Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness Description

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

2.Main Features of the Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

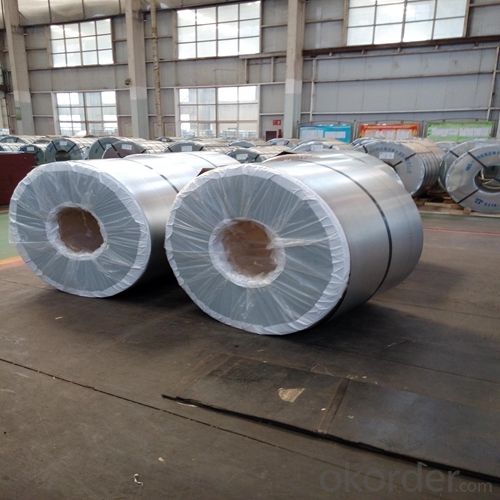

3.Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness Images

4.Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness Specification

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR

Thickness:0.19mm

Width: 600mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish

5.FAQ of Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: How does tinplate perform in terms of stackability?

- Tinplate performs well in terms of stackability due to its rigid and durable nature. Its flat surface and uniform thickness allow for easy stacking and stability, making it suitable for various storage and transportation applications.

- Q: How does tinplate perform in terms of impact resistance?

- Tinplate offers good impact resistance due to its sturdy and rigid composition. It can withstand moderate impacts without denting or deforming easily, making it a reliable choice for packaging and industrial applications.

- Q: What are the different grades of tinplate?

- The different grades of tinplate include Single Reduced (SR), Double Reduced (DR), and Electrolytic Chromium Coated Steel (ECCS).

- Q: Tinplate also known as what? What is the density of it?

- Tinplate, also known as tin plated iron, is the common name for tin plated steel sheet. The English abbreviation is SPTE. It is a cold-rolled low carbon steel sheet or strip coated with commercially pure tin on both sides. The density is 7.85.Tinplate is a tin covered with tin, it is not easy to rust, also known as tin iron.

- Q: How does tinplate contribute to the reduction of plastic waste?

- Tinplate contributes to the reduction of plastic waste by offering a sustainable alternative for packaging. Tinplate containers, such as cans, are widely used for storing food, beverages, and other products, eliminating the need for single-use plastic packaging. These containers are recyclable and have a high recycling rate, diverting a significant amount of waste from landfills. Additionally, tinplate's durability and protective properties help extend the shelf life of products, reducing food waste and the need for excessive packaging.

- Q: What are the different tinplate finishes available?

- There are several different tinplate finishes available, including bright, stone, matte, and lacquered. These finishes offer varying levels of shine, texture, and protection to the tinplate surface.

- Q: Can tinplate be painted?

- Yes, tinplate can be painted.

- Q: What are the main differences between tinplate and tinplate laminates in terms of shelf life?

- The main difference between tinplate and tinplate laminates in terms of shelf life is that tinplate laminates offer better protection against external factors such as moisture and oxygen. The lamination process involves bonding a layer of plastic or other materials to the tinplate, providing an additional barrier against corrosion and contamination. This enhanced protection helps to extend the shelf life of products packaged in tinplate laminates compared to those in regular tinplate.

- Q: What are the advantages of using tinplate for medical packaging?

- Some advantages of using tinplate for medical packaging include its durability, resistance to corrosion, and ability to maintain the integrity of the packaged product. Tinplate also provides a barrier against moisture, light, and oxygen, which helps in preserving the quality and shelf life of medical products. Additionally, tinplate is recyclable, making it an eco-friendly choice for packaging.

- Q: How is tinplate affected by exposure to UV light?

- Tinplate is generally not affected by exposure to UV light as it is a highly durable and corrosion-resistant material. However, prolonged exposure to intense UV radiation may cause minor color fading or surface discoloration over an extended period of time.

Send your message to us

Electrolytic Tinplate of Prime Quality for Food Cans Use 0.19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords