Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

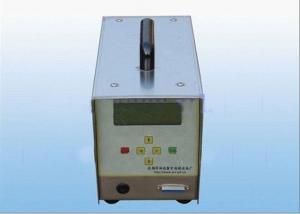

Electrofusion Welding Machine

1. type: electrofusion welding machine

2.welding range : 20~315mm

3. input power: 220V 50HZ

♦ Our eletrofusion welding machine adopt RMS control, main suitable for connection of PE pipes and fittings which are used for natural gas or water supply. It is the perfect equipment for manufacturers or construction units of pipes and fittings.

♦ High brightness LCD display. Chinese/English operation. Friendly interface for human and machine

♦ Wide power supply and voltage input, fully suitable for spot electric network wave

♦ High accurate power , time controlling. Ensure welding quality

♦Huge storage capacity for welding datum, easy way to enter welding parameters

♦ compact design, small volume and light weight

Dimension |

L×W×H(mm) |

330×200×270 |

Input data |

Input voltage |

48V±10%,220V±20% or 380V±20% |

Input power |

40~65Hz | |

Output data |

Output voltage |

0~50V |

Output power |

3.5KW | |

Main

Control

Specification

|

Environment temperature |

-15°C~45°C |

Storage temperature |

-30°C~70°C | |

Control ways |

Constant voltage/currency/power | |

Data record times |

500 | |

Power constant precision |

≤±0.5% | |

Overload capacity |

1.5Ie,1 minute | |

Time control precision |

≤±0.01% | |

Temperature measurement precision |

±0.5°C | |

Duty rates |

60% | |

Data output |

RS232 | |

protection |

See the fault sheet | |

Soft operation |

Windows 2000/XP |

- Q: Can the coil in the welder be connected to the joint? Does this affect the power of the welding machine?

- Yes, please. Just keep in touch

- Q: What's the butt welding machine? What's the difference between it and welding?

- Butt welding machine is flash butt welding machine. In construction, the welding of column reinforcement is useful. Flash butt welding machine using the instantaneous current arc ignition flux to produce high temperature melting steel joint, by pressurizing the two steel welded together.

- Q: Do welding electrodes need to be used for the welding machine? Will there be smoke and dust in the welding process?

- Butt welding machine is also called impact welding machine, the welding machine voltage is very low, the current is very large, the use of two pieces of metal collision, short circuit, high current welding. Soot is not large, but there is an arc of shallow metal dust.

- Q: I would like to buy a flash butt welding machine, I would like to understand the principle of welding machine to see if it can meet the requirements of welding. I welded the cross section of the pipe cross section, requiring the sealing 15KG pressure of the bead

- The working principle of flash butt welding machine: butt welding of the workpiece, the gas control, first slowly push the workpiece welding oxidation and bumps flash surface after removing hot workpiece face welding plastics, then quickly add a forging force to two penetration welding welding end.A microcomputer controller is used to control the clamping, flashing, upsetting, holding, stopping and the whole welding process, and the control accuracy is high.The product of high welding strength, good compactness, no weld, no slag, firm and beautiful.Widely used in carbon steel, alloy steel, nonferrous metal pipes, bars, plates, profiles between the butt welding or dissimilar metal butt welding.

- Q: I am in urgent need of welding machines, welding machines and electrodes. Does anyone know where to sell them?

- I am the manufacturer of welding rod, the price is relatively low. Electric welder, etc., can help you get a piece of goods, relatively cheap, how much you call?

- Q: Want to do one, but know this knowledge wins, want to know a friend pointing in one or two, thanks in advance! QQ:237411214Have a full set of spare parts can provide the circuit?I want to 2mm thick iron sheet and diameter of about 6mm wire butt, because the product shape is special, outside buy not applicable, so just want to do it yourself.

- It's not easy to do it yourselfThere are many kinds of light fittingsIt's not always easy to make it out

- Q: How to use PE electric melting machine PE electric welding machine

- 1. before the operation, the electric melting pipe and the pipe are installed and butt welded. The output plug of the welding machine is inserted into the electric melting pipe machine.2. power on display in the main menu press the down arrow keys can select a function of the machine, and then press the confirm button to enter the sub menu.(1) the parameter setting function, in the main menu, select settings (the color display), confirmed by the enter parameter set up menu, you can set the welding parameters. Press the down arrow keys to select one of the parameter settings, according to a key to select a key, press the +, to modify a cursor blinking. The welding time is in seconds, and the cooling time is divided into units. Print function by + number, the display is yes, open the print function, then, in the welding process, the printer every 5 seconds, print a welding parameter, press the number to close the print function.(2) the welding operation, in the right setting of the machine parameters, welding operation on the pipe, which is the fifth option in the main menu, namely "run", the machine setting parameters, after confirmation, press the start button, the machine start welding operation.(3) when welding normally, the machine starts counting from the preset time, and when the display is 0000, the machine will alarm when the welding is finished. At this point, press the one button, the machine automatically into the cooling state, after cooling, the machine also alarm. Press this one key to end the alarm and return to the main menu.(4) when one of the faults occurs, the machine will stop automatically and display error messages. The current error, check the output plug and tube connection is good; the voltage error, check whether the power supply voltage exceeds the 175250V range; temperature error, check the temperature sensor is disconnected.(5) to carry out second welding, repeat the above process only.

- Q: The structure and working principle of each component inside the best can talk about, I am 22, only contact with the industry, only to learn more to ask, at present only mastered the knowledge of physics in high school, so I do not understand too deep. Thank you!I graduated from University, and now with the construction machinery sold at home, but just beginning to contact this line, a little fuzzy. On the first floor, what you are talking about is not a machine! I know it's called flash butt welding machine. For example, 100150... There are two things that produce a breakdown current. When they are short circuited, it seems that an arc is produced, and then the iron is melted. Do you understand? Don't be so complicated. I just want to make sure every component is clear. I don't repair the machine

- If you are alone here to ask you what is a principle, the wizards. Personal view: you don't have to make the construction and work of each component clear, because even the producer can't do it. In fact, you might as well work hard at the operation, or do some work in the maintenance or in the welding equipment. This may lead to more.

- Q: UN1-125 type butt welding machine working principle, who knows, I encountered the problem is welding power, but can not work, who can give I I answer?

- Now domestic welding machine number is quite confusing. First of all, would you like to tell me whether it's pneumatic or manual?. Separately, it is simply that the machine uses no compressed air as the source of air.Then, the problem you describe is relatively simple, and the welder doesn't work on power. What you mean by "electrify" means that the control box has electricity or other display power is on. Or is there a connection between the two electrodes, and there is no electricity through the work room? You can explain it in detail so that I can explain it to you.

- Q: How to choose welding leakage current

- First calculate what your total power is, then select the leakage switch according to the power.The power / voltage is equal to the current. For example, the total power 4KW, then 4000/220=18A.The rated current of the leakage switch is greater than the load current.In general, the total leakage switch is selected by 1.5 times the load current, 18A*1.5=27A.There is no leakage switch for 27A, soThe leakage switch should select 32A.The leakage current is selected by 30MA.

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | |

| Main Markets | 40.00% Domestic Market 15.00% Mid East 10.00% South Asia 10.00% Southeast Asia 10.00% South America 5.00% Eastern Asia 5.00% Africa 5.00% North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Russian, Korean |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords