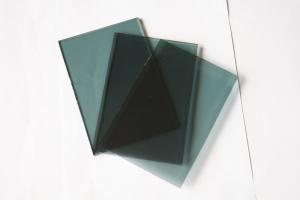

Engraved Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Engraved Glass is a kind of glass with the new processing. We can process the surface of glass like V-groove and U-groove, which looks like beveled glass but not the same.

Features:

Thousands of designs and patterns:

Specifications:

Thickness: 5-25mm

Size: customized size

Applications:

Engraved Glasshas been widely used on square, high-grade office building, private villa, club, hotel, restaurant and furniture decoration such as background wall, aisle, pole, etc.

- Q: List and characteristics of chimney glass flake cement

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake could commission a heat stable layer, which can prevent the substrate cracking and spalling.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- With the progress of science development, composition and characteristics of glass and glass gradually get more understanding, research and development and production scale also has a good improvement, people can use a variety of silica sand quality production of a variety of uses a glass. Manufacture of optical glass, silica sand with high quality special glass, crystal glass, with medium quality silica sand production of flat glass, can also be used for sand production of colored glass, and according to the national defense and economic construction, research and development, production of various types of special glass

- Q: Acrylic plexiglass rod can be used in what way?

- Plexiglass sticks, which cheap plexiglass bonding is an important process, to enhance product quality and taste, affected by two aspects, one is adhesive; two is adhesive skills.

- Q: Tile selection, paving process

- The base should be clean, irregularities to chisel and repair, base should be clean, not a mortar, especially lime mortar, oil, and water wet ground.When laying stone or ceramic tile, standard blocks shall be placed. Standard blocks shall be placed at the intersection of cross lines and diagonally installed.Paving operation to each line in line, the stone must be soaking wet, dry wipe back.

- Q: There are several appearances of the quality defects of ordinary flat glass

- If molten glass contains gas, it forms bubbles when it is formed. Bubbles mainly affect the transmittance of glass, reduce the mechanical properties of glass, but also affect people's vision, resulting in deformation of the biological image, the main reason is that the purity of raw materials is not enough.

- Q: The difference between glass wool, rock wool, mineral wool

- 1., raw materials are different: to metallurgical slag or fly ash as the main raw material called slag cotton; basalt and other rock as the main raw material called "rock wool"".2. the coefficient of acidity of rock wool and slag cotton is also different. Rock wool acidity coefficient MK generally greater than 1.5, and even up to more than 2; slag cotton MK generally can only be maintained at around 1.2, it is difficult to more than 1.3.3. because of the difference between chemical composition and acidity coefficient of rock wool and slag cotton, they also show some differences in performance.(1) the difference of water resistance(2) difference of heat resistance;(3) difference in corrosion resistance

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- The production of glass bottles industry, its raw materials are stone powder, quartz sand, soda ash, waste glass and coalA variety of materials used in the preparation of glass batch, collectively referred to as glass raw materials. In general by the 7-12 component, the main material is 4-6, such as quartz sand, limestone, feldspar, sodium carbonate, boric acid, lead compounds, barium compounds, according to the introduction of oxides in the glass structure effect, can be divided into glass forming oxide materials, intermediate oxide materials, network oxides materials, according to the the properties of oxide, can be divided into raw material, acid alkali metal oxide oxide materials. The glass batch is obtained some necessary properties and accelerate the melting process of raw materials, although less, but it is very important that these materials as clarifying agent, fluxing agent, coloring agent, bleaching agent, emulsifying agent, oxidizing agent and reducing agent etc..The same raw materials, different formulations, the same raw materials, different habitats and different indicators, will affect product quality and production costs. In the case of a small gap in raw material costs, the glass bottles produced are very different from each other in the comparison of small samples, and the difference can only be seen in batch production.

- Q: Are there any materials that need to be tested in curtain work?

- Main profiles (including aluminum and steel profiles), screws, bolts, drawing test, four test, hardware fittings, etc.

- Q: What materials do you need to make glass?

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures.

- Q: What is quartz made of?

- 7, electronic high purity silicon metal, optical fiber 8, rubber and plastic filler (which can improve the wear resistance of 9), paint filler (which can improve the weatherability of coatings) 10, aerospace and aviation, the internal structure of molecular chain, crystal shape and lattice changes, make its temperature resistance, coefficient of thermal expansion small, high insulation, corrosion resistance, piezoelectric effect, resonance and its unique optical properties.

1. Manufacturer Overview

| Location | Qianghuangdao, China |

| Year Established | 1995 |

| Annual Output Value | Above US$50 Million |

| Main Markets | North America |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Engraved Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords