Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 600g-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

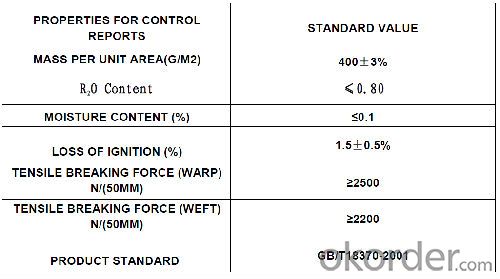

Woven roving Specification:

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for creating molds?

- Using fiberglass mat tissue for creating molds is not possible. Fiberglass mat tissue is primarily utilized as a reinforcement layer in fiberglass composite applications due to its thin and lightweight nature. It is not intended to be used as a material for making molds. Instead, molds are commonly made using silicone, resin, or plaster, as these materials have the capacity to capture intricate details and offer a polished surface finish.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Good acoustical performance is provided by fiberglass mat tissue. This material, composed of fine glass fibers, effectively absorbs sound waves and reduces echo and reverberation in a space. It possesses outstanding sound absorption properties, making it suitable for use in construction, automotive, and aerospace industries. The ability of fiberglass mat tissue to dampen sound and enhance acoustics makes it a favored option for soundproofing walls, ceilings, and floors in buildings. Moreover, its lightweight nature and ease of installation further contribute to its appeal for acoustical applications.

- Q: What are the main applications of fiberglass mat tissue?

- The main applications of fiberglass mat tissue include reinforcement in the construction industry for roofing, walls, and flooring, as well as insulation in thermal and acoustic systems. It is also used in the manufacturing of automotive parts, boats, and pipes for their strength and durability. Additionally, it finds use in the production of printed circuit boards and as a filtration medium in air and liquid filtration systems.

- Q: What are the different surface textures available for fiberglass mat tissue?

- Some of the different surface textures available for fiberglass mat tissue include smooth, coarse, textured, embossed, and patterned.

- Q: How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue performs well in terms of moisture vapor resistance. It is highly resistant to moisture vapor, preventing its penetration and protecting the underlying materials. The tightly woven fibers of the tissue create a barrier that limits the transfer of moisture, making it an effective choice for applications where moisture control is crucial.

- Q: Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Yes, fiberglass mat tissue can be used for repairing fiberglass fenders. Fiberglass mat tissue is a versatile material that is commonly used in fiberglass repair work. It is often used as a reinforcement layer to add strength and durability to the repaired area. When repairing fiberglass fenders, the damaged or cracked area can be repaired by applying a layer of resin and then laying the fiberglass mat tissue over it. The mat tissue is then saturated with additional resin to create a strong bond and ensure a smooth finish. This process helps to restore the structural integrity of the fender and provide a seamless repair. However, it is important to note that the success of the repair depends on the extent of the damage and the skill of the person performing the repair.

- Q: Can fiberglass mat tissue be used for reinforcing pipes?

- Yes, fiberglass mat tissue can be used for reinforcing pipes. It provides strength and durability to the pipe structure, making it resistant to cracks and leaks.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is greatly influenced by its thickness. Thicker mat tissues generally offer superior strength and durability compared to thinner ones. When the mat tissue is thicker, there is a higher proportion of resin to glass, resulting in increased stiffness and toughness. This higher resin content improves the overall structural integrity and mechanical properties of the mat tissue, reducing the risk of delamination and enhancing resistance to impact and fatigue. Furthermore, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a greater concentration of fibers, enhancing the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to consider the specific application and requirements when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more costly. Therefore, it is crucial to strike a balance between the desired performance characteristics and practical considerations such as weight, cost, and ease of installation.

- Q: Can fiberglass mat tissue be used in corrosive environments?

- Fiberglass mat tissue can be used in corrosive environments to some extent, but its resistance to corrosion depends on the specific composition and quality of the material. Fiberglass mat tissue is typically manufactured using a combination of fiberglass strands and a binder material. While fiberglass itself is generally resistant to corrosion, the binder material used in the mat tissue can vary and affect its resistance to corrosive environments. Some binders may provide better protection against corrosion, while others may be more susceptible to degradation. To enhance the corrosion resistance of fiberglass mat tissue in corrosive environments, additional protective coatings or treatments can be applied. These coatings can provide a barrier against the corrosive elements and extend the lifespan of the material. It is important to consider the specific corrosive environment and consult with experts or manufacturers to determine the suitability of fiberglass mat tissue for a particular application. They can provide guidance on the ideal composition, treatment, and any necessary precautions to ensure optimal performance and durability in corrosive environments.

- Q: How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue does not directly affect its conformability. Conformability is primarily determined by the flexibility and pliability of the material itself, rather than its width.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 600g-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords