All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

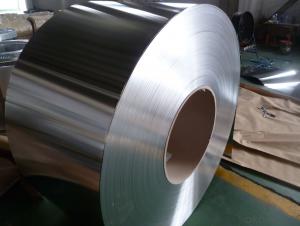

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the potential regulations or standards for electrolytic tinplate coil in different industries?

Potential regulations or standards for electrolytic tinplate coil in different industries may include specific requirements for the tin coating thickness, uniformity, adhesion, and corrosion resistance. These regulations could vary depending on the industry, such as food packaging, automotive, or electronics. Additionally, standards may exist regarding the use of environmentally friendly tin coatings, compliance with health and safety regulations, and adherence to quality control measures.

How should electrolytic tinplate coil be stored?

Electrolytic tinplate coil should be stored in a clean, dry, and well-ventilated area to prevent moisture and corrosion. It is advisable to keep the coils on pallets or racks, away from direct contact with the floor, and to stack them in a way that avoids excessive pressure or damage. Additionally, storing the coils away from chemicals or substances that may cause contamination is crucial for maintaining their quality and preventing any potential hazards.

What are the common surface defects that can occur in electrolytic tinplate coil?

Common surface defects that can occur in electrolytic tinplate coil include scratches, rust spots, pinholes, black spots, and uneven coating thickness.

What are the different applications of electrolytic tinplate coil?

Electrolytic tinplate coils have various applications in industries such as food packaging, beverage cans, aerosol cans, and electronic components. The tin coating on these coils provides corrosion resistance, making them suitable for storing and preserving food items. The coils are also commonly used in manufacturing tin cans for beverages and aerosol products. Additionally, the electrical conductivity of electrolytic tinplate makes it ideal for producing electronic components such as capacitors and resistors.

Wholesale Electrolytic Tinplate Coil from supplier in United Arab Emirates

We understand the importance of quality and reliability when it comes to Electrolytic Tinplate Coils, and we strive to meet the highest industry standards. Our team of experts is dedicated to assisting you throughout the entire procurement process, from product selection to delivery.

Whether you are in the food packaging, construction, or automotive industry, we have the right Electrolytic Tinplate Coil products to meet your specific requirements. Our range includes various thicknesses, widths, and coatings to ensure that we can cater to diverse applications.

In addition to our wide product range, we also offer competitive pricing and flexible payment terms to ensure that you receive the best value for your investment. We understand the importance of timely delivery, and our logistics team works diligently to ensure that your orders reach you on time and in excellent condition.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to offer a comprehensive range of Electrolytic Tinplate Coil products. Our strong relationship with these partners enables us to negotiate favorable terms and ensure consistent product quality.

We take pride in providing exceptional customer service and technical support. Our team of professionals is always available to answer any questions you may have and provide guidance throughout the procurement process. Whether you need assistance with product selection, technical specifications, or any other aspect, we are here to help.

Partnering with us means gaining a reliable and trusted supplier for all your Electrolytic Tinplate Coil needs in the UAE. Contact us today to discuss your requirements and experience the quality and service that sets us apart.

Whether you are in the food packaging, construction, or automotive industry, we have the right Electrolytic Tinplate Coil products to meet your specific requirements. Our range includes various thicknesses, widths, and coatings to ensure that we can cater to diverse applications.

In addition to our wide product range, we also offer competitive pricing and flexible payment terms to ensure that you receive the best value for your investment. We understand the importance of timely delivery, and our logistics team works diligently to ensure that your orders reach you on time and in excellent condition.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to offer a comprehensive range of Electrolytic Tinplate Coil products. Our strong relationship with these partners enables us to negotiate favorable terms and ensure consistent product quality.

We take pride in providing exceptional customer service and technical support. Our team of professionals is always available to answer any questions you may have and provide guidance throughout the procurement process. Whether you need assistance with product selection, technical specifications, or any other aspect, we are here to help.

Partnering with us means gaining a reliable and trusted supplier for all your Electrolytic Tinplate Coil needs in the UAE. Contact us today to discuss your requirements and experience the quality and service that sets us apart.