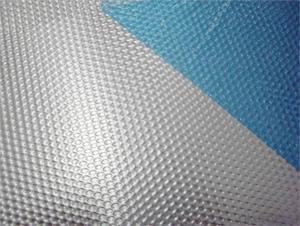

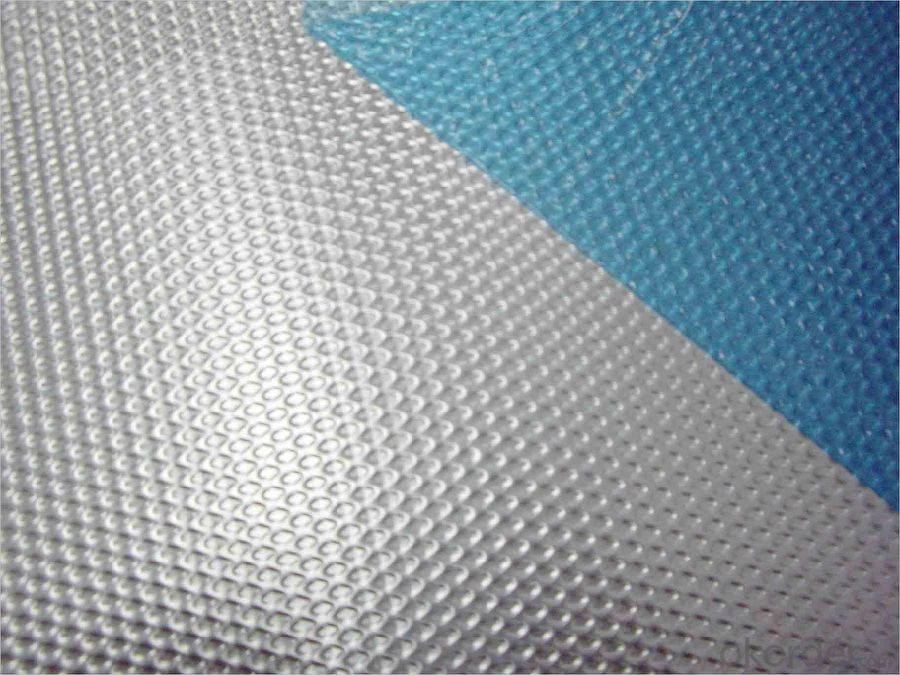

Embossed Aluminum Decking Sheets Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Stucco Embossed Coated Aluminium Coil

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-1.50mm |

Width: | 10mm- 1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2 Usage/Applications of Aluminum Can Stock(Body)

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

3 Packaging & Delivery of Coated Aluminium Coil/Sheet

Packaging: Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Aluminum sheets have multiple uses in decoration and architecture. This versatile material can be easily shaped and molded into various forms, making it perfect for a wide range of architectural projects. It is commonly utilized in exterior cladding, roofing, window frames, and facades, lending a sleek and contemporary appearance to buildings. Moreover, aluminum sheets are also employed for decorative purposes like wall panels, art installations, signage, and furniture. Architects and designers often choose aluminum due to its lightweight and durable properties, enabling them to create visually appealing and functional structures. Additionally, aluminum's resistance to corrosion makes it suitable for both indoor and outdoor applications.

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Yes, aluminum sheets are suitable for furniture manufacturing. Aluminum is a lightweight and versatile material that offers numerous advantages for furniture production. It is corrosion-resistant, making it ideal for both indoor and outdoor furniture. Additionally, aluminum has a high strength-to-weight ratio, allowing for the creation of sturdy and durable furniture pieces. It is also easy to work with, as it can be cut, bent, and welded into various shapes and designs. Moreover, aluminum can be finished with different coatings or paints to enhance its appearance and protect it from wear and tear. Overall, aluminum sheets are a viable option for furniture manufacturing due to their strength, versatility, and aesthetic appeal.

- Q: Which kind of material does aluminum sheet(aluminum oxide) belong to?

- hardware

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Aluminum extruded radiator:It is widely used in modern material with good heat dissipation cooling industry, most of them use 6063 T5 high quality aluminum, its purity can reach above 98%, the heat conduction ability, low density, low price so get the favor of the major manufacturers.

- Q: Are aluminum sheets suitable for reflective signage?

- Indeed, reflective signage can effectively utilize aluminum sheets. This adaptable material is frequently employed for such signs because of its resilience, lightness, and capacity to reflect light. With a noteworthy reflectivity index, aluminum proves itself ideal for situations where visibility is of utmost importance, such as road signs, traffic signs, and safety signs. By applying reflective films or paints to aluminum sheets, their reflective properties can be further enhanced, guaranteeing optimal visibility even in dimly lit environments. Furthermore, aluminum's resistance to weathering, corrosion, and fading ensures that it remains a durable and economical option for reflective signage in the long run.

- Q: We just bought a house with aluminum wiring and we knew about it in the inspection report, but everyone kept telling us it's no big deal. There was so much going on and I didn't look into it myself and now I just surfed the web on it and I am filled with anxiety! Please help! Did we make a huge mistake? How common are the dangers? Also, my insurance company didn't ask me about wiring, but some sites said that they don't cover aluminum wiring. Should I ask them? I am so overwhelmed and scared. I do not want a fire for my family!

- All of these answers are good. There is a concern. I would suggest that if there is a question of security -- that you slip ( or get an electrician) to slip each switch and outlet out of the wiring box and tighten the connections. As for the racoons, there are simple and pretty much low cost (under 30 bucks, voltage sensors at your local electrical supply, and maybe at Home-Depot. These really nice devices sense the presence of AC electricity in the wall, even locating the actual point where the electricity stops at a break! This is a do-it=yourself project.

- Q: Can aluminum sheets be used for insulation jackets?

- Indeed, insulation jackets can indeed employ aluminum sheets. Aluminum possesses exceptional thermal conductivity characteristics, enabling it to proficiently deflect heat and hinder the transmission of thermal energy. Consequently, it becomes the perfect substance for insulation jackets, as it aids in preserving temperature regulation and reducing heat loss or gain. Furthermore, aluminum sheets are lightweight, long-lasting, and impervious to corrosion, rendering them a pragmatic option for insulation applications.

- Q: I am doing some exam review and do not know how to do these...Calculate the number of Nitrate ions in 3.99 g or aluminum nitrate.

- ? number of NO3 = 3.99g AlNO3 x(1mol AlNO3/212.996 g AlNO3)x(1mol NO3/1mol AlNO3)x(6.02*10^23 number of NO3/1mol NO3)=11*10^21 number of NO3

- Q: I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- Aluminum Vs Fiberglass Ladder

Send your message to us

Embossed Aluminum Decking Sheets Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords