Eco-friendly Waterproof Indoor WPC Floor Decking / Engineered Flooring

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Waterproof Indoor WPC Floor Decking / Engineered Flooring

一.Product Description:

Eco-friendly Waterproof Indoor WPC Floor Decking / Engineered Flooring

High Quality Supplier Looking For Partner

35% HDPE (Grade A Recycled HDPE),

55% wood fiber (Professionally treated dry wood fiber),

10% chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants...etc.).

Features

1.Looks and feels like nature wood

2. Waterproof, Mildew-resistant

3.Anti-High degree of UV and colour stability

4. No hazardous chemicals,100% recycle,Environmental friendly,Saving forest resources

5.weather resistant,Suitable from -40'C to 60'C

6. Easy to install and clean

7. Unaffected by termites and other insects, rodents,worms or marine parasites

8. Low maintenance cost

9. Anti-slip, less cracking, less warping

High Quality Supplier Looking For Partner

35% HDPE (Grade A Recycled HDPE),

55% wood fiber (Professionally treated dry wood fiber),

10% chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants...etc.).

Features

1.Looks and feels like nature wood

2. Waterproof, Mildew-resistant

3.Anti-High degree of UV and colour stability

4. No hazardous chemicals,100% recycle,Environmental friendly,Saving forest resources

5.weather resistant,Suitable from -40'C to 60'C

6. Easy to install and clean

7. Unaffected by termites and other insects, rodents,worms or marine parasites

8. Low maintenance cost

9. Anti-slip, less cracking, less warping

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

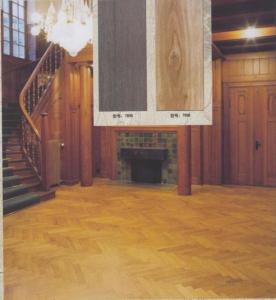

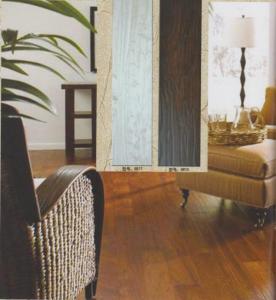

四. More picture for your reference

- Q: How do I show this if I do not know anything about floor(x)?

- floor(x) is x rounded down to the next integer. So floor(8.3) = 8, floor(-4.6) = -5, floor(11) = 11. Let x = d + r, where d is an integer and r is a decimal with 0 <= r < 1. floor(5*x) = floor(5d + 5r) = 5d + floor(5r) <= 5d + 4 = 4 + 5*floor(d) <= 4 + 5*floor(x). EDIT I had a typo above when defining d and r, it is now correct.

- Q: floor hockey

- can't you just call it stickhandling like we do in icehockey?

- Q: Ive been researching earthen floors. Im a little confused. Does this floor serve as the foundation as well as the floor or is it just an alternative to carpet and such?

- A foundation is used to hold up walls and a roof. I`m sure you do not want the roof to fall upon you. A normal foundation used is concrete. Check with your local building department on what is required for foundations.

- Q: it says its floor G/A, but there are rows at the honda center so i dont get itits for blink 182 by the way

- Floor seats at the honda center are those on the main floor. The are going to be the ones closest to the stage.

- Q: I am putting floating laminate floors in my kitchen. Do I run them under the cabinet toe kicks or up to the and then run a bead of caulk?

- Dave C has it exactly right. Remove the toe kick, install floor leaving 1/4 gap, rip toe kick, reinstall toe kick with the factory cut to the floor.

- Q: i just moved into a home that has parquet floor through the house but is covered by carpet in almost all rooms i want to know how much it cost to fix up the floor after removing the carpet, i already heard its a whole lot of work

- Most of your parquet flooring is only a 3/8 ths and 1/2 thick and is a laminated product and can t be sanded down a lot. It would depend also if the flooring is a wax or a urethane finish.. You may have to call in a flooring person to get a look at it and determine exectly what you need to do.. It may be as simple as re waxing it.. Any questions you can e mail me through my avatar.. GL

- Q: The previous owner of my house painted the cement slab garage floor. Now the paint is peeling off and looks bad. I would like to seal the floor with an epoxy-based sealant. Can I seal over top of the paint, or do I need to have the paint sandblasted off first?

- They make some really good floor paints. If I were you I would clean any loose paint off the floor clean it real well with a solvent to remove any oils and then wash with a good detergent. Rinse really well to remove any residue. Then when you repaint it with a floor finish it will act as a sealer and look really good. To remove all the paint with sand blasting would probably hurt the finish on the concrete and not look very good. This is the process I would use. I have painted many garage floors. I worked in a complex with one hundred and sixteen units all with painted floors. Good luck

- Q: Before the exchange of space to see when people see the floor with a very nice wall, do not know how to do it. With the glue also rafting to destroy the more slander scraper Xi Shan is to do keel? Do you know? More

- The process is: the first to remove the wooden floor, choose a good clean pile up the spare wall covered with a layer of plastic film (casually stick on the line) and then in the vertical direction of the wall every thirty centimeters nailed a wooden (You can buy 10MM thick wood line, I use the shirt wood, direct hit the drill drill, stuffed into 8MM rubber particles, and then knock into the nail, but also every 30-50CM nail) <raft The floor of the floor from the top to the top, the mouth of the mouth, in the wood on the mouth of the ramp at the F25 air gun nail, basically and the same as the floor to the top of the top directly on the floor side of the top edge of the nail Line modification

- Q: Plastic floor self-leveling ground need to make cement mortar leveling ahead of time

- Finished self-leveling itself on the basic level, but to see how the ground foundation, anti-anti-sand, harm the field out of the infiltration of aldehyde over the anti-sand, then self-leveling to do thick, or not a few years are plastic opened

- Q: Can radiant floor heating be installed in the concrete pour, then after concrete has sufficiently cured (28 days) can a resinous coating, such as a epoxy/polyurethane floor coating be installed on a floor that will later be radiant heated. My concern is that these coatings are very moisture intolerant. Does radiant floor products, create any moisture in the slab that could rise to the surface. Does changes in temps affect the moisture levels in concrete. Electric radiant floor products seem to be best.Pipes filled with hot water to me is a concern. Do the pipes &quot;sweat&quot; causing condensation or are they wrapped. I am currently on a large project and these questions are coming up in the design forum.

- RADIANT FLOOR HEAT WITH WATER IS THE MOST EFFICIENT WAY TO HEAT A FLOOR. IT DOSE NOT SWEAT. WE HAVE A 9000 SQ. FT. SHOP ALL IN FLOOR HEAT WITH A GEO THERMAL HEAT/ COOLING. PAYBACK ON THE EXTRA COST OF GEO THERMAL IS 7 YEARS. ALL OUR FLOORS ARE EPOXY SEALED.

Send your message to us

Eco-friendly Waterproof Indoor WPC Floor Decking / Engineered Flooring

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords