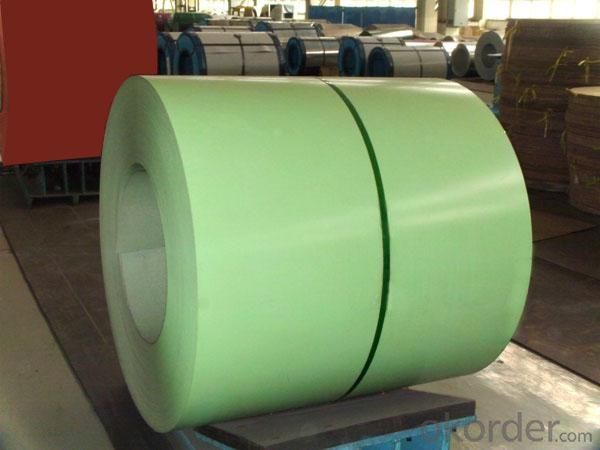

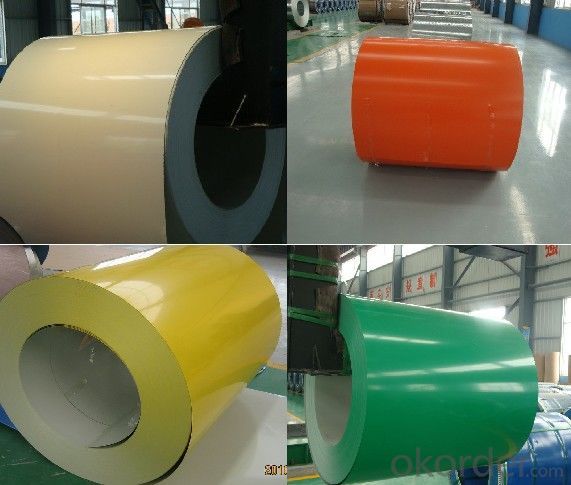

Color Coated Steel Sheet 2015 Best Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2900 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Color Coated Steel Sheet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Color Coated Steel Sheet is ideal for general fabricating and metalworking.

Product Advantages:

OKorder's Steel Sheet is durable, resists corrosion, and are conducive to processing, such as PPGI embossing, printing, and punching.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-30 days after receiving deposit)

· Corrosion resistance

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195, SGCC, SGCD, SECC, SECD, DX51D+Z

Height: 90 – 400mm

Width: 600 – 1250mm

Thickness: 0.16 – 2.0mm

Length: As per customer request

Coating: 80 – 275g/m² Zn

Surface: Galvanized, zero spangle, regular spangle, normal spangle

Treatment: Chromated & oiled, chromated, non-oiled

Packaging: Standard export packing, 4 steel eye bands and 4 steel circumferential bands, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- Yes it is possible to recover individual elements from an alloy such as stainless steel, but not easy. Look up etching of stainless steel on google. This same etching solution will completely dissolve stainless steel. These solutions are strong acids such as H2SO4 and HNO3 so safety goggles and good ventilation are absolutely required. Once the metal has been dissolved, then you would need to use a qualitative analysis scheme to precipitate out the different metals one at a time as compounds, then do additional reactions to recover the metallic elements.

- Q: What are the environmental considerations of using steel coils?

- There are several environmental considerations associated with using steel coils. Firstly, the production of steel coils involves a significant amount of energy and resources. Steel production is a carbon-intensive process, contributing to greenhouse gas emissions, particularly from the use of fossil fuels in the manufacturing process. The extraction and processing of iron ore to produce steel coils also require extensive mining activities, which can lead to habitat destruction and soil erosion. Additionally, the transportation of steel coils can have environmental impacts. Steel coils are generally heavy and bulky, requiring large vehicles for transportation. This can result in increased carbon emissions and air pollution due to the use of fossil fuel-powered transportation methods. Furthermore, the disposal or recycling of steel coils can pose environmental challenges. If steel coils are not properly managed after use, they can end up in landfills or incinerators, contributing to waste generation and potential pollution. However, steel is a highly recyclable material, and by implementing effective recycling practices, the environmental impact of steel coil disposal can be minimized. Lastly, the use of steel coils in construction and manufacturing industries can have indirect environmental impacts. Steel coils are commonly used in the construction of buildings and infrastructure, which can result in deforestation and habitat loss due to land clearing. Moreover, the manufacturing processes that utilize steel coils may generate waste, pollutants, and emissions that can harm ecosystems and human health if not properly regulated and managed. To mitigate the environmental considerations associated with using steel coils, various measures can be taken. These include implementing energy-efficient technologies and practices in steel production, promoting sustainable mining practices, optimizing transportation logistics to reduce emissions, encouraging responsible disposal and recycling of steel coils, and promoting the use of alternative materials or steel products with a lower environmental footprint, such as recycled steel or steel with a higher proportion of recycled content.

- Q: How do steel coils contribute to the automotive industry?

- The automotive industry heavily relies on steel coils to manufacture different components and structures for vehicles. These coils are made from high-quality steel and undergo a series of processes, such as hot rolling, cold rolling, and annealing, to achieve the desired properties. One of the main applications of steel coils in the automotive industry is for producing body panels and frames. The strength and durability of steel make it an ideal material for these purposes, providing structural integrity and protection to the vehicle. Through a stamping process, steel coils are transformed into sheets, allowing manufacturers to create intricate shapes and designs for various vehicle models. Furthermore, steel coils are also utilized in the production of suspension systems, including springs and shock absorbers. The elasticity and resilience of steel enable these components to withstand the constant impact and weight of the vehicle, ensuring optimal performance and comfort for the driver and passengers. In addition, engine components like crankshafts, camshafts, and cylinder heads are manufactured using steel coils. These components require the strength and thermal resistance that steel provides, ensuring the efficient operation and longevity of the engine. Moreover, steel coils play a crucial role in the production of exhaust systems, which are essential for reducing emissions and noise levels. Steel's resistance to heat and corrosion make it an excellent material choice for exhaust pipes, mufflers, and catalytic converters, ensuring their durability and functionality. Overall, steel coils are indispensable in the automotive industry as they contribute to the manufacturing of various components and structures that are vital for the performance, safety, and longevity of vehicles. The high strength, durability, and versatility of steel make it the preferred material choice, enabling manufacturers to create reliable and efficient automobiles.

- Q: Can steel coils be cut to length?

- Yes, steel coils can be cut to length.

- Q: They say it's some six times stronger than steel. need some explanation.

- Lol I dont know where you heard that, there probably saying for small insects like for instence a small instect in a spider web is like us( humans ) in steel but no I could break through a web with my soft hair or finger, like not an ant because there extremely strong but like a flea

- Q: Can steel coils be used in corrosive environments?

- Yes, steel coils can be used in corrosive environments. However, it is important to select the appropriate type of steel and implement suitable protective measures such as coatings or galvanization to prevent corrosion.

- Q: Which is used for what?Differences as far as style etc.???Better in your opinion and why??I'm just beginning to look at guitars i might be able to get at christmas if i'm still committed..i've been looking online.,,,,NYLON or STEEL STRINGED ACOUSTIC GUITAR????Thanks.

- Nylon stringed guitars are almost always intended for classical and flamenco guitar styles. You might see the occasional performer using one for folk, and of course Willie Nelson is famous for his nylon string sound in the country genre. The strings can be easier on a beginners fingers but you will find much less selection than with steel string guitars. Nylon has a mellower sound than steel, and good ones sound amazingly rich and full. Classical guitarists use their fingernails instead of picks to get more varied texture out of the guitar, but you can safely use a pick. Steel stringed guitars are what you are seeing and hearing most if you listen to pop, rock, country, folk, etc. There will be a much wider selection of beginner instruments to choose from. ( and some of them will be horrible!) The strings can be tougher on your fingers until you build up callouses, but that only takes a month or so. A steel string guitar will sound correct in a wider range of music, but will never sound as good at classical music as nylon. Bottom line: you can learn on either style guitar, but unless you are planning to go into classical or flamenco guitar, go with steel. In either case, don't get the cheapest one out there. It's a real case of you-get-what-you-pay-for. A cheap one will be harder to play and keep in tune.

- Q: How are steel coils inspected for elongation?

- Elongation inspections of steel coils involve various methods. One commonly used technique entails employing a tensile testing machine. This method entails extracting a small sample from the steel coil and inserting it into the machine. Subsequently, the machine exerts a pulling force on the sample until it fractures. The force required to cause the sample to break is measured, and this data is utilized to determine the elongation of the steel coil. Ultrasonic testing represents another approach adopted to inspect steel coils for elongation. In this method, high-frequency sound waves are transmitted through the steel coil. Through the analysis of the sound wave reflections, it becomes feasible to ascertain the elongation and other characteristics of the steel coil. Visual inspection also holds significant importance in the examination of steel coils for elongation. Trained technicians visually scrutinize the steel coils for any indications of stretching or deformation, which may indicate excessive elongation. In conclusion, a comprehensive inspection of steel coils for elongation and adherence to industry standards entails a combination of mechanical testing, ultrasonic testing, and visual inspection. This approach ensures the quality and compliance of the steel coils.

- Q: What are the major challenges faced by steel coil manufacturers?

- Some major challenges faced by steel coil manufacturers include fluctuations in raw material prices, increasing competition from international markets, the need to meet strict quality and safety standards, and the impact of global economic conditions on demand for steel products. Additionally, environmental regulations and sustainability concerns have also become important challenges for steel coil manufacturers.

- Q: Can steel coils be stacked on top of each other?

- Yes, steel coils can be stacked on top of each other.

Send your message to us

Color Coated Steel Sheet 2015 Best Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2900 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords