Aca Aluminum Coil Anodizing Corp Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

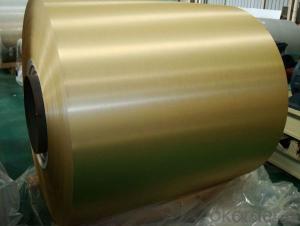

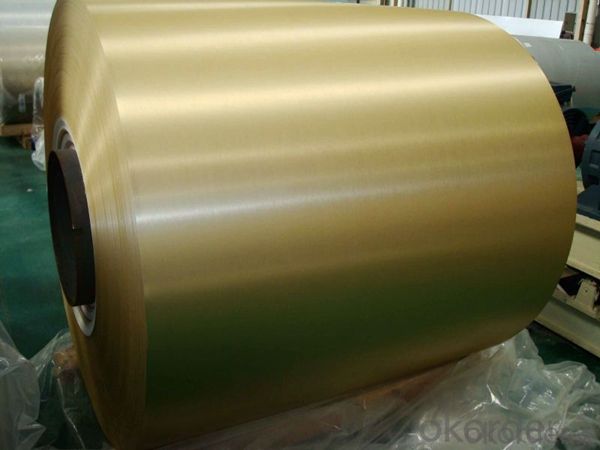

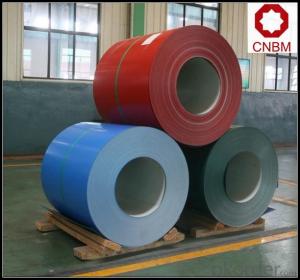

5. Image of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

6. Package and shipping of Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to reduced material waste?

- There are several ways in which aluminum coils contribute to the reduction of material waste. Firstly, aluminum is a material that can be recycled multiple times without losing its properties. This recyclability feature alone helps to reduce material waste as it eliminates the need for extracting and producing new aluminum. Moreover, industries that require precision and efficiency, such as automobile manufacturing, HVAC systems, and electrical equipment, often utilize aluminum coils. These coils can be easily tailored to meet specific requirements, minimizing the use of excess material and reducing waste. Furthermore, aluminum coils have a high strength-to-weight ratio, meaning they can be manufactured using less material while still maintaining the desired strength and durability. This lightweight characteristic not only reduces material waste but also allows for more efficient transportation and installation processes, resulting in lower fuel consumption and less environmental impact. In addition, aluminum coils can be designed to have a longer lifespan and improved resistance to corrosion. This durability factor helps to minimize the need for frequent replacement, thereby reducing material waste over time. Furthermore, the long lifespan of aluminum coils makes them an appealing choice for sustainable construction practices, further contributing to waste reduction in the long term. Overall, the utilization of aluminum coils in various industries not only promotes recycling and reusability but also enables efficient customization, lightweight construction, enhanced durability, and extended lifespan. These factors collectively contribute to the reduction of material waste, making aluminum coils an environmentally-friendly option.

- Q: This question seeks to understand the environmental impact of discarded aluminum coils.

- <p>Discarded aluminum coils can have significant environmental impacts. They contribute to landfill waste and can potentially leach harmful substances into the soil and water if not properly managed. Aluminum production is energy-intensive, so recycling discarded coils reduces the demand for raw materials and conserves energy. However, if left in the environment, aluminum can also contribute to pollution and disrupt ecosystems. Proper recycling and disposal methods are crucial to mitigate these effects and promote sustainability.</p>

- Q: Explain the key differences between aluminum coil welding and soldering processes.

- <p>Aluminum coil welding and soldering are two distinct methods used in metal joining. Welding involves the fusion of aluminum coils using heat to create a strong bond between the metals. This process can be done with various techniques such as MIG, TIG, or laser welding, and it results in a permanent joint. Soldering, on the other hand, is a process that uses a filler metal with a lower melting point than the base metal (aluminum in this case) to join the materials. The joint is not as strong as a welded joint, and the process does not involve melting the base metal. Soldering is often used for electrical connections or when a less permanent bond is required. In summary, welding creates a stronger, more permanent bond by melting the base metal, while soldering uses a filler metal to create a less permanent bond.</p>

- Q: Can aluminum coils be used for food storage and processing?

- Food storage and processing can indeed utilize aluminum coils. The multitude of advantageous properties that aluminum possesses is what makes it a popular choice in this field. Its lightweight nature, strength, and resistance to corrosion create an ideal environment for maintaining the quality and freshness of food. Aluminum coils are versatile and can be used to manufacture a wide range of equipment like containers, pans, trays, and foil for food storage and processing. Additionally, the excellent thermal conductivity of aluminum enables efficient cooling and heating of food. Its impermeability to light, moisture, and oxygen is also beneficial in preventing spoilage and contamination. In conclusion, aluminum coils offer a reliable and secure option for food storage and processing needs.

- Q: Explain how aluminum coils are connected to electronics.

- <p>Aluminum coils play a significant role in the electronics industry due to their high electrical conductivity and low density. They are used in various components such as transformers, inductors, and chokes, where they help in the conversion and regulation of electrical energy. Aluminum's non-magnetic properties make it ideal for parts that need to be shielded from magnetic fields. Additionally, aluminum coils are used in heat sinks to dissipate heat generated by electronic devices, ensuring their efficient operation and longevity.</p>

- Q: What are the weight and length specifications of aluminum coils?

- The weight and length specifications of aluminum coils can vary depending on the specific application and industry requirements. However, typically aluminum coils can range in weight from a few hundred pounds to several thousand pounds, and in length from a few feet to hundreds of feet.

- Q: Is it possible to utilize aluminum coils in the packaging of food products?

- <p>Yes, aluminum coils can be used for food packaging. They are commonly used in the production of aluminum foil, which is a popular material for food packaging due to its properties such as light weight, barrier to light and oxygen, and recyclability. Aluminum foil is used to wrap food, line baking sheets, and create containers, providing a protective barrier that helps to preserve freshness and extend shelf life. However, it's important to ensure that the aluminum used meets food-grade standards to avoid any health risks.</p>

- Q: Can aluminum coils be utilized in the process of welding?

- <p>Yes, aluminum coils can be used for welding work. They are commonly used as filler material in processes like MIG (Metal Inert Gas) welding. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need for shielding from oxidation. The aluminum coils must be of good quality and compatible with the welding process to ensure a strong and durable weld. Proper selection of welding parameters, such as amperage and voltage, is crucial for successful aluminum welding.</p>

- Q: What are the common coil inner diameters for aluminum coils?

- The specific application and industry requirements can cause the common coil inner diameters for aluminum coils to vary. Nonetheless, 150 mm (5.9 inches), 200 mm (7.9 inches), and 300 mm (11.8 inches) are frequently utilized inner diameters for aluminum coils. These inner diameters are often selected considering factors like the coil's size, weight, ease of handling, and compatibility with manufacturing equipment. It is crucial to acknowledge that these examples are merely a few, and the actual inner diameters may differ based on the unique needs of each industry or application.

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

Aca Aluminum Coil Anodizing Corp Color Coating Aluminum Coil Rolled AA1100, 3003, 3004, 5182, 5052, 8011

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords