Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

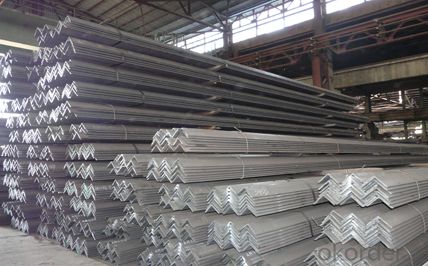

OKorder is offering Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1,Material:Angle Steel

2,Payments:T/T or L/C

3,MOQ:1 Metric Ton

4,Delviery Time: In 30 days

5,Certificate:ISO,BV,LR,MTC.

Material: Q235B/SS 400/A-36 Angle Steel

Standards:ASTM,JIS,GB,EN(DIN,BS,NF) Or Per as clients' requires.

| Material | Q195,Q235,Q345, Grade D,SS400,S235JR,1.0038,304,316,316L,201,202,410,420,ETC |

| Standards | GB/T 13793-1992 ,ASTM,JIS,EN 10025 ETC |

| Origin place | Made In China |

| Delivery Condition | Hot rolled |

| Surface require | Black,Hot Dipped Galvanization,Polish |

| Packing | 1.Seaworthy Packing 2.Wooden Case 3.Carton,Woven Bag Or At Client's Requires |

| Delivery time | In 10-30 days |

| Trade Term | EXW,FOB,CIF |

| Payments | T/T or L/C at sight |

| Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

| MOQ | 1 Ton |

| Product Advantages | 1.Very Fast Delivery Time 2.High Quality And Reasonable Price 3.Sizes Are Enough 4.Many In stocks In warehouse 5.Provide The Sample For Free |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel angles be cut to size?

- Certainly! Steel angles are capable of being cut to the desired size. These versatile structural materials, commonly referred to as L-shaped angles, find extensive use in the construction and manufacturing sectors. One can effortlessly tailor their length using a variety of cutting tools such as saws, plasma cutters, or angle grinders. This enables customization and guarantees a seamless fit for the steel angles in their intended purpose. It is crucial to adhere to suitable safety precautions and utilize appropriate equipment while cutting these angles, given their formidable strength and durability.

- Q: Can steel angles be used for support columns in building construction?

- Steel angles can indeed be utilized as support columns in building construction. Their strength, durability, and versatility render them frequently employed in construction. When employed as columns, they offer exceptional support and stability, particularly in structures of small to medium size. Furthermore, steel angles can be easily fabricated and tailored to satisfy precise design criteria. They also boast resistance against fire, corrosion, and pests, signifying their dependability as support columns in building construction.

- Q: Are steel angles suitable for earthquake-resistant construction?

- Yes, steel angles are suitable for earthquake-resistant construction. Steel angles have high strength and stiffness, which enables them to withstand the lateral forces and dynamic loads generated during an earthquake. They can be used in various structural elements, such as moment-resisting frames and bracing systems, to provide stability and resistance against seismic forces. Additionally, steel angles can be easily fabricated and installed, making them a popular choice in earthquake-resistant construction.

- Q: How do you prevent steel angles from rusting?

- There are several methods to prevent steel angles from rusting: 1. Protective Coatings: Applying a protective coating on the surface of steel angles is an effective way to prevent rust formation. Common coating options include paint, epoxy, enamel, and galvanized coatings. These coatings act as a barrier, preventing moisture and oxygen from reaching the steel surface, thus minimizing the chances of rusting. 2. Rust Inhibitors: Rust inhibitors are chemical compounds that can be applied to steel angles to prevent rust formation. These inhibitors work by either forming a protective layer on the steel surface or by actively inhibiting the corrosion process. Rust inhibitors can be applied as sprays, coatings, or even added to the steel during the manufacturing process. 3. Proper Storage and Handling: One of the simplest ways to prevent rust is to store and handle steel angles properly. This includes keeping them in a dry environment, preferably indoors or under a protective covering, to avoid exposure to moisture and humidity. Additionally, handling steel angles with clean, dry gloves can prevent the transfer of moisture from hands, which can accelerate the rusting process. 4. Regular Maintenance: Regular inspection and maintenance of steel angles can help identify and address any signs of rust formation at an early stage. Promptly addressing any rust spots by removing them with wire brushes or sandpaper and applying touch-up coatings can prevent further corrosion. 5. Dry Storage and Proper Ventilation: If steel angles are stored outdoors, it is crucial to ensure they are placed in a well-ventilated area to promote air circulation and prevent the accumulation of moisture. Furthermore, covering the angles with a waterproof tarp or plastic wrap can provide an additional layer of protection against rain, snow, and other weather elements. By implementing a combination of these preventive measures, steel angles can be safeguarded against rust formation, ensuring their longevity and structural integrity.

- Q: Are steel angles subject to deformation?

- Yes, steel angles can be subject to deformation under certain conditions. The extent of deformation depends on various factors such as the load applied, the quality of the steel, and the design of the angle. However, steel angles are generally known for their strength and resistance to deformation compared to other materials.

- Q: What does 50*50*5 angle mean?

- Standard Specification for angle iron: indicated by width mm * width * * edge mm.

- Q: What are the common design codes or standards for steel angles?

- There are several common design codes and standards that govern the use of steel angles in structural design. These codes and standards ensure that the angles are designed and manufactured to meet certain safety and performance criteria. One of the most widely used design codes for steel angles is the American Institute of Steel Construction (AISC) Manual of Steel Construction. The AISC provides comprehensive guidelines and specifications for the design, fabrication, and erection of steel structures, including angles. This manual includes detailed information on the design strength, allowable stress levels, and geometric properties of angles. In addition to the AISC Manual, other design codes and standards may also be applicable depending on the specific project and location. These include international standards such as the Eurocode, British Standards (BS), and Australian Standards (AS). Each of these standards may have slightly different requirements for the design and use of steel angles, so it is important to consult the appropriate standard for the specific project. Furthermore, the American Society for Testing and Materials (ASTM) has established standards for the physical and mechanical properties of steel angles. These standards ensure that the angles meet certain quality and performance requirements. The most commonly used ASTM standard for steel angles is ASTM A36, which specifies the general requirements for carbon structural steel. Overall, the common design codes and standards for steel angles provide guidance on factors such as load capacity, strength, and safety considerations. Adhering to these codes and standards ensures that steel angles are designed and used in a manner that promotes structural integrity and reliability.

- Q: Can steel angles be bent or shaped?

- Yes, steel angles can be bent or shaped using specialized equipment and techniques such as heat bending, cold bending, or roll forming.

- Q: Can steel angles be used in curtain wall systems?

- Yes, steel angles can be used in curtain wall systems. Steel angles are commonly used as support brackets or mullions in curtain wall systems. They provide structural strength and support to the glass panels or other cladding materials. Steel angles can be fabricated in various sizes and shapes to accommodate the specific design requirements of the curtain wall system. Additionally, steel angles can be welded or bolted together to create the desired framework for the curtain wall. Overall, steel angles offer a durable and reliable option for incorporating into curtain wall systems.

- Q: Can steel angles be used in oil and gas pipeline installations?

- Yes, steel angles can be used in oil and gas pipeline installations. Steel angles are commonly used as structural supports in various industries, including the oil and gas sector. They provide strength and stability to pipeline installations, helping to ensure the integrity and safety of the infrastructure. Steel angles are known for their high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for demanding environments such as oil and gas pipelines. Additionally, steel angles can be easily welded or bolted together, allowing for efficient and cost-effective installation. Overall, steel angles are a reliable and commonly used component in oil and gas pipeline installations.

Send your message to us

Equal Angle Steel China Direct Factory Price with ASTM JIS DIN Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords