Cu- CuNi (Constantan) thermocouple (Type T) A quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Pass: ISO9001 certification

2.fine after-sale services

3.small order accepted

4.samples available

5.short delivery time

Cu-Ni resistance heating wire and strips

electrothermal resistance wires

copper nickel electrical alloy wires and strips

resistance alloy wires or strips

electrical wires

copper nickel resistance alloy

copper nickel wires and strips

1. Introduction

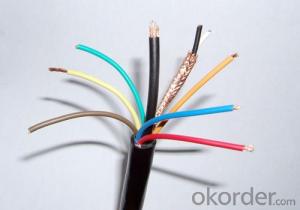

The copper-based low resistance heating alloy is widely used in low-voltage circuit breaker, thermal overload relay, and other low-voltage electrical product. It is one of the key materials of the low-voltage electrical products. The materials produced by our company have the characteristics of good resistance consistency and superior stability. We can supply all kinds of round wire, flat and sheet materials.

2.Marking

Each spool/package of alloy is supplied with a label or tag showing alloy type, nominal size, tare and net weight, resistance W/m (W/ft), charge number and a reference number.

3.size

wires:0.018-10mm Ribbons:0.05*0.2-2.0*6.0mm

Strips:0.5*5.0-5.0*250mm Bars:D10-100mm

Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock, The quantity based on the material type, The buyer should bear all the shipping costs.

Please feel free to send us a inquiry and we are looking forward to cooperating with you!

FACTORY

PACKING

| Characteristic Grade | Resistivity ( 200C μΩ.m) | Max.working Temperature ( 0C) | Tensile Strength (Mpa) | Melting point (0C) | Density ( g/cm3) | TCR x10-6/ 0C (20~600 0C) | EMF vs Cu (μV/ 0C) (0~100 0C) |

| NC003 (CuNi1) | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

| NC005 (CuNi2) | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

| NC010 (CuNi6) | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

| NC012 (CuNi8) | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

| NC015 (CuNi10) | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

| NC020 (CuNi14) | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

| NC025 (CuNi19) | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

| NC030 (CuNi23) | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

| NC035 (CuNi30) | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

| NC040 (CuNi34) | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

| NC050 (CuNi44) | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

- Q: I have a two year old cat that I love to death but she is always chewing on wires (Her latest our new LCD TV Wire) . She has lots of different toys but she still goes back to the wires. It is getting real expensive and I don't know what to do any suggestion? Is this normal for a full grown cat?

- Hello, I just answered another person with the same problem. The lady chose my answer as the best : ) I suggest either hot sauce on the wires, wipe the wires with hot sauce, just enough to deter your cat. Or, there are cat repellents at the pet stores. Spray it on the wires, it has a smell that cats and dogs don't like. Only thing is with the repellent you have to do it every 24 hours as the smell wears off. Like I told the other lady earlier. I have seen many cats that have gotten hurt by chewing on electrical cords through the years. But, there is one that stands out in my mind the most. He was such a sweet cat too. One whole side of his face was disfigured because he chewed on wires. That is a very dangerous thing for any animal to do. You have to stop your cat as soon as possible before some thing happens to him. Hope this helps as I don't want to see any thing happen to your cat.

- Q: I live in a home that is 50 plus years old. All of the electrical outlets in the home are the out dated 2 prong plug ins. Are there any safety issues associate with replacing the outdated 2 prong outlet with a 3 prong outlet to power a metal halide high bay light fixture with a 400 watt ballast? The wiring in the wall is also outdated and does NOT have the up to date 3 wire electrical supply.

- No, because the fixture has a transformer, and if the transformer fails it can energize the metal parts of the fixture. The purpose of a ground is to provide a current path to ground from the chassis to operate the overcurrent device if the chassis becomes energized. Without a ground wire the current may find another current that may ignite combustibles.

- Q: Does anyone know what the voltage means on electrical wire sheathing? Some 14AWG wires show 600V and others are 800V.I have a burnt wire that shows 1000V.They are all 14AWG, stranded, copper wire. I just don't know what the voltage rating means. Does the wire support up to that many volts or does the sheath resist heat better the higher the number is?

- It probably means that the insulation on the wire conforms to some standard, and that the cable may LEGALLY be used for permanent wiring in a building at voltages up to whatever number. It's not about heat. When power wiring in a building gets hot, it's strictly because of the amperage that the circuit is carrying, not the voltage. High voltages are a problem because of the tendency to arc. Electric fields are measured in Volts/meter (i.e., the voltage difference between two conductors, divided by the distance between them.) Any given electric insulator will break down and allow current to flow if the field strength is high enough. Cables that are rated for higher voltages either use an insulating material that has a higher dielectric strength (i.e., able to withstand stronger fields), or they use bulkier insulation, so that the distance between the conductors is greater.

- Q: It hurts, and then you will be detours later, but the poles are still there! What is the original statement of that sentence! The More

- Installed system, if the system will pay attention to the contents of the motherboard disk is the majority of the driver

- Q: I have several sets of track lights that are controlled by one switch (switch A). In those sets of track lights, i want to make another switch (switch B) for a particular track light to save electricity reason. Which electrical wire (black or white) should i break to make a switch for this track lights?

- Inline Light Switch

- Q: I am trying to understand exactly how 120v and a second signal can travel through the same wires without interference. Is there only certain voltages that will work (Like will 120v and 60v not work together)? Thanks

- I don't know details, but the data signals would be at a much higher frequency than the 60 Hz of the power, and much smaller than 120v. If you looked at it on an ocilloscope, you would see the 60hz power, and fuzzy ripples around that which would be your data signal.

- Q: I have a water pump that is connected directly to the electrical panel in my home. I want to cut the wire, install two extension cord ends, and re-connect the wire. By doing this, I will be able to unplug the pump from the electrical panel and plug it into a generator when needed.My question is whether I need to pay attention to polarity when connecting the extension cord ends? If I get the wires reversed, will it cause a problem? I guess if I reverse the wires on both the male and female ends, it should work fine when connected to the electrical panel (because both the male and female are reversed, which should net to the same thing). I am concerned about when I plug the thing into a generator. If I accidentally switch the wires around the wrong way, what will happen?

- Polarity is important sometimes, not in others. If you wire a DC motor backwards, it will go backwards. If you wire a DC car radio backwards, it will probably blow a fuse or die. If you wire an incandescent lamp (AC or DC) backwards, no problem. Except that in the US with screw fittings the centre stud is supposed to be live and the shell neutral so that if you touch the lamp shell you won't get a shock. With an AC 1-phase or universal motor, like your pump or an electric drill, it should not make any difference. Except that it may have a switch somewhere in the live wire. Newer models tend to have both wires switched. It is of course important not to get the ground and live wires crossed over (but it would not run). Crossing the ground and neutral is unsafe. It would run, maybe, but that would inject voltage into the ground all through the house and cause your TV and other electronics to hum like crazy, maybe die. Also maybe promote galvanic corrosion in your dishwasher and give you tingles from the water tap. As for connecting wires correctly, normally they are coloured or have a ridge along one wire. Generally there are standard colours in each country for live, neutral and ground and if you don't follow the rules it will confuse the heck out of anyone doing repairs later and maybe cause them to make unsafe connections. I can't see why you would be using unmarked wires, but if you are, you could use a meter and another length of wire to check continuity end-to-end after you are done to make sure it is the right way around.

- Q: I have two switches (one controls a fan and one controls a light) in a box with only one feed wire. The normal pigtail split is used for the blacks to the switches and the whites to the light and fan, ground to grounds. I have a timer with a black, red, white and ground that I will use to control the fan. Ground goes to ground, red goes to the fan, black gets connected to the existing blacks, for the white I pigtailed two short white wires with the white feed wire and connected one to the light switch white, and the other to the whites for the the fan and timer white (it works). Now the question Could I have connected the timer white with the whites for feed, the light and the fan or would that have caused a problem, (I thought it would so that is why I split the feed white off with the pigtail)

- It's only a question of what fits in the wire nut. When you buy wire nuts they come with a list of all of the different combinations of wires that will fit in them. Your way is fine - a bit of extra work is all.

- Q: Why is the wire hot when a short circuit occurs?

- The state does not specify that small plastic lines are generally 100 meters in packaging. The other looks at the size of the disk and the customer's own needs.

- Q: I use the rosin with the solder, like DIY mp. but I do not know why the wire hit tin tin was Asia opened, and no sticky, under the novice, ask for more advice

- Plastic wire belt is also known as: cable ties, cable ties, lock belt

Send your message to us

Cu- CuNi (Constantan) thermocouple (Type T) A quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches