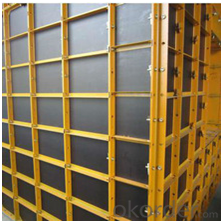

Concrete plywood formwork system Concrete plywood formwork system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

advantages

1.Lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. it is more available with high-rise building and bridge construction.

2.Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant.

3.Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. Corrosion resistance: not pollute the concrete surface.

4.Coating the film faced plywood with high-quality import films ensures hardness and damage resistance. The surface of the film faced plywood is hygienic and resistant to strong

detergents, which is important for farming constructions and storage of food products.

5.It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites. Heat preservation performance is good, be helpful for winter construction. You don’t need to worry about the quality.

- Q: Can polyurethane sandwich panels be used for cold storage?

- Yes. Polyurethane cold storage board is a good insulation of lightweight polyurethane as the inner material, the external by the SII, PVC color steel plate and stainless steel plate made of polyurethane sandwich panels, the advantage of doing so is to prevent cold storage board because of the large temperature difference between inside and outside The temperature of the spread, so that the cold storage more energy-efficient, improve the efficiency of cold storage. Luoyang Tianjiang chemical production of polyurethane cold storage board also has fire, flame retardant and high temperature and other excellent features.

- Q: Suzhou Yanmian sandwich board which is good?

- It is recommended to consider Suzhou Fu new purification equipment Technology Co., Ltd., the company is specialized in the purification equipment R & D and production, purification engineering design, purification engineering construction, purification project maintenance clean room vacuum cleaner, laminar flow hood FFU, clean shed and electrostatic products sales Comprehensive technical services of high-tech enterprises. It can provide professional air purification system engineering design for air electronics, biomedical, hospital operating room, fiber optic cable, food and beverage, precision instrument, semiconductor and new material application, air purification system engineering, air purification system engineering inspection and air Purification system engineering and technical services; according to the customer's actual requirements and the actual needs of the design, manufacture, installation of clean room systems and equipment. So you can consider buying and cooperating.

- Q: Fire protection recommendations for color steel sandwich panels

- Color plate can fire from six aspects: First, the use of good fire performance rock wool as a core material, which is a permanent solution. Second, in the process of building, the core material to stay away from welding, gas welding and other fire operations; Third, in the course of the use of some heat, the fire should not be next to the steel plate, to maintain a certain distance. If you want to set the kitchen in the color steel room, you need to have insulation layer, the wall should be installed fireproof rock insulation layer; Fourth, the wire, the cable is best not to pass from the core material, if necessary to wear protective cover Tube, socket, switch box should be used metal galvanized box and the use of mounted method; Fifth, indoor and outdoor with a simple fire fighting equipment, conditional installation of fire alarm should be convenient to facilitate the rapid evacuation of personnel; At least 6 meters to maintain a safe distance. Insulating materials that are not strictly flame-retardant are not flammable but are self-igniting. Strict, scientific and effective management, so that the fire away from the flammable color steel plate sandwich filler material, is to prevent color steel room fire is one of the important ways.

- Q: 2x8 foor joists above not supporting the roof

- Nope! You'll have to use a double 1 3/4 x 14 LVL. The best you can do with a double 2 x 12 is between 6' 3 and 8' 1 depending on the width of the building parallel to the joists.

- Q: Rock wool sandwich panels and polyurethane sandwich panels which high fire rating

- Of course, is the rock wool composite board, and fire rating can reach A level, polyurethane sandwich panels can only reach B level, there is a new type of rock wool sandwich panels, is the use of external wall insulation fire isolation belt principle, to achieve the same Fire protection effect, but the cost is greatly reduced, the weight of ultra-light, is the ideal steel supporting color steel sandwich panels, has applied for national patents, Shandong Zibo permanent color steel tile company production, welcomed by users, is the traditional color steel rock wool Sandwich panels to upgrade products, users are welcome to visit, purchase.

- Q: Is the factory wall with a sandwich board fire clearance?

- The first look at the factory declaration materials in the building level. The second depends on the material you use sandwich panels. (Generally Caigang sandwich rock wool no problem, glass wool depends on the design requirements of the building).

- Q: Does anyone know the reason why the sandwich panel is bubbling and partially degumming during the pressing process?

- Hydraulic press to suppress the plate, the bubble and local degumming these two phenomena are due to: 1, veneer moisture content is too high or dry uneven 2, the amount of glue is too large 3, buck faster or hot pressing temperature is too high 4, the degree of condensation is not enough resin 5, hot pressing time is insufficient

- Q: Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Roof 75 stupid 135 self-tapping nail 100 stupid 165 self-tapping nail wall 50 stupid 75 self-tapping nail 75 stupid 100 self-tapping nail 100 stupid 125 tapping nail

- Q: To do color steel sandwich panels.

- Now is the best in Sichuan

- Q: What color steel sandwich panels are used in hospital laboratories

- Need to look at a specific situation.

Send your message to us

Concrete plywood formwork system Concrete plywood formwork system

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords