Equal Angle Steel Cold Rolled for Constraction Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Steel Cold Rolled for Constraction Application at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Cold Rolled for Constraction Application are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Cold Rolled for Constraction Application are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

304stainless steel angle bar

1.Short time delievry

2.Length:1-12M

3 New produced product, few rust

4 provide your Logo

Hot rolled 304stainless steel angle bar from China ShangHai

Hot rolled 304stainless steel angle bar from China ShangHai | |

| Size | 25mm*25mm-250mm*250mm (Customized size is acceptable, pls contact supplier for more details) |

Wall thickness | 3mm-20mm |

Length | 1m-12m ,Can follow customer’s requiremnts |

Internatioanal Standard | ISO 9001-2008 |

Standards |

ASTMA53/ASTM A573/ASTM A283/Gr.D/

BS1387-1985/

GB/T3091-2001,GB/T13793-92, ISO630/E235B/

JIS G3101/JIS G3131/JIS G3106/

|

Materials |

(We could offer Carbon, Alloy, Stainless steel) Q195,Q215,Q235B,Q345B,

S235JR/S235/S355JR/S355

SS440/SM400A/SM400B

MTC report will be offered together with the shipping document. |

Product Category | Metallurgy,Mineral &Energy |

Technique | Hot Rolled |

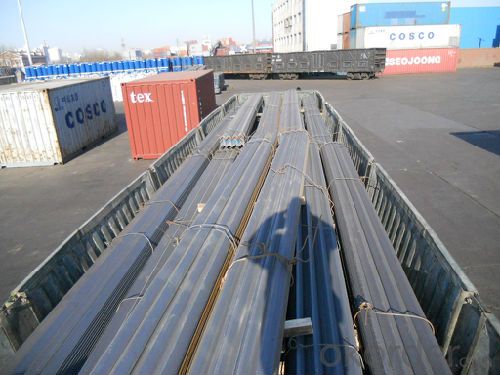

Packing | 1.Big OD:in bulk 2.Small OD:packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical&manufacture,Steel strcuture, Shipbuilding,Bridging,Automobile chassis , Power tower, frame shef |

Main market | Middle East, Asia, Africa,Europe, America and Australia |

Country of origin | China |

Productivity | 15000 Metric Tons pet Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 10 tons Lead time: 3-15 working days (Can Fast delievery time because of the large stock size and well experience in the whole process of the international export business in this feild) |

Company Advantage

| 1, Fast response in reply 2, Good sales with reasonable price. 3, Good quality materials. 4, Fast lead time. 5, Rich experience in export business. 6, Well after sales service. 7, Flexible policy. |

Materials Workability | Easy to Weld, Cut, Form, and Machine |

Another Name | angle steel bar ,angle steel , steel angle , mild steel angle ,carbon steel bars, 304stainless steel angle bar |

Other processing service | Hot dipped Galvanized, pre-galvanized, coated, cutting, bending,punching as long as u could tell us the requirment. |

Shipment |

1, 1-10 tons it's ok to go by LCL

|

Other fittings

| Bolt with Anti-thift nut or any other required fittings (small amount order is acceptable) |

Contact

| TEL: +86-021-62153163 FAX: +86-021-62152536 (Good english speaking sales, welcome to call us if there has any questions. |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Are steel angles suitable for seismic design?

- Yes, steel angles are commonly used in seismic design. Steel angles offer several advantages that make them suitable for seismic design. Firstly, steel angles have a high strength-to-weight ratio, which means they can withstand high levels of seismic forces while being relatively lightweight. This is important in seismic design as it allows for the construction of structures that can absorb and dissipate seismic energy efficiently. Secondly, steel angles have excellent ductility, which is the ability to deform without breaking. During an earthquake, structures undergo significant deformations due to ground shaking. Steel angles can absorb these deformations by flexing and bending without compromising their structural integrity. This ductility helps in dissipating the seismic energy and prevents the sudden collapse of the structure. Additionally, steel angles can be easily connected and fabricated, allowing for efficient construction in seismic zones. They can be welded or bolted together to create rigid connections that can resist seismic forces. The versatility of steel angles allows for the design of various structural elements, such as braces, beams, and columns, that can effectively withstand seismic loads. Furthermore, steel angles are highly durable and resistant to corrosion, which is crucial in seismic design. Structures in seismic zones are often exposed to harsh environmental conditions, including moisture and corrosive agents. Steel angles can withstand these conditions and maintain their structural integrity over time. In conclusion, steel angles are suitable for seismic design due to their high strength-to-weight ratio, excellent ductility, ease of fabrication, and resistance to corrosion. These properties make steel angles a reliable choice for constructing structures that can withstand and safely absorb seismic forces.

- Q: Can steel angles be used for machine guards?

- Yes, steel angles can be used for machine guards. Steel angles are commonly used in the construction industry for their strength and durability. They can be easily fabricated and installed to create a protective barrier around machinery, ensuring the safety of workers and preventing accidents. The versatility of steel angles allows them to be customized to fit various machine sizes and shapes. Additionally, steel angles offer good impact resistance and can withstand heavy loads, making them suitable for use in machine guarding applications.

- Q: How do you design connections for steel angles to steel beams?

- Designing connections between steel angles and steel beams requires careful consideration and a step-by-step approach. Here is a general overview of the process: 1. Load determination: The first step involves identifying the loads that will impact the connection. These include vertical and horizontal loads, as well as any moments applied. These loads are crucial in determining the required strength of the connection. 2. Selection of appropriate materials: Based on the loads and design criteria, suitable steel angles and beams must be chosen for the connection. Factors such as material grade, size, and shape should be taken into account. 3. Connection analysis: The connection is analyzed to determine the necessary strength. This involves calculating shear, moment, and axial forces that will act on the connection. Structural analysis methods are employed, considering both service loads and ultimate strength requirements. 4. Connection type determination: Once the analysis is complete, the appropriate connection type is selected. Common options include bolted, welded, or a combination of both. Factors such as available space, ease of construction, and structural requirements are considered. 5. Connection design: The connection is designed to meet the required strength and performance criteria. This includes determining the number, size, and layout of bolts or welds, as well as any additional reinforcement or stiffeners that may be necessary. Shear, moment, and axial force resistance, along with adherence to design codes and standards, are considered. 6. Detailing and fabrication: Detailed drawings and specifications, including dimensions, tolerances, and material specifications, are provided for the connection. Coordination with fabricators and contractors ensures accurate fabrication and installation. 7. Quality control and inspection: Throughout fabrication and construction, quality control checks and inspections are conducted to ensure correct fabrication and installation of the connection. Visual inspections, non-destructive testing, and load testing, if required, are performed. Consulting with a structural engineer or experienced professional in steel connection design is essential to ensure the connection is designed safely and complies with applicable building codes and standards.

- Q: Can steel angles be used in curtain wall construction?

- Yes, steel angles can be used in curtain wall construction. Steel angles are commonly used as structural supports and framing elements in curtain wall systems. They provide stability, strength, and durability to the overall structure, allowing for the installation of glass panels or other cladding materials.

- Q: What are the different testing methods for steel angles?

- There are several testing methods for steel angles, including visual inspection, dimensional measurement, hardness testing, chemical analysis, and mechanical testing. Visual inspection involves examining the angles for any visual defects or irregularities. Dimensional measurement ensures that the angles meet the specified size and shape requirements. Hardness testing determines the hardness of the steel, which is an important factor in its strength and durability. Chemical analysis is performed to check the composition and purity of the steel, ensuring that it meets the required standards. Mechanical testing involves subjecting the steel angles to various loads and stresses to evaluate their mechanical properties such as strength and ductility.

- Q: What are the different types of surface defects in steel angles?

- There are several different types of surface defects that can occur in steel angles. These defects can affect the appearance, strength, and overall quality of the steel. Some common types of surface defects in steel angles include: 1. Scale: Scale refers to the formation of a thin layer of iron oxide on the surface of the steel. It is commonly caused by the exposure of the steel to high temperatures during manufacturing or processing. Scale can affect the appearance of the steel and can also lead to corrosion if not removed. 2. Pits: Pits are small depressions or cavities on the surface of the steel. They can be caused by a variety of factors, including corrosion, improper handling, or manufacturing defects. Pits can weaken the steel and reduce its overall strength. 3. Scratches: Scratches are grooves or marks on the surface of the steel caused by abrasion or contact with other objects. While scratches may not affect the structural integrity of the steel, they can impact its appearance and may provide a starting point for corrosion. 4. Inclusions: Inclusions are non-metallic particles or impurities that are trapped within the steel during the manufacturing process. They can be caused by a variety of factors, such as improper steelmaking techniques or the presence of foreign materials. Inclusions can weaken the steel, leading to reduced strength and potential failure under load. 5. Laminations: Laminations are layers or sheets of metal that are not properly bonded together during the manufacturing process. They can occur due to improper rolling or welding techniques. Laminations can weaken the steel, reducing its strength and potentially causing failure. 6. Corrosion: Corrosion is a chemical reaction that occurs when steel is exposed to moisture and oxygen. It can result in the formation of rust or other corrosion products on the surface of the steel. Corrosion can weaken the steel and reduce its overall integrity. It is important to identify and address these surface defects in steel angles to ensure the quality and performance of the steel. Regular inspection, proper handling, and appropriate surface treatment can help minimize the occurrence and impact of these defects.

- Q: Can steel angles be used in curtain wall or facade systems?

- Certainly, curtain wall or facade systems can indeed incorporate steel angles. These versatile structural elements possess the ability to offer support, stability, and aesthetic allure to curtain walls or facades. They can be employed as framing components to construct the structural framework of the system or as brackets to connect different elements. Steel angles possess outstanding strength and durability, enabling them to withstand the various loads and forces exerted upon curtain walls or facades. Moreover, steel angles can be tailor-made in terms of dimensions, shape, and finish to fulfill the precise design specifications of the project.

- Q: What are the common installation methods for steel angles?

- The common installation methods for steel angles include welding, bolting, and using adhesive.

- Q: What are the different types of steel angles used in automotive engineering?

- There are several types of steel angles used in automotive engineering, including equal angles, unequal angles, and L-shaped angles. These angles are commonly used for structural support, reinforcement, and to provide strength and stability to various components of the vehicle.

- Q: What are the different types of corrosion that can affect steel angles?

- There are several types of corrosion that can affect steel angles, including: 1. Uniform corrosion: This is the most common type of corrosion and occurs when the entire surface of the steel angle corrodes evenly. It is typically caused by exposure to moisture and oxygen in the environment. 2. Pitting corrosion: Pitting corrosion is characterized by the formation of small pits or holes on the surface of the steel angle. It occurs when localized areas of the metal are exposed to more aggressive corrosive agents, such as chloride ions or acidic substances. 3. Galvanic corrosion: Galvanic corrosion happens when two different metals are in contact with each other in the presence of an electrolyte, such as water or saltwater. The more active metal (the anode) corrodes while the less active metal (the cathode) remains protected. 4. Crevice corrosion: Crevice corrosion occurs in confined spaces or crevices where stagnant water or moisture can accumulate. The lack of oxygen and the concentration of corrosive agents can lead to localized corrosion and degradation of the steel angle. 5. Filiform corrosion: This type of corrosion appears as thread-like filaments that form on the surface of the steel angle. It is typically caused by the presence of moisture and oxygen, as well as the presence of contaminants such as salts or organic compounds. 6. Stress corrosion cracking: Stress corrosion cracking occurs when a combination of tensile stress and a corrosive environment causes cracks to form in the steel angle. It can be particularly dangerous as it can lead to sudden and catastrophic failure of the structure. It is important to note that the severity and likelihood of each type of corrosion can vary depending on factors such as the environment, exposure to corrosive agents, and the quality of the steel angle itself. Regular inspection, maintenance, and appropriate protective coatings can help mitigate the effects of corrosion on steel angles.

Send your message to us

Equal Angle Steel Cold Rolled for Constraction Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords