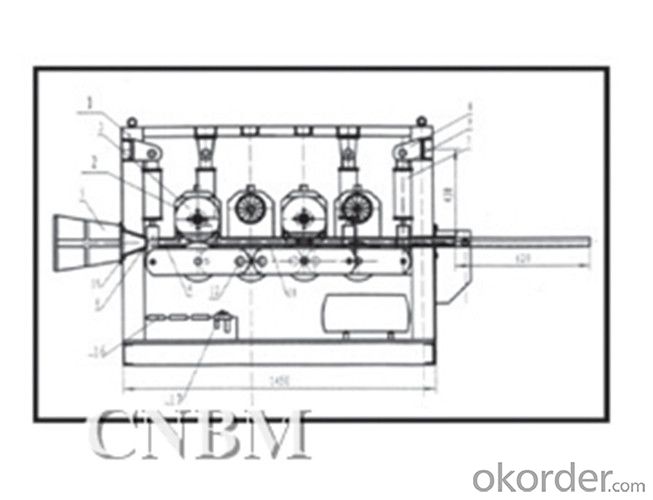

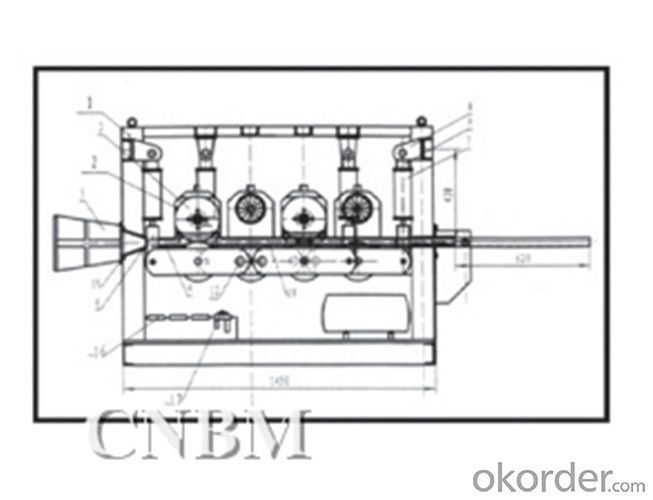

Cored Wire Feeding Machine for Metallurgy Industry(2 wires)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1,production line introduce(Wire Feeding Machine )

Multiple wire feeding machiens for cored wire or full wire is a heavy duty system characterized by its high degree of reliability , long life cycle, and production optimizations.

For all wire types, enables the wire or cored wire to be injected directly into the liquid steel at a variety of metallurgical stations reliablyu and with precision.

This is the most precise process of addition of small quantities of deoxidants , modifiers and alloying elments into molten steel or cast iron making the process efficient,economic

2,Main technical parameters(feeding equipment)

two stream feeding equipment(mobile)

Feeding type: alloy wire, aluminum wire, rectangular wire

Feeding number: 2

Feeding diameter: Ø8-Ø18mm

Feeding speed: 1-7 / s

Host moving speed: 14 / min

Conduit angle: 30 degrees

Wheelbase: 682mm (refer to the distance between the two tracks)

Power: main motor Y100L-4 3KwX6 units (single wire)

Moving motor Y90-4 1.5Kw

Use of power: 380V three-phase four-wire system

Host dimensions: 1100X850X1320mm

Moving rail: 11Kg /m

Machine type: fixed, moving, rotating (confirmed according to the scene)

- Q: How to do well the maintenance and maintenance of metallurgical machinery equipment

- Inadequate repair or excessive maintenance of equipment is a common problem in the maintenance management of metallurgical equipment at this stage. Because of the lack of equipment replacement in metallurgical industry, there are many differences in the type and condition of equipment. However, the enterprise is not willing to carry out regular maintenance of the equipment. The equipment can only be repaired when the equipment is not working, which results in the waste of equipment resources and the economic losses of the enterprise.

- Q: Metallurgical mechanical blade

- The cutting edge hardness of the mechanical blade used for cutting metal is generally above 60HRC. Wear resistance is the ability of materials to resist wear. Generally speaking, the higher the hardness of mechanical blade material, the better its wear resistance.

- Q: What kind of products are metallurgical equipment in iron and steel works?

- About equipment: continuous casting mold, which is the most important equipment, is the heart of continuous casting, most instructions are executed through the mold, including mold level control, mold level measurement, mould width, dynamic mold expert system, and other steel ladle, ladle nozzle manipulator, bending straightening machine, arc section of horizontal section, roll gap detecting device, hydraulic vibration device, billet guiding device and process control device.

Send your message to us

Cored Wire Feeding Machine for Metallurgy Industry(2 wires)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords