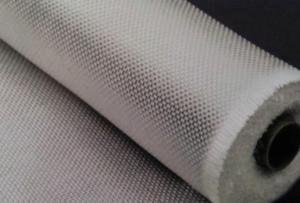

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

E-glass woven roving Fabric is bidirectional fabric made by 4.5 microns to 17 microns of E-Glass fiber,its high strength ,high modulus ,acid and alkali resistance , high temperature resistance and other properties. often used in protection ,heat insulation ,thermal insulation ,support field . After surface treatment ,it can be made into perfect composite materials . now it is widely used in hand lay up and robot processes to manufacture boats ,vessels ,plane and automotive parts , furniture and sports facilities.

Specifications:

PRODUCT CODE | WOVEN WEIGHT (OZ/YD) | WOVEN WEIGHT (GSM) | STANDARD WIDTH (INCHES) | ROLL LENGTH (M) | THICKNESS (MM) | LOI % | Moisture Content (%) |

CT-PWR24 | 0.86 | 24 | 50 | 50M | 0.04 | ≤0.80 | ≤0.20 |

CT-PWR48 | 1.71 | 48 | 50 | 50M | 0.06 | ≤0.80 | ≤0.20 |

CT-PWR100 | 2.95 | 100 | 50 | 50M | 0.11 | ≤0.80 | ≤0.20 |

CT-PWR135 | 3.99 | 138 | 50 | 50M | 0.14 | ≤0.80 | ≤0.20 |

CT-PWR200 | 5.9 | 200 | 50 | 50M | 0.18 | ≤0.80 | ≤0.20 |

CT-PWR290 | 8.56 | 290 | 50 | 50M | 0.23 | ≤0.80 | ≤0.20 |

Main features:

1.warp and weft rovings aligned in a parallel,flat manner and uniform tension.

2.densely aligned fiber,providing high dimensional stablity and easy handing.

3.good moldability,fast and complete resin wet-out ,enabling high productivity

4.good transparency and high strength of the composite products

Remark:Woven rovings are available in the width range of 50-3000mm and the weight range of 200-1600g/m2

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The ability of fiberglass mat tissue to maintain its size and shape under different conditions is referred to as its dimensional stability. Fiberglass mat tissue is well-known for its outstanding dimensional stability, which makes it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, where glass fibers are bonded together using a binder material. Not only does this binder ensure the integrity of the mat tissue, but it also helps it maintain its dimensional stability over time. Moreover, the exceptional dimensional stability of fiberglass mat tissue is further enhanced by its inherent properties, such as its high strength and stiffness. These characteristics have made fiberglass mat tissue a popular choice in various industries, including construction, automotive, and aerospace, where maintaining consistent dimensions is essential for optimal performance and durability.

- Q: What is the moisture resistance of fiberglass mat tissue?

- The moisture resistance of fiberglass mat tissue is generally quite high. The material is typically made from fiberglass strands that are tightly woven together, creating a dense and water-resistant surface. This makes it highly effective in applications where moisture exposure is common, such as in the construction industry for roofing, insulation, and waterproofing purposes. Additionally, fiberglass mat tissue is often treated with special coatings or additives that further enhance its moisture resistance, making it even more durable and reliable in wet or humid environments. Overall, the moisture resistance of fiberglass mat tissue is a significant advantage and contributes to its widespread use in various industries.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Automotive panel repairs can be effectively carried out using fiberglass mat tissue. This material is known for its versatility and durability, making it a popular choice in the automotive industry. It proves particularly useful in reinforcing and restoring weakened or damaged areas on automotive panels. By providing a strong and stable foundation, fiberglass mat tissue is capable of repairing dents, cracks, and holes in panels. Its pliability allows for easy shaping and molding to fit the contour of the panel. Furthermore, fiberglass mat tissue's resistance to rust and corrosion makes it a reliable option for automotive repairs that must endure harsh weather conditions and road debris. Overall, fiberglass mat tissue is widely utilized due to its strength, durability, and versatility, making it an ideal choice for automotive panel repairs.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: Can fiberglass mat tissue be used for insulating exterior walls?

- Yes, fiberglass mat tissue can be used for insulating exterior walls. Fiberglass mat tissue is a type of insulation material that is commonly used for its excellent thermal and acoustic insulation properties. It is made of fine glass fibers that are bonded together with a binder, creating a flexible and lightweight material. When used for insulating exterior walls, fiberglass mat tissue is typically installed between the wall studs or in the wall cavities. It helps to reduce heat transfer by trapping air within its fibers, which acts as a barrier against heat loss or gain. This insulation material can significantly improve the energy efficiency of a building by reducing the need for heating or cooling, thereby reducing energy costs and carbon emissions. Fiberglass mat tissue is also resistant to moisture, mold, and mildew, making it suitable for exterior applications. It helps to create a more comfortable and healthier indoor environment by preventing the growth of harmful microorganisms and reducing condensation. Additionally, fiberglass mat tissue is fire-resistant, adding an extra layer of safety to the building. Overall, fiberglass mat tissue is a versatile and effective insulation material that can be used for insulating exterior walls. Its thermal, acoustic, moisture resistance, and fire-resistant properties make it an excellent choice for improving the energy efficiency and comfort of buildings.

- Q: What is the delamination strength of fiberglass mat tissue?

- The delamination strength of fiberglass mat tissue refers to its ability to resist separation or peeling of layers within the material. It is a measure of the adhesive strength between the fibers and the binder in the mat. The specific delamination strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, binder type, and overall composition of the material.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units.

- Q: Does fiberglass mat tissue provide any acoustic insulation?

- Yes, fiberglass mat tissue provides acoustic insulation as it effectively absorbs and dampens sound waves, reducing noise transmission and improving soundproofing properties.

- Q: Can fiberglass mat tissue be recycled?

- Indeed, recycling is a viable option for fiberglass mat tissue. Fiberglass, composed of glass fibers and resin, allows for reusing both elements. To recycle, the glass fibers and resin are separated, typically via mechanical grinding or melting techniques. The isolated fibers are subsequently employed in the production of fresh fiberglass products like insulation, roofing materials, or even new fiberglass mat tissue. The recycling of fiberglass plays a critical role in lessening the environmental impact of this material by diverting it from landfills and conserving valuable resources. It's important to acknowledge, however, that the recycling process can be intricate and costly, which means not all recycling facilities may accept fiberglass mat tissue.

- Q: How does the fiber content of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is directly influenced by its fiber content. As the fiber content increases, the strength of the tissue also increases. This is because the fibers provide the necessary structural integrity and reinforcement to the material. When the fiber content is raised, it results in a greater concentration of fibers, thereby boosting the overall strength of the tissue. Fiberglass mat tissue is comprised of randomly oriented glass fibers that are bound together with a resin binder. These fibers are responsible for carrying the load and resisting any external forces or stresses applied to the material. Consequently, the more fibers present in the tissue, the higher the load-carrying capacity and strength of the material. Moreover, a higher fiber content enhances the stiffness of the fiberglass mat tissue. Stiffness refers to the material's ability to resist deformation or bending under applied loads. With a larger quantity of fibers, the tissue becomes stiffer, making it less susceptible to bending or flexing. This increased stiffness contributes significantly to the overall strength of the material. It is important to note that while a higher fiber content improves the strength of fiberglass mat tissue, there is an optimal range where the benefits of additional fibers are maximized. Beyond this range, increasing the fiber content may not result in a substantial improvement in strength, and it may begin to have diminishing returns. Therefore, striking the right balance between fiber content and strength is crucial for specific applications. In conclusion, the strength of fiberglass mat tissue is directly affected by its fiber content. Increasing the fiber content leads to a higher concentration of fibers, thereby enhancing the material's load-carrying capacity and stiffness. Finding the optimal fiber content is essential for maximizing the strength of the tissue in specific applications.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 800g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords