for creative and intricate designs to be printed on the packaging, enhancing its overall aesthetic appeal. Additionally, tinplate's durability and resistance to corrosion ensure that the packaging remains in pristine condition, further enhancing the attractiveness of cosmetic products.

- Q: Can tinplate be used for hazardous material packaging?

- Yes, tinplate can be used for hazardous material packaging. Tinplate is a strong and durable material that provides a high level of protection against leakage, corrosion, and external impacts. It is commonly used for packaging hazardous materials such as chemicals, paints, and solvents, as it meets the required safety standards and regulations.

- Q: How does tinplate contribute to the shelf life of canned products?

- Tinplate contributes to the shelf life of canned products by providing a protective barrier between the food and the metal can. This barrier prevents the food from coming into direct contact with the metal, reducing the risk of corrosion and contamination. Additionally, tinplate's resistance to moisture and oxygen helps to maintain the product's freshness and prevent spoilage over an extended period of time.

- Q: Can tinplate be soldered?

- Yes, tinplate can be soldered. Tinplate is a steel sheet coated with a layer of tin, which makes it suitable for soldering. The tin coating provides good solderability, allowing for the joining of tinplate using soldering techniques.

- Q: How does tinplate perform in terms of recyclability?

- Tinplate is highly recyclable and has one of the highest recycling rates among packaging materials. It can be recycled indefinitely without losing its properties, making it an environmentally friendly choice.

- Q: What are the different types of tinplate surface treatments?

- There are several different types of tinplate surface treatments, including electrolytic tinplate (ETP), blackplate, tin-free steel (TFS), and lacquered tinplate.

- Q: What is the thickness range of tinplate?

- The thickness range of tinplate typically varies between 0.13mm to 0.49mm.

Send your message to us

Electrolytic Tinplate of Prime Quality for Chemical Industrial Use 0.34mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords