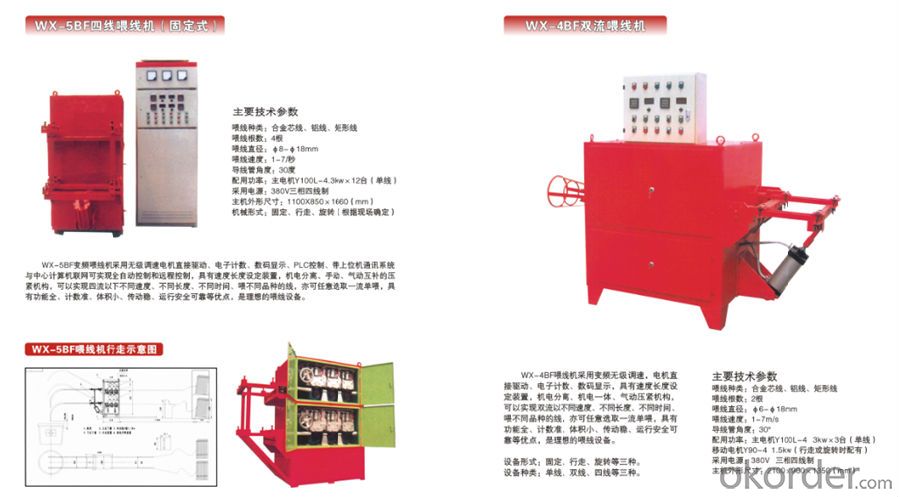

Cored Wire Feeding Machine for Metallurgy Industry(4 wires)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

l The main technical parameters of mechanical part of four lines feeding machine:

1 Type style: inside pumping

2 Type of line to feed: alloy cored wire, solid aluminum wire

3 Quantity of lines: 4

4 Diameter of wire to feed: 6-18mm round wire

5 Feed speed: 0-360m/min

6 Max length between the machine and the furnace: 4 meters.

7 Installation: Walking

8 Conduit ascending angle: 30 °

9 Rationed power: main motor 7.5KW x 4 station, walking motor 2.2KW x 1 station

10 Power: 380V Three phase four wires

11 Air supply: 4—6kg/cm

12 Single line power: 15KW

Total power: 60KW

13 Work mode: frequency control, manual control, PLC automatic control, with communication interface, DP bus control, single-line or multi-line wire feeding

14 Speed mode: single inverter power 18.5 KW x 2 sets

15 Length settings: Touch screen

16 The feeding line accuracy: ≤ 1 m / second

l The main technical performance:

It adopts frequency control, manual control, PLC automatic control, length display, as needed, feed speed, length and weight were selected and adjusted. Automatic wire withdrawal 0-800mm with feeding end, direct drive of reducer motor, display total wire length, feeding speed and the length, speed and weight can be preset.

Feeding machine is arranged on the platform, is walking, and operates with local control box.

- Q:Metallurgical mechanical blade

- To make the mechanical blade in under a lot of pressure, and often appear in the cutting process of shock and vibration conditions, without chipping and fracture, material mechanical blade must have sufficient strength and toughness.

- Q:How to do well the maintenance and maintenance of metallurgical machinery equipment

- The main problem in the management of metallurgical machinery and equipment is not systematic. At this stage, the metallurgical industry in China has many new and old equipment mix and match phenomenon, the management is also relatively confusing. Mainly because many enterprises pay more attention to the economic benefits, and pay little attention to the maintenance and maintenance of metallurgical equipment. This leads to the low level of equipment management in the metallurgical industry, and may cause various equipment management problems, so that the service life of various equipment will be reduced, and enterprises will have to pay more economic costs.

- Q:What kind of products are metallurgical equipment in iron and steel works?

- At present, the slab caster is the main equipment in large iron and steel plant, and the most advanced smelting rolling equipment at present.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cored Wire Feeding Machine for Metallurgy Industry(4 wires)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords