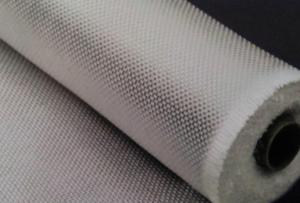

E-glass Fiberglass Woven Roving,400g,1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

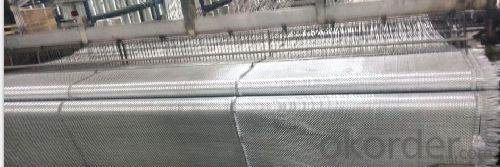

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q:Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. Fiberglass mat tissue is a lightweight material that is commonly used for sound absorption and insulation purposes. It has excellent sound-absorbing properties and can effectively reduce noise levels in various applications, including acoustic panels. It is often used as the core material in acoustic panels to enhance their sound-absorbing capabilities. Additionally, fiberglass mat tissue is easy to work with, making it a popular choice for DIY acoustic panel projects. However, it is important to note that the effectiveness of acoustic panels also depends on other factors such as panel design, thickness, density, and installation method. Therefore, it is recommended to consult with experts or conduct thorough research to ensure that fiberglass mat tissue is the appropriate material for your specific acoustic panel needs.

- Q:Can fiberglass mat tissue be used for automotive repairs?

- Yes, fiberglass mat tissue can be used for automotive repairs. It is commonly used for reinforcing and repairing various parts of a vehicle, such as body panels, bumpers, and interior components. The fiberglass mat tissue provides strength, durability, and flexibility, making it an ideal material for automotive repairs.

- Q:Are there any environmental considerations when using fiberglass mat tissue?

- Yes, there are several environmental considerations when using fiberglass mat tissue. Firstly, the production of fiberglass mat tissue involves the extraction and processing of raw materials, which can have a negative impact on ecosystems and contribute to air and water pollution. Additionally, fiberglass mat tissue is not biodegradable and can contribute to landfill waste if not properly disposed of. Furthermore, the manufacturing process of fiberglass mat tissue usually requires significant energy consumption, which can contribute to greenhouse gas emissions and climate change. Therefore, it is important to consider and implement sustainable practices when using fiberglass mat tissue to minimize its environmental impact.

- Q:Is fiberglass mat tissue suitable for outdoor applications?

- Yes, fiberglass mat tissue is suitable for outdoor applications. Fiberglass mat tissue is made from woven fiberglass strands that are held together with a binder. This material is highly resistant to water, weather, and UV radiation, making it ideal for use in outdoor environments. It can be used in various outdoor applications such as roofing, insulation, and construction. The waterproof and weatherproof properties of fiberglass mat tissue ensure its durability and longevity when exposed to the elements. Additionally, it is lightweight and easy to handle, making it a versatile choice for outdoor projects.

- Q:Can fiberglass mat tissue be used for insulation in commercial buildings?

- Yes, fiberglass mat tissue can be used for insulation in commercial buildings. It is a common and effective insulation material that provides thermal insulation, soundproofing, and fire resistance properties. It is often used in commercial buildings to improve energy efficiency and create a comfortable indoor environment.

- Q:Can fiberglass mat tissue be used for insulating metal roofs?

- Indeed, insulating metal roofs is possible with the utilization of fiberglass mat tissue. The thermal properties and durability of fiberglass make it a favored selection for roof insulation. By obstructing heat transfer, it aids in maintaining a cooler interior during scorching weather and a warmer one during chilly weather. Moreover, fiberglass is lightweight and straightforward to install, rendering it a pragmatic choice for metal roofs. Generally, the fiberglass mat tissue is positioned between the metal roof panels and the building's interior, furnishing an efficient insulation layer.

- Q:Does fiberglass mat tissue require any special handling or storage requirements?

- Yes, fiberglass mat tissue does require special handling and storage requirements. It should be stored in a dry, clean, and well-ventilated area to prevent moisture absorption. It should also be kept away from direct sunlight and extreme temperatures to maintain its quality. Additionally, it is important to handle fiberglass mat tissue with care to avoid any damage or injury, as it can be sharp and fragile.

- Q:Does fiberglass mat tissue provide any acoustic insulation?

- Fiberglass mat tissue does provide some degree of acoustic insulation. Due to its fibrous structure, it can absorb sound waves and reduce their transmission through walls or other surfaces. However, it is important to note that the level of acoustic insulation provided by fiberglass mat tissue may vary depending on various factors such as thickness, density, and the specific application. In some cases, additional layers or thicker materials may be required to achieve optimal acoustic insulation.

- Q:How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue demonstrates excellent resistance to both mold and mildew. The material is inherently moisture-resistant, which prevents the growth of mold and mildew. Additionally, fiberglass is non-porous and does not provide a suitable environment for these microorganisms to thrive. Furthermore, fiberglass mat tissue is often used in applications where moisture is present, such as in bathroom walls or showers, and it has proven to be highly effective in preventing the growth of mold and mildew. Overall, fiberglass mat tissue performs exceptionally well in terms of mold and mildew resistance, making it a reliable choice for applications where these concerns are prevalent.

- Q:Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Woven Roving,400g,1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords