Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

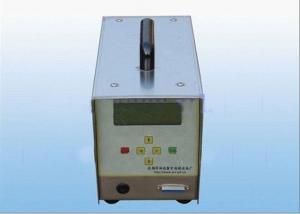

Electrofusion Welding Machine

1.automatically changed and stored

2.universal fusion resistor, barcode and manual

3.check by Korea gas safety corporation

Universal electro fusion processor

Electro Fusion Fitting system is electrically fusion jointing method that the gap between fitting and PE pipe is heated and melted by the means of resistance wires which are placed in the socket in the fitting. Each EF Sockets are controlled automatically by micro-processor and RMS value.

Features

All functions are designed for ease of operation.

The display is equipped with back-lighting. This will enable operator to work in poor lighting and at night

Depending on site, fusion number is automatically changed and stored (up to 10 site names). Inputting site name can continuously connect fusion number and perform work even when moving from site to site.

You can see fusion content using view function without printing. (Black mark at abnormal part)

The built-in printer uses thermal paper (safe for 5 years). Outputting 1 fusion result takes about 1.5 seconds.

Change quantity of output current per hour is divided into 10 sections for output, so that reliability on fused material may be enhanced.

Output capacity is designed as 3600W (@220Vac) in order to supply stable output.

The machine is equipped with a bar code reader of convenient CCD type, which can read at once.

Stable fusion becomes possible thru accurate control of output voltage (8-50±0.2Vac) at the input voltage even with high voltage jumps.

Specification

Operating voltage |

AC86 to 264V |

Fusion voltage |

AC170 to 250V |

Output voltage |

AC8 to 50V ±0.2V |

Operating Temperature |

-23°C to 49°C |

Dimension |

380(W)X320(D)X270(H) |

Weight |

21Kg |

Power consumed |

0.1Kw~3.6Kw |

Output current |

2A~80A |

Fusion data storage |

200 Times |

Fusion time |

10sec to 5999sec |

- Q:How long does it take for electroslag welding machine to butt a steel joint? Which kind of butt welding method is adopted for steel butt joint on construction site? Which welding machine is the best?

- Electroslag pressure welding is only used for vertical or small angle steel butt joint, the diameter of reinforcement is 12~20mm. The vertical reinforcement of the column longitudinal reinforcement and shear walls is used on the site. Electroslag pressure welding is a portable, moving and flexible device. The welding speed is fast, and each joint is completed in about ten minutes.

- Q:What is the power of the welding machine used on the site, kW?

- Which one is the same?.

- Q:Leakage switch operating current 30mA can not meet the use of steel butt welder, how should I do?

- Switch to a 60 or larger leak switch, or else it won't start

- Q:What is commonly used in welding excavator bucket machine good

- Most of the manufacture now uses carbon dioxide gas protection! Repair, then the general electrode arc welding enough!

- Q:KW how many UN1-100 pairs of welding machines?

- UN1-100 type butt welding machine is about 30KW.Specific parameters are as follows:The project | machine model UN1-125ARated capacity (KVA) 125Primary voltage (V) 380Primary no-load voltage (V) 4.06-8.04Maximum welding diameter (mm) 32Rated load duration (%) 20Maximum tension (kg/mm2) 50Number of welds per hour (times /h) 20-30

- Q:The structure and working principle of each component inside the best can talk about, I am 22, only contact with the industry, only to learn more to ask, at present only mastered the knowledge of physics in high school, so I do not understand too deep. Thank you!I graduated from University, and now with the construction machinery sold at home, but just beginning to contact this line, a little fuzzy. On the first floor, what you are talking about is not a machine! I know it's called flash butt welding machine. For example, 100150... There are two things that produce a breakdown current. When they are short circuited, it seems that an arc is produced, and then the iron is melted. Do you understand? Don't be so complicated. I just want to make sure every component is clear. I don't repair the machine

- UN butt welding machine is a series of resistance welding machines! The normal output no-load voltage is 3-8V, which is the working principle of high current generated by low voltage, welding the reinforcement! The welding machine often appears the breakdown is the contact is not good, but the welding is not firm. You can sell it with our universal butt welder in Shanghai, all copper! The failure rate is very low!

- Q:How much is the power consumption of 100 thousand volt ampere welder?

- That is, the capacity of the welder.Only when the welding power consumption, specifically depends on the length of time welding. Generally only a dozen degrees of electricity

- Q:What is the reason that the welding band saw blade is not firmly used after two years of flash butt welding machine? How to solve?

- Check the electrode face of the welder. There is something wrong with it.

- Q:Want to do one, but know this knowledge wins, want to know a friend pointing in one or two, thanks in advance! QQ:237411214Have a full set of spare parts can provide the circuit?I want to 2mm thick iron sheet and diameter of about 6mm wire butt, because the product shape is special, outside buy not applicable, so just want to do it yourself.

- It's not easy to do it yourselfThere are many kinds of light fittingsIt's not always easy to make it out

- Q:What's the biggest difference between domestic and imported steel cord welder? Besides price?

- Different quality,Central Wei import, professionalMiddle and South import, one-stop solution. One stop supply chain logistics trade expert!

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | 20.00% Western Europe 20.00% Mid East 20.00% South America 20.00% North America 10.00% Northern Europe 9.00% Southeast Asia 1.00% Central America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords