Disposable Aluminum Grill Sheets - 8011 Aluminum Stucco Coil for Decoration/Air-Conditioner/Can Body/Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

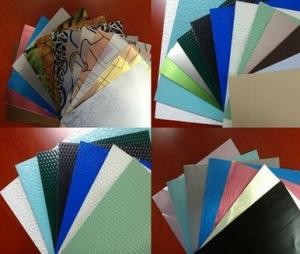

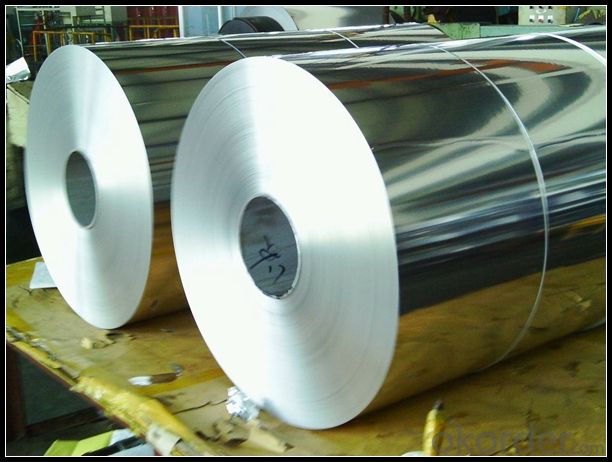

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors. Aluminum is a highly conductive metal, which makes it an excellent choice for transferring electric current. It has a low electrical resistance, allowing for efficient transmission of electricity. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular material for electrical connectors in various industries such as automotive, aerospace, and electronics. However, it is important to note that aluminum connectors may require additional measures to prevent galvanic corrosion when used with dissimilar metals.

- Q: What is the density of aluminum plate?

- Aluminum density and structure:The density of aluminum is about 2.7, about 1/3 of the average metal, and the conductivity of common aluminum conductors is about 61% of copper and half of that of heat. Although pure aluminum is very soft and malleable, it can still be hardened by cold working and by alloy. Bauxite is an important source of aluminum. It takes about two pounds of bauxite to make a pound of alumina, and two pounds of alumina is needed to make a pound of aluminum

- Q: Are aluminum sheets suitable for architectural facades?

- Yes, aluminum sheets are highly suitable for architectural facades. They offer numerous benefits such as durability, lightweight construction, corrosion resistance, and versatility in design. Aluminum sheets can be easily shaped and formed into various sizes and shapes, allowing for creative and unique architectural designs. Additionally, their ability to withstand harsh weather conditions makes them a reliable choice for long-lasting facades.

- Q: Can aluminum sheets be polished?

- Certainly, aluminum sheets are capable of being polished. Aluminum, being a relatively malleable metal, lends itself to easier polishing in comparison to harder metals like stainless steel. The act of polishing aluminum sheets entails the utilization of abrasive substances such as sandpaper or polishing compounds. This serves to eliminate any blemishes, scratches, or oxidation present on the surface. Typically, the process involves multiple stages of polishing, employing varying degrees of grit in sandpaper or polishing compounds. Step by step, a smoother and more reflective surface is attained. Polished aluminum sheets find common usage in various applications, including automotive components, architectural elements, and ornamental objects. The polishing process elevates the metal's aesthetic appeal, imparting a glossy and reflective finish.

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Indeed, the utilization of aluminum sheets is possible in the production of heat exchanger fins. Owing to its remarkable thermal conductivity and resistance to corrosion, aluminum stands as a frequently employed substance in heat exchangers. The lightweight and easily malleable attributes of aluminum sheets render them exceptionally suitable for the creation of fins that possess an extensive surface area, thereby augmenting heat transfer. Furthermore, aluminum is readily accessible and cost-efficient, solidifying its status as a favored selection within the realm of heat exchanger manufacturing.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is a lightweight and durable material that offers a variety of benefits for automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, roofs, and other components. The use of aluminum sheets in automotive applications helps to reduce the overall weight of the vehicle, which improves fuel efficiency and performance. Additionally, aluminum has excellent corrosion resistance properties, making it ideal for withstanding harsh weather conditions and road salt exposure. Furthermore, aluminum can be easily formed and shaped, allowing for complex designs and intricate detailing on automotive parts. Overall, the use of aluminum sheets in automotive applications contributes to the production of lighter, more fuel-efficient, and aesthetically appealing vehicles.

- Q: What is the most efficient and low cost method for welding 1mm-3mm aluminum sheet?,What's new?

- If the cost is low, or belongs to the welding; and to stress the process of words, or to inert gas welding (TIG or MIG), and can use tungsten arc alternating current arc welding or tungsten arc argon arc welding.

- Q: This question asks about the energy savings achieved by using aluminum sheets in comparison to other materials.

- <p>The energy savings achieved by using aluminum sheets instead of other materials can be significant. Aluminum is lightweight and has excellent thermal conductivity, which means it can reduce energy consumption in applications like building insulation and heat exchangers. For instance, aluminum-framed buildings can save up to 40% more energy than those made with traditional materials due to better insulation properties. Additionally, in industrial processes, aluminum's high thermal conductivity can lead to energy savings of around 33% compared to using copper in heat exchangers. The exact amount of energy saved depends on the specific application and the materials being replaced.</p>

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

Send your message to us

Disposable Aluminum Grill Sheets - 8011 Aluminum Stucco Coil for Decoration/Air-Conditioner/Can Body/Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords