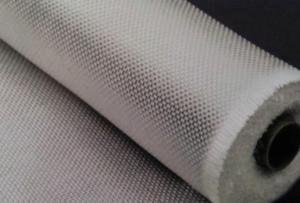

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 500g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Woven Roving

1)Low Fuzz

2)Fast Wet-out&Impregnation

3)Easy Lay-up&Air Release

4)Excellent Mechanical Strength

Main Features of Woven Roving

1.CWR400

2.360-380g/m2

3.77.5px or 2250px width

4.plastic woven bag

Application of Woven Roving

Unit | Product No. | Weight(gsm) | Technique | Moisture content | combustible matter content(%) |

M | EWR260 | 264±13 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR270 | 261±13.5 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR360 | 354±18 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR500 | 504±25 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR580 | 576±29 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR600 | 622±30 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR800 | 850±40 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR200 | 200±15 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR400 | 385±30 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR600 | 600±45 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR800 | 810±40 | Plain | ≤0.15 | 0.40-0.80 |

Images:

FAQ of Woven Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Is fiberglass mat tissue easy to install?

- Installing fiberglass mat tissue is relatively easy. This lightweight and flexible material can be easily cut and shaped to fit any surface. It can be applied using different methods, including spraying, rolling, or brushing on adhesive. Moreover, the tissue is self-adhesive, which simplifies the installation process as it readily adheres to the desired surface. Additionally, fiberglass mat tissues are generally designed to resist water and offer excellent insulation, making them a favored choice for various applications. In conclusion, by adequately preparing and following the manufacturer's guidelines, installing fiberglass mat tissue can be a simple and trouble-free task.

- Q: What is the tear resistance of fiberglass mat tissue?

- The ability of fiberglass mat tissue to withstand tearing or ripping when exposed to mechanical stress or force is referred to as its tear resistance. Due to its strong and durable nature, fiberglass mat tissue is renowned for its high tear resistance. This tear resistance is typically quantified and reported as tear strength, which measures the force needed to tear the material. The determination of tear strength involves standardized testing methods like the Elmendorf tear test or the tongue tear test. Various factors, including thickness, density, and composition, can influence the tear resistance of fiberglass mat tissue. Nevertheless, fiberglass mat tissue generally exhibits outstanding tear resistance properties, making it an excellent choice for applications where durability and strength are crucial, such as in the construction industry for reinforcement materials or in the production of composite materials.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- The thermal conductivity of fiberglass mat tissue is typically low, ranging from 0.03 to 0.06 W/m·K.

- Q: Can fiberglass mat tissue be used for composite tooling?

- Composite tooling can utilize fiberglass mat tissue, a lightweight material formed from randomly arranged strands of fiberglass that are bonded together with a resin binder. This material is commonly employed in composite applications like boat construction, automotive components, and aerospace structures, serving as a reinforcement material. Utilizing fiberglass mat tissue for composite tooling can bring about increased strength and stiffness to the structure of the tooling. By layering and impregnating the mat tissue with resin, a sturdy and long-lasting composite tool can be formed. The resin binder in the mat tissue aids in holding the fibers together and offering resistance against wear and tear. Additionally, fiberglass mat tissue is malleable and easily molded into intricate shapes, making it suitable for crafting tooling with complex designs. It can be effortlessly cut and shaped to match the desired dimensions of the tooling. Nevertheless, it is crucial to acknowledge that fiberglass mat tissue alone might not meet the requirements of all tooling applications. Depending on the specific demands of the tool, additional reinforcement materials like carbon fiber or Kevlar may be necessary to augment strength and durability. To summarize, fiberglass mat tissue presents a cost-effective and practical option for composite tooling, bestowing strength, flexibility, and user-friendliness.

- Q: Does fiberglass mat tissue provide good thermal conductivity?

- No, fiberglass mat tissue does not provide good thermal conductivity. Fiberglass is known for its insulating properties, meaning it is a poor conductor of heat. It has a low thermal conductivity, which means it does not effectively transfer heat. This makes fiberglass mat tissue a suitable material for insulating applications where heat transfer needs to be minimized, such as in building insulation or in the manufacturing of heat-resistant clothing.

- Q: What is the expected lifespan of fiberglass mat tissue in outdoor applications?

- The expected lifespan of fiberglass mat tissue in outdoor applications can vary depending on various factors such as exposure to weather conditions, maintenance, and quality of the material. However, on average, fiberglass mat tissue is designed to have a lifespan of around 20 to 30 years in outdoor applications. Fiberglass mat tissue is commonly used for reinforcing and providing strength to surfaces in outdoor applications such as roofing, construction, and automotive industries. It is known for its durability, resistance to moisture, and ability to withstand harsh weather conditions. To ensure a longer lifespan for fiberglass mat tissue in outdoor applications, it is crucial to properly maintain and protect it. Regular inspections, cleaning, and repairs when necessary can help prevent any potential damage or deterioration. Additionally, applying protective coatings or sealants can further enhance its resistance to UV rays, moisture, and other environmental factors. It's important to note that the lifespan of fiberglass mat tissue can vary depending on the specific application and the quality of the material used. Therefore, it is recommended to consult with the manufacturer or a professional in the industry to determine the expected lifespan for a specific project or application.

- Q: Does fiberglass mat tissue have any fire-resistant properties?

- Fiberglass mat tissue indeed possesses fire-resistant properties. Its composition of glass fibers and a thermosetting resin inherently grants it fire resistance. When subjected to high temperatures or flames, fiberglass mat tissue resists ignition and combustion, instead hindering flame propagation and aiding fire containment. As a result, fiberglass mat tissue proves suitable for fire protection necessities in various applications, including insulation, fire barriers, and fireproof panels. Nevertheless, it is crucial to acknowledge that although fiberglass exhibits fire resistance, it remains susceptible to melting or burning in extreme circumstances.

- Q: What are the different grades of fiberglass mat tissue available?

- There are several different grades of fiberglass mat tissue available in the market. These grades vary in terms of their weight, thickness, and strength. The most common grades include lightweight, medium-weight, and heavyweight fiberglass mat tissue. Lightweight fiberglass mat tissue is generally thinner and lighter in weight compared to other grades. It is often used for applications where flexibility and ease of handling are important. This grade is suitable for projects such as laminating lightweight structures, mold making, and repairs. Medium-weight fiberglass mat tissue is a versatile option that offers a balance between strength and flexibility. It is commonly used for various applications such as boat building, automotive repairs, and general fiberglass reinforcement. This grade provides adequate strength while still being manageable to work with. Heavyweight fiberglass mat tissue is the thickest and heaviest grade available. It offers superior strength and durability, making it ideal for applications that require high structural integrity. This grade is commonly used in industries such as construction, aerospace, and marine, where strength and toughness are crucial. Aside from these basic grades, there may be variations and special grades available depending on the manufacturer and specific requirements of a project. It is important to consult with a supplier or manufacturer to determine the most suitable grade of fiberglass mat tissue for a particular application.

- Q: Is the Teflon gasket filled with fiberglass or graphite?

- The molecular formula of E is similar to that of FFKM. FFKM is more resistant to temperature than PTFE, and has elasticity at 327 degrees!

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Yes, fiberglass mat tissue can be used for repairing fiberglass canoes. Fiberglass mat tissue is a lightweight material that is typically used for reinforcing fiberglass structures. It is commonly used in boat repairs as it provides strength and durability to the repaired area. The mat tissue is designed to be easily molded and shaped, making it ideal for repairing curved surfaces such as canoes. Additionally, fiberglass mat tissue is compatible with polyester and epoxy resins, which are commonly used in fiberglass repairs. Therefore, it is a suitable material for repairing fiberglass canoes and will help restore the structural integrity of the damaged areas.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 500g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords