Hindalco Aluminum Roofing Sheets - EN AW-5083 Aluminium Panel for Oil Tanker Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW-5083 Aluminium Panel for Making Oil Tanker Description

EN AW-5083 Aluminium Panel for Making Oil Tanker is one semi-finished aluminium material. The alloy AA5083 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW-5083 Aluminium Panel for Making Oil Tanker

EN AW-5083 Aluminium Panel for Making Oil Tanker | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW-5083 Aluminium Panel for Making Oil Tanker

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW-5083 Aluminium Panel for Making Oil Tanker

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW-5083 Aluminium Panel for Making Oil Tanker

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

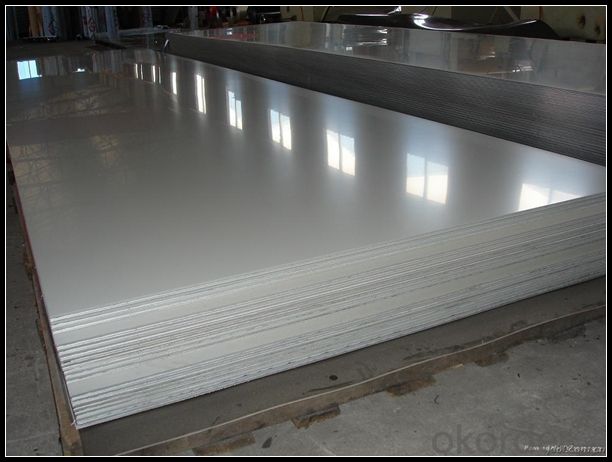

6. Image of EN AW-5083 Aluminium Panel for Making Oil Tanker

7. Package and shipping of EN AW-5083 Aluminium Panel for Making Oil Tanker

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the limitations of using aluminum sheet?

- There are several limitations associated with using aluminum sheet in various applications. Firstly, aluminum is a relatively soft metal compared to other options such as steel or titanium. This means that it is more susceptible to scratches, dents, and deformation under heavy loads or impacts. Therefore, it may not be suitable for applications that require high strength or resistance to damage. Secondly, aluminum has lower thermal conductivity compared to other metals. This can be a disadvantage in applications where efficient heat transfer is crucial, such as in heat exchangers or cooling systems. Thirdly, aluminum is prone to corrosion. Although it has a natural oxide layer that provides some protection, it can still corrode in certain environments, especially in the presence of moisture or acidic substances. This limits its use in applications where corrosion resistance is vital, such as marine or chemical industries. Additionally, aluminum is a relatively expensive material compared to other options. Its production and extraction processes require significant energy and resources, contributing to higher costs. Therefore, it may not be the most cost-effective choice for some applications. Lastly, aluminum has limited compatibility with certain substances. It can react with certain chemicals, resulting in degradation or contamination. Therefore, it may not be suitable for applications where it will come into contact with substances that can cause adverse reactions. Overall, while aluminum sheet has numerous advantages such as its lightweight nature, good electrical conductivity, and ease of fabrication, it is important to consider its limitations when selecting it for specific applications.

- Q: How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- The surface roughness of an aluminum sheet directly affects the adhesion of coatings. A rough surface provides more contact points and a larger surface area for the coating to adhere to, resulting in better adhesion. Conversely, a smooth surface offers fewer contact points, making it more difficult for the coating to adhere properly. Therefore, increasing the surface roughness of aluminum sheets can significantly improve the adhesion of coatings.

- Q: Can aluminum sheets be used for packaging?

- Yes, aluminum sheets can be used for packaging due to their lightweight, corrosion-resistant, and recyclable properties.

- Q: Can aluminum sheet be used for heat sinks?

- Yes, aluminum sheet can be used for heat sinks. Aluminum is a common material used for heat sinks due to its excellent thermal conductivity properties. It is lightweight, affordable, and has good corrosion resistance. Aluminum sheet can be easily fabricated into various shapes and sizes, making it suitable for different heat sink designs. The flat and thin nature of aluminum sheet allows for efficient heat dissipation by increasing the surface area available for heat transfer. Additionally, aluminum can be easily machined or extruded to create fins, which further enhance the heat dissipation capability of the heat sink. Overall, aluminum sheet is a popular choice for heat sinks in various applications, including electronics, computers, LED lights, and automotive components.

- Q: Can aluminum sheets be used together with other materials, specifically insulation materials?

- <p>Yes, aluminum sheets can be used in combination with other materials, including insulation materials. Aluminum is often used as a cladding material due to its durability and resistance to corrosion. When combined with insulation materials, it can enhance the thermal performance of a structure by reducing heat transfer. This combination is common in construction and roofing applications, where aluminum sheets can provide a protective outer layer while the insulation material manages thermal control. The use of aluminum with insulation materials can lead to energy-efficient buildings and improved indoor comfort.</p>

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q: Which is better aluminum or stainless steel?

- They each have their own advantages and disadvantages. Which one is better depends entirely on what you're USING it for! -Aluminum has a better strength to weight ratio. In other words, while it is not as strong as steel, the fact that it weighs less than half as much makes up for it's lower strength. This is why most airplanes are made of aluminum. -Aluminum is generally more corrosion resistant than all but the most expensive stainless steels. However under certain condition it may corrode rapidly with catastrophic results. -Al is usually less expensive than stainless steel (SS), Though it is 2-4 times more expensive than ordinary (non-stainless) steels. -Al is fairly soft and easier to cut, saw, carve, drill, and machine than steels. (SS is very difficult to work with due to it's excellent abrasion resistance.) -Al is an excellent conductor of heat. This is why it's used for car radiators and air conditioning units, and for pots and pans. -Al is a very good conductor of electricity. Because of it's high conductance, light weight, and corrosion resistance, Al is used for high-voltage overhead power lines. -Stainless steel is stronger than Al, if weight is not a consideration. (In this respect, since Al is weaker, a pipe that could handle the same water pressure would need to be thicker if it was made of Al, So in many cases you can save money on materials by using SS) -SS is easy to weld. (welding Al is very difficult.) -SS can be used at much higher temps. than Al; which becomes very soft above about 400 degrees. -SS is more impact resistant than Al, in other words, it is more ductile. -SS is much more resistant to wear and abrasion, which as I said before makes it difficult to work with.

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- Yes, it can, throw it away, aluminium in deodorant can also cause breast cancer, so use one that is aluminium free

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets are known for their excellent creep resistance. Creep is the tendency of a material to slowly deform under a constant load over time. Compared to other metals, such as steel, aluminum has a relatively low creep rate, meaning it deforms at a slower rate under the same load and temperature conditions. This makes aluminum sheets suitable for applications requiring dimensional stability and resistance to long-term deformation. Additionally, aluminum's low creep resistance allows it to withstand high temperatures without significant deformation, making it suitable for use in various industries, including aerospace, automotive, and construction. However, it is important to note that the creep resistance of aluminum sheets can vary depending on the alloy used, heat treatment, and other factors, so it is essential to choose the appropriate aluminum alloy and design for specific applications to optimize creep resistance.

- Q: Can 101 aluminum sheets be polished to a mirror-like finish?

- A mirror-like finish can be achieved on 101 aluminum sheets. Aluminum, being a lightweight and highly malleable metal, can be easily polished to obtain a reflective surface. Nevertheless, achieving a mirror-like finish on aluminum requires several steps and the use of appropriate polishing techniques and materials. To achieve a mirror-like finish on aluminum sheets, it is customary to begin by thoroughly cleaning the surface to eliminate any dirt, debris, or oxidation. Following that, sanding the surface with progressively finer sandpaper grits is necessary to eliminate imperfections or scratches. This step is vital in order to create a smooth and uniform surface that can be polished to a high level of shine. Once the sanding is completed, the polishing stage comes into play. There are various methods and materials available for polishing aluminum, such as abrasive compounds, buffing wheels, and polishing pads. These tools are utilized to exert pressure and friction on the aluminum surface, effectively removing any remaining scratches or imperfections and resulting in a smooth, reflective finish. Ultimately, to achieve a genuine mirror-like finish, the process of buffing or burnishing is often employed. This entails applying a polishing compound to the aluminum surface using a soft cloth or a specialized buffing wheel. The compound further refines the surface and enhances its reflective properties, ultimately leading to a mirror-like finish. It is important to note that achieving a mirror-like finish on aluminum can be a time-consuming and labor-intensive process, particularly when dealing with a large quantity of sheets like 101. Additionally, the quality of the aluminum sheets themselves and the skill level of the individual performing the polishing can also impact the final outcome. Nevertheless, with the right materials, techniques, and patience, it is indeed possible to polish 101 aluminum sheets to a mirror-like finish.

Send your message to us

Hindalco Aluminum Roofing Sheets - EN AW-5083 Aluminium Panel for Oil Tanker Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords