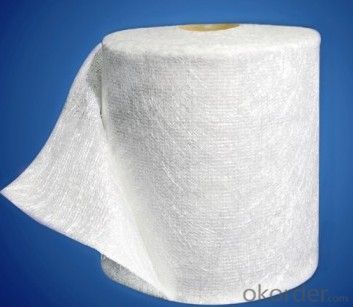

Fiberglass Mat Tissue E Glass Fiber Stitched Chopped Strand Mat for Tube Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction E-Glass Stitched Chopped Mat for tube manufacturing is made by chopping continuous strands into chopped strands and stitching them together. The product has a maximum width of 110 inches. This product can also be used in manufacturing boat.

2.Product Features

Fast breakdown in styrene

Good wet-through and fast wet-out in resins, rapid air lease

3.Product Specifications

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

4.FAQ

Packaging:

E-Glass Stitched Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 275mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper.

Storage:

It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How does the thickness of fiberglass mat tissue affect its flexibility?

- The thickness of fiberglass mat tissue directly affects its flexibility. Generally, thinner fiberglass mat tissue is more flexible compared to thicker ones. This is because the thickness of the mat tissue determines the amount of resin that can be absorbed and the overall weight of the material. Thinner mat tissue allows for more resin saturation, which increases its flexibility. Additionally, thinner mat tissue is lighter in weight, making it easier to bend and shape. On the other hand, thicker mat tissue is less flexible due to its lower resin absorption capacity and heavier weight. It may require more force or effort to bend or shape thicker mat tissue compared to thinner ones. Therefore, the thickness of fiberglass mat tissue plays a crucial role in determining its flexibility.

- Q: How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue boasts exceptional moisture absorption capabilities. Its composition of fine fibers grants it a large surface area, allowing for swift moisture absorption. Moreover, fiberglass mat tissue exhibits hydrophobic properties, repelling water and preventing prolonged moisture retention. This attribute renders it an optimal material for moisture-resistant applications, including the construction of waterproofing membranes or the production of boats and water tanks. In sum, fiberglass mat tissue showcases remarkable performance in averting moisture absorption and upholding its structural integrity, even within damp surroundings.

- Q: How long does fiberglass mat tissue typically last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, its exposure to environmental conditions, and the level of maintenance. On average, fiberglass mat tissue can last anywhere from 20 to 30 years. However, with proper installation and regular upkeep, it is possible for it to last even longer. It is important to note that regular inspection and maintenance can help identify any signs of wear or damage, allowing for timely repairs or replacements to ensure its longevity.

- Q: Is fiberglass mat tissue suitable for insulation in sports facilities?

- Yes, fiberglass mat tissue is suitable for insulation in sports facilities. It is a commonly used material for insulation due to its excellent thermal insulation properties, durability, and resistance to moisture. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a practical choice for sports facilities where energy efficiency and temperature control are important factors.

- Q: Does fiberglass mat tissue require any special precautions during transportation?

- Special precautions must be taken during the transportation of fiberglass mat tissue as it is a delicate material that can easily be damaged if not handled correctly. To ensure safe transportation, several measures should be implemented. To begin with, it is necessary to pack the fiberglass mat tissue in a strong and durable material that can protect it from external impacts and vibrations. Heavy-duty cardboard boxes or wooden crates should be used to provide sufficient cushioning and support. Furthermore, it is vital to clearly label the packaging as "Fragile" or "Handle with Care" to alert handlers about the delicate nature of the product. This will help prevent any mishandling or rough treatment during transportation. In addition, the fiberglass mat tissue should be stored and transported in an upright position to minimize the risk of bending or folding that could potentially damage the material. It is also important to avoid placing heavy objects on top of the fiberglass mat tissue to prevent unnecessary pressure or crushing. Lastly, it is advisable to utilize secure and reliable transportation services with experience in handling delicate materials like fiberglass mat tissue. This ensures that the product is transported with the utmost care and attention, reducing the likelihood of damage during transit. By adhering to these special precautions, the risk of damage to the fiberglass mat tissue during transportation can be significantly reduced, guaranteeing its arrival in perfect condition.

- Q: Does fiberglass mat tissue require any special precautions during disposal?

- Special precautions are necessary when disposing of fiberglass mat tissue. The composition of fiberglass mat tissue can result in the release of fine particles and fibers into the air if it is handled or broken. These particles and fibers can be harmful if they are inhaled or come into contact with the skin and eyes. Therefore, it is important to take certain precautions when disposing of fiberglass mat tissue. To begin with, it is advisable to wear suitable personal protective equipment (PPE) such as gloves, goggles, and a respirator mask in order to minimize the risk of exposure. This will help to prevent the inhalation of airborne particles and fibers, as well as protect the skin and eyes from any potential irritation. Additionally, fiberglass mat tissue should be placed in sealed bags or containers during disposal to prevent loose fibers from becoming airborne during transportation. It is also recommended to label these bags or containers as "hazardous" or "fiberglass waste" so that others are aware of the potential risks involved. Furthermore, it is vital to adhere to local regulations and guidelines for the disposal of fiberglass mat tissue. Depending on the specific location, there may be specific requirements for handling and disposing of hazardous waste materials, including fiberglass. These regulations exist to safeguard public health and the environment. In conclusion, special precautions are necessary when disposing of fiberglass mat tissue in order to minimize the risk of exposure to harmful particles and fibers. Wearing appropriate protective equipment, using sealed containers, and following local regulations are all crucial steps to ensure safe disposal practices.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Indeed, fiberglass mat tissue proves to be a valuable asset when it comes to restoring fiberglass jet skis. This material is frequently employed in fiberglass repairs due to its ability to fortify and reinforce afflicted regions. Its versatility allows for its use in a multitude of fiberglass repair scenarios, such as rectifying cracks or punctures found in jet skis. When skillfully applied, fiberglass mat tissue effectively reestablishes the jet ski's structural soundness, guaranteeing a resilient and enduring mending.

- Q: Can fiberglass mat tissue be used in wet environments?

- Indeed, wet environments can indeed accommodate the utilization of fiberglass mat tissue. This specialized material has been ingeniously engineered to possess an inherent resistance to moisture, thereby enabling it to endure prolonged exposure to water. Consequently, this remarkable attribute renders it highly suitable for deployment in various sectors, most notably construction, marine, and automotive industries. These particular domains frequently necessitate the deployment of components or structures that inevitably encounter water, humidity, or moisture. The material's unparalleled resistance to water impeccably guarantees the preservation of its structural robustness and ensures that it remains impervious to degradation or any diminishment in its performance properties even when confronted with damp conditions.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- The typical mechanical properties of fiberglass mat tissue include high tensile strength, stiffness, and dimensional stability. Fiberglass mat tissue is known for its excellent resistance to breakage and deformation under stress, making it suitable for applications that require durability and structural integrity. It also exhibits good impact resistance, allowing it to withstand external forces without significant damage. Additionally, fiberglass mat tissue has a low coefficient of thermal expansion, meaning it is less prone to expanding or contracting with temperature changes, resulting in improved dimensional stability. These properties make fiberglass mat tissue a popular choice in various industries, such as construction, automotive, and aerospace, where strength and reliability are crucial factors.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Yes, fiberglass mat tissue can be used for repairing automotive parts. It is commonly used in automotive repairs as it provides strength and durability to the repaired area. The mat tissue can be applied with resin to reinforce damaged or weakened sections of automotive parts, making it an effective solution for repairing various components.

Send your message to us

Fiberglass Mat Tissue E Glass Fiber Stitched Chopped Strand Mat for Tube Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords