Aluminum Roof Sheets - Directing Pass Aluminium Strips for Second Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Directing Pass Aluminium Strips for Secondly Rolling

Directing Pass Aluminium Strips for Secondly Rolling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Directing Pass Aluminium Strips for Secondly Rolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

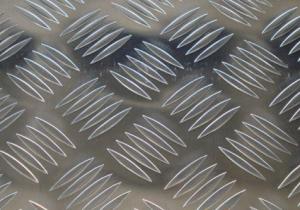

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- To prevent oxidation of exposed edges of aluminum sheets, there are a few effective methods that can be employed: 1. Apply a protective coating: One of the most common ways to prevent oxidation is by applying a protective coating on the exposed edges of aluminum sheets. This can be done using various types of coatings, such as paint, lacquer, or a specialized protective coating designed specifically for aluminum. These coatings act as a barrier, preventing the aluminum from coming into contact with oxygen and moisture, which are the primary causes of oxidation. 2. Use anodizing: Anodizing is a process in which a protective oxide layer is created on the surface of aluminum. By subjecting the aluminum sheets to an electrolytic process, a controlled and thick layer of oxide is formed, which acts as a barrier against oxidation. Anodizing also provides additional benefits such as improved corrosion resistance and enhanced aesthetics. 3. Implement proper storage and handling: Proper storage and handling practices can also help prevent oxidation of exposed edges. Aluminum sheets should be stored in a dry and well-ventilated area, away from moisture and humidity. It is important to avoid storing aluminum sheets directly on the ground or other surfaces that may cause them to come into contact with moisture. Additionally, gloves should be worn during handling to minimize the transfer of oils from the skin, which can accelerate oxidation. 4. Regular cleaning and maintenance: Regular cleaning and maintenance of aluminum sheets can help prevent oxidation. This involves removing any dirt, grime, or other contaminants that may accumulate on the surface, as they can contribute to the oxidation process. Cleaning can be done using mild soaps or detergents, and a soft cloth or sponge. After cleaning, it is important to thoroughly dry the aluminum sheets to remove any remaining moisture. By implementing these preventive measures, the oxidation of exposed edges of aluminum sheets can be effectively minimized, ensuring their longevity and maintaining their aesthetic appeal.

- Q: Is it possible to construct furniture using aluminum sheets?

- <p>Yes, you can use aluminum sheets to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material that is often used in modern furniture design. It can be easily shaped and welded, making it suitable for a variety of furniture pieces such as tables, chairs, and shelving. However, it's important to consider the design and structural integrity, as well as the finish and comfort, when creating furniture with aluminum. It's also advisable to use appropriate tools and techniques to ensure safety and quality in the construction process.</p>

- Q: Remember the notorious Chevy Vega of the 1970's? As I recall,one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs arealso equipped with aluminum engines to reduce curb weightand improve fuel efficiency. Will they be prone to the sameproblems that the Vega had down the road? Are there othermanufacturers that have used aluminum engines with successrecently?

- This Site Might Help You. RE: how reliable are today's aluminum block engines? Remember the notorious Chevy Vega of the 1970's? As I recall, one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs are also equipped with aluminum engines to reduce curb weight and improve fuel efficiency. Will they be prone to...

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

- Q: This question asks for methods to protect aluminum sheets from damage during the installation process.

- <p>To prevent damage to your aluminum sheets during installation, follow these steps: Use protective gloves to avoid scratches from hand contact. Handle the sheets with care, especially at the edges and corners. Keep the surface clean and dry to prevent any dirt or moisture that could cause damage. Use appropriate tools designed for aluminum to avoid marring the surface. Ensure the installation site is free from debris that could cause scratches or dents. Install the sheets in a controlled environment to avoid exposure to harsh weather conditions. Finally, consider using a protective film or cover on the aluminum sheets until they are fully installed.</p>

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: What type of aluminum plate does the traffic sign use? 1100?

- Model is not important, can meet the standard requirements on the line!

- Q: Can aluminum sheets be used for fencing?

- Certainly, fencing can make use of aluminum sheets. Aluminum, being a flexible substance, is both lightweight and long-lasting, as well as resistant to corrosion. It is frequently employed in fencing due to its capacity to withstand severe weather conditions, involving rain, snow, and UV rays. Aluminum sheets can be conveniently transformed into various fence styles and designs, such as picket fences, privacy fences, or decorative fences. Moreover, aluminum fencing necessitates minimal upkeep since it does not rust or decay like other materials including wood or iron. In general, aluminum sheets offer a splendid choice for fencing due to their durability, endurance, and aesthetic allure.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- Simply put, 6061 and 6063 belong to the 6 series, 6061 hardness in 90HB 6063 in 80HB, suitable for brazing, surface oxidation treatment is better,

Send your message to us

Aluminum Roof Sheets - Directing Pass Aluminium Strips for Second Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords