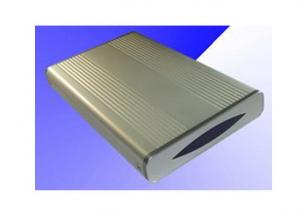

High Quality Aluminum Standard Profiles Die Cast Aluminum Enclosure

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Die Cast Aluminum Enclosure Description:

Die Cast Aluminum Enclosures are from 150 ton to 2500 ton which provide the wide range of cast part sizes from 0.4” square to over 2’ square. Our world class tooling technology offers solid tools and the plenty experiences of casting parameters control that make our casting parts are accurate, durable and exquisite to compare with the other workmanship. Our competitive offshore price and short first article lead time delivers the fast success of your project.

2.Main Features of the Die Cast Aluminum Enclosure:

·can be easily installed or moved.

·Free from corrosion and carry superior insulation.

·passed waterproof and dustproof carried out under rigid quality standard

·The use is also convenient for the installation of Terminal Substitution Rail, Button Box, Small Terminal,Signal , Relay and Sensor

3. Die Cast Aluminum Enclosure Images

4. Die Cast Aluminum Enclosure Specification

Product Class: | die cast aluminum enclosure | ||

Material: | Aluminum & Aluminum alloy A360, A380, A356, ADC12,ADC10, | ||

weight | 0.02-15 kg ( Tolerance :+/- 0.5mm) | ||

Manufacture Process | 1) Process: die cast aluminum enclosure/Metal alloy die casted parts /gravity casting products 2)Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing 3) Surface Finish: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis | ||

Surface Treatment | 1)Sand blasting 2)Zinc/chrome plating 3)Powder coating 4)Anodizing 5)Oil injection 6)Brush .etc | ||

Production usage

| 1)Auto parts casting 2)Motorcycle parts 3)Chair parts 4)Locomotive parts 5)Machinery parts 6)Tool parts 7)Radiator 8)Die cast aluminum enclosure .etc | ||

Service | OEM/ODM service are welcomed | ||

Competitive advantage | 1) Small quantity order acceptable 2)Very tight tolerance. 3)Advanced equipment, excellent R&D teams. 4)Strict quality control system. 5)Professional technics and rich experience. 6)Packaging details as client required. | ||

Certification | ISO9001/TS16949,ISO14001,7S |

5.FAQ

1.What is your mOQ?

1000pieces

2. How about your delivery time?

About one month

3.How to order?

First,Customers could send us your sample or drawing,such as 2D and 3D drawing(IGS or STP format) Second,Our engineers will check the drawing carefully and then provide you a better price. Third, If you accept, then order confirmed.

- Q: Industrial aluminum profiles are generally used in what industry?

- Kunshan Austrian crown aluminum to tell you: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, electronic machinery industry and clean room with.

- Q: This question asks for methods to prevent corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion of aluminum profiles during installation, follow these steps: 1. Use stainless steel fasteners and avoid galvanized or carbon steel screws which can cause galvanic corrosion. 2. Keep the aluminum profiles clean and dry during installation to avoid contact with moisture which can initiate corrosion. 3. Apply a protective coating or sealant to the profiles, especially at cut edges where the protective oxide layer may be compromised. 4. Store aluminum profiles in a dry, cool place before installation to prevent moisture absorption. 5. Regularly inspect and maintain the profiles to identify and address any signs of corrosion early. By adhering to these practices, you can significantly reduce the risk of corrosion on aluminum profiles during installation.</p>

- Q: Can aluminum profiles be used in the production of audiovisual equipment?

- Yes, aluminum profiles can be used in the production of audiovisual equipment. Aluminum is a lightweight and durable material that can be easily molded into various shapes and designs. It offers excellent heat dissipation properties and is resistant to corrosion, making it suitable for audiovisual equipment such as speaker stands, camera mounts, and TV brackets. Additionally, aluminum profiles can be customized to fit specific requirements, providing flexibility in design and construction.

- Q: Are aluminum profiles suitable for the furniture industry?

- Yes, aluminum profiles are highly suitable for the furniture industry. Aluminum is a versatile and durable material that offers numerous benefits for furniture manufacturing. Firstly, aluminum profiles are lightweight, making them easy to handle and transport, especially for bulky furniture items. This feature not only reduces transportation costs but also makes the furniture more user-friendly during installation and rearrangement. Secondly, aluminum is highly resistant to corrosion, ensuring that furniture made with aluminum profiles will withstand harsh weather conditions and remain durable over time. This makes it suitable for both indoor and outdoor furniture applications. Another advantage of aluminum profiles is their design flexibility. Aluminum can be easily extruded into various shapes and sizes, allowing for endless design possibilities. This versatility facilitates the creation of customized furniture pieces to meet specific client requirements. Aluminum profiles also offer excellent strength-to-weight ratio, making furniture made with aluminum sturdy and long-lasting. This feature is particularly beneficial for items that undergo regular use, such as chairs and tables. Furthermore, aluminum is a sustainable material as it is 100% recyclable. This aligns with the growing demand for environmentally-friendly furniture options. Manufacturers can easily recycle aluminum profiles at the end of their lifecycle and use the recycled material to create new furniture items, reducing waste and contributing to a circular economy. Overall, the unique properties of aluminum profiles make them highly suitable for the furniture industry. Their lightweight nature, corrosion resistance, design flexibility, strength, and recyclability all contribute to creating high-quality and sustainable furniture products.

- Q: This question asks for a list of various fastening methods used to connect aluminum profiles to the structural frames of buildings.

- <p>There are several types of fasteners used to attach aluminum profiles to building frames, including: 1) Bolts and Nuts: Commonly used for strong, secure connections. 2) Rivets: Provide a permanent connection that is resistant to vibration. 3) Self-Tapping Screws: Can be used in materials without pre-drilling. 4) Structural Glue: Offers a strong bond and is often used in combination with mechanical fasteners. 5) Welding: Used for permanent, load-bearing connections, though not common for aluminum due to the risk of thermal distortion. 6) Clamps and Brackets: Used for temporary or adjustable connections. 7) Adhesive Tapes: Provide a quick and easy method of attachment, though not as strong as other methods. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: Identify the key elements to evaluate when choosing aluminum profiles for a particular project.

- <p>When selecting aluminum profiles for a specific project, consider the following factors: 1) Load-bearing capacity, ensuring the profile can support the intended weight and stress; 2) Dimensional stability, to maintain structural integrity over time; 3) Corrosion resistance, especially for outdoor or humid environments; 4) Aesthetics, matching the profile's appearance with the project's design; 5) Cost-effectiveness, balancing quality with budget constraints; 6) Availability of the profile, considering lead times and supply chain reliability; 7) Ease of fabrication and assembly, which can affect construction time and labor costs; 8) Thermal properties, important for energy efficiency in buildings; 9) Compliance with industry standards and regulations; 10) Customizability, for projects with unique specifications or design requirements.</p>

- Q: What are the water-resistant properties of aluminum profiles?

- Aluminum profiles possess excellent water-resistant properties due to their inherent corrosion resistance. The aluminum surface forms a thin oxide layer that acts as a protective barrier against moisture and prevents water penetration. This makes aluminum profiles highly resistant to rust, rot, and degradation caused by water exposure, making them ideal for various applications in outdoor and wet environments.

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Yes, aluminum profiles are suitable for medical equipment and devices. Aluminum is a versatile material that offers several advantages for medical applications. Firstly, it is lightweight, making it ideal for portable medical devices. This allows for ease of transportation, especially in emergency situations. Additionally, aluminum is corrosion-resistant, which is crucial for maintaining the sterility and cleanliness of medical equipment. The material is also durable and can withstand harsh environments and regular cleaning and sterilization procedures. Furthermore, aluminum profiles can be easily customized and fabricated into various shapes and sizes, making them adaptable for different medical device designs. Overall, the properties of aluminum make it a reliable and suitable choice for medical equipment and devices.

- Q: How about the price of aluminum profile?

- Aluminum prices are calculated according to the price of aluminum ingot + processing fees, such as: aluminum ingot price 16000+, processing fee 6000 = 22000 yuan / ton

Send your message to us

High Quality Aluminum Standard Profiles Die Cast Aluminum Enclosure

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords