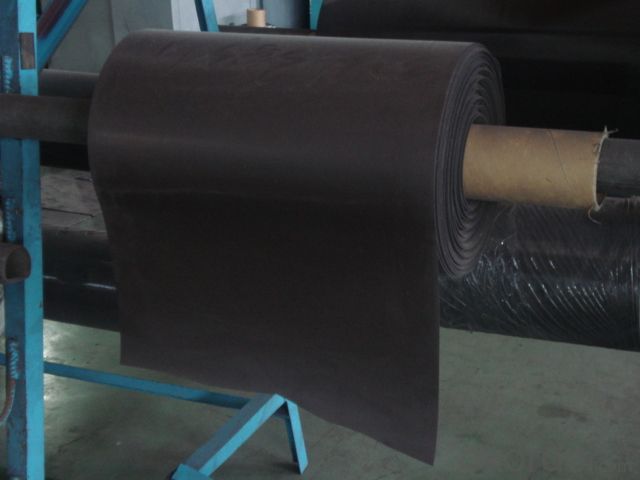

EPDM Waterproofing Membrane for Under Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product instruction

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Detailed Product Description

1. High adhesive strength, durability, long after the bond;

2.Excellent weathering resistance, aging resistance;

3. Nano stabilizer added ingredients, low heat dimensional change;

4. High tensile strength, elongation, strong grass-roots stretching or cracking adaptability, resistance to low temperatures, can be adapted to -40 ℃;

5.Cold installation, easy to operate, reduce environmental pollution and improve working conditions of workers;

Application

EPDM (TBD) selfadhesive waterproofing membrane used in roofing projects, exposed roofing, building foundations, basements, storage tanks, subways, tunnels, supermarkets, airports and other buildings waterproof.

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used in steam rooms?

- Yes, a waterproofing membrane can be used in steam rooms. A waterproofing membrane is designed to prevent water infiltration and is commonly used in areas where moisture is present, such as bathrooms, showers, and steam rooms. The membrane acts as a barrier, preventing water vapor from penetrating the underlying structure and causing damage. In steam rooms, where high levels of humidity and moisture are present, using a waterproofing membrane is essential to protect the walls, floors, and other surfaces from water damage and mold growth. It is important to choose a waterproofing membrane that is specifically designed for high moisture environments like steam rooms to ensure proper protection and longevity. Additionally, proper installation and adherence to manufacturer guidelines are crucial for the effectiveness and durability of the waterproofing membrane in a steam room setting.

- Q: Can a waterproofing membrane be applied to horizontal surfaces?

- Yes, a waterproofing membrane can be applied to horizontal surfaces.

- Q: Can a waterproofing membrane be applied in cold weather?

- Yes, a waterproofing membrane can be applied in cold weather. However, there are certain considerations that need to be taken into account. It is important to use a membrane that is specifically designed for cold weather applications as some membranes may not perform optimally in low temperatures. Cold weather can affect the curing process of the membrane, so it is crucial to follow the manufacturer's guidelines regarding temperature limitations and application techniques. The surface to be waterproofed should also be clean and dry before applying the membrane, as moisture or ice can interfere with adhesion. In cold weather, it may take longer for the membrane to fully cure and achieve its maximum performance. Therefore, it is advisable to allow sufficient time for the membrane to dry and cure before exposing it to water or other stressors. It is also important to note that extreme cold temperatures can negatively impact the installation process and the overall effectiveness of the waterproofing system. Therefore, it is recommended to consult with a professional waterproofing contractor who has experience working in cold weather conditions to ensure the best results.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Tunnels equipped with fire protection systems can indeed make use of a waterproofing membrane. It is actually quite common to recommend the use of a waterproofing membrane alongside fire protection systems in tunnels, as it adds an extra layer of safeguarding. The purpose of this membrane is to prevent any water from infiltrating the tunnel, as this could potentially harm the fire protection systems and undermine their effectiveness. By ensuring the tunnel remains watertight, the waterproofing membrane preserves the integrity and functionality of the fire protection systems, enabling them to fulfill their intended purpose in the event of a fire. Moreover, the waterproofing membrane can also serve as a barrier, impeding the spread of fire by blocking the passage of flames and smoke. Nonetheless, it is crucial to ensure that the chosen waterproofing membrane is compatible with the specific fire protection systems employed in the tunnel in order to ensure optimum performance and safety.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide durability and protect the underlying structures from water damage. They are often used in areas such as basements, balconies, and rooftops, which may experience heavy foot traffic or support heavy loads. However, it is important to choose a membrane specifically designed for high traffic or heavy load areas to ensure it can withstand the intended use.

- Q: How does a waterproofing membrane handle movement or settling of a building?

- A waterproofing membrane is designed to handle movement or settling of a building through its flexibility and elasticity. It can stretch and contract with the building's movements, ensuring that the membrane remains intact and effective in preventing water infiltration. This flexibility allows the membrane to accommodate any minor shifts or settling that may occur over time, maintaining its waterproofing properties and protecting the structure from water damage.

- Q: Can a waterproofing membrane be used for art installations or sculptures?

- Indeed, the utilization of a waterproofing membrane is applicable for art installations and sculptures. In the realm of construction projects, waterproofing membranes are commonly employed to ward off water infiltration and safeguard surfaces from potential moisture damage. Concerning art installations and sculptures, a waterproofing membrane can furnish added durability and fortification against environmental factors like rain, snow, or humidity. This becomes particularly crucial for outdoor installations or sculptures that are exposed to the elements. Furthermore, the implementation of a waterproofing membrane can aid in preserving the artwork's integrity and longevity, ensuring its enduring visual appeal and structural soundness. Nevertheless, it is imperative to seek guidance from professionals or experts in the field of waterproofing to ensure the appropriate selection and application of the membrane, as certain artistic materials or techniques may necessitate specific types.

- Q: Are waterproofing membranes resistant to chemicals?

- Waterproofing membranes are generally resistant to chemicals, providing a protective barrier against water infiltration. These membranes are typically made from materials like PVC, TPO, or EPDM, which possess excellent chemical resistance properties. Their engineering ensures they can endure exposure to various chemicals like acids, alkalis, solvents, and oils without deteriorating. This chemical resistance guarantees that waterproofing membranes can maintain their integrity and effectiveness even in environments with common chemical exposure, such as industrial settings, laboratories, or chemical storage areas. However, it is important to consider that the specific chemical resistance capabilities may differ based on the type and quality of the chosen waterproofing membrane. Therefore, it is crucial to select the appropriate membrane that matches the project's specific chemical exposure requirements.

- Q: Are waterproofing membranes resistant to thermal expansion?

- Indeed, waterproofing membranes exhibit resistance to thermal expansion. These membranes are specifically engineered to endure temperature fluctuations without compromising their integrity or functionality. Their composition includes materials with exceptional thermal stability and minimal thermal expansion coefficients, enabling them to expand and contract without any detrimental effects or jeopardizing their waterproofing capabilities. This resistance against thermal expansion plays a pivotal role in guaranteeing the effectiveness and long-lasting durability of the waterproofing membrane, regardless of extreme weather conditions such as extreme heat or cold.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Yes, a waterproofing membrane can be used in stadiums or sports complexes to protect the structural elements from water damage and prevent leaks.

Send your message to us

EPDM Waterproofing Membrane for Under Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords