Aluminum Sheets Hawaii - Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

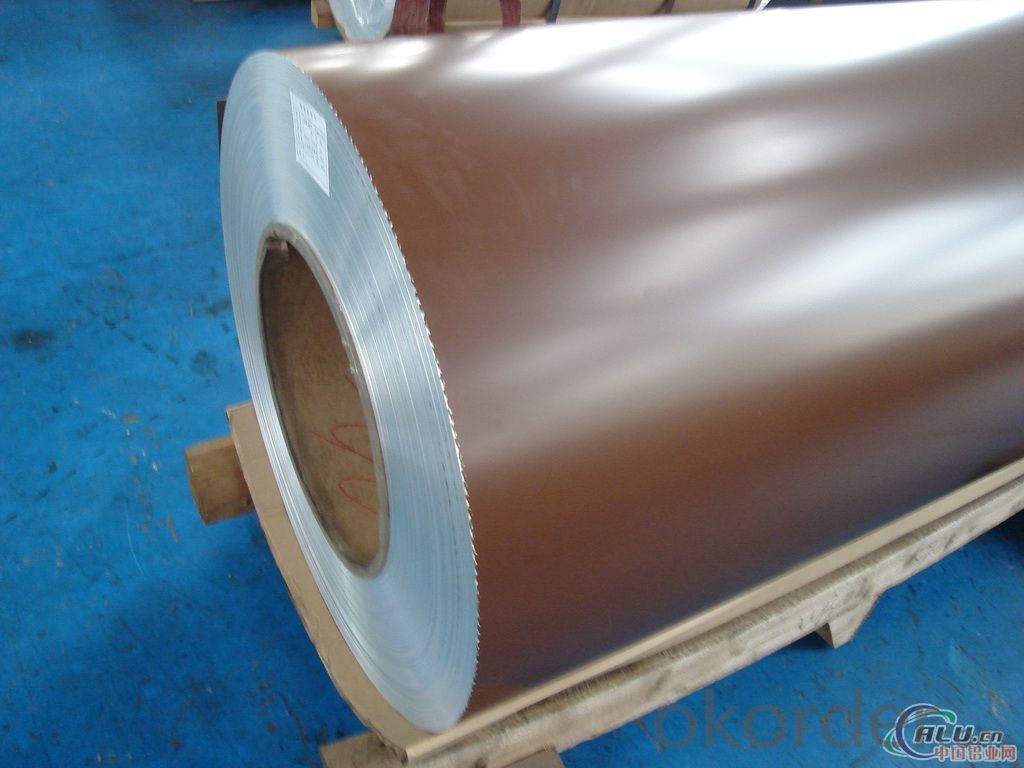

1.Structure of Color Coated Aluminium Coils

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Color Coated Aluminium Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2mm-3mm | 1200MM-1800MM | Min 5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do you store aluminum sheets?

- Aluminum sheets should be stored in a dry and well-ventilated area, preferably indoors, to prevent corrosion. They should be stacked horizontally on a flat surface, with a protective covering such as plastic or cardboard between each sheet to avoid scratches. Additionally, it is advisable to separate different gauges or alloys to avoid galvanic corrosion. Regular inspection and maintenance are essential to ensure their longevity.

- Q: What are the different edge treatments available for aluminum sheets?

- There are several different edge treatments available for aluminum sheets, each serving a specific purpose or aesthetic preference. Some common edge treatments for aluminum sheets include: 1. Mill Finish: This is the standard edge treatment for aluminum sheets, where the raw edges of the sheet are left untreated after the manufacturing process. It has a smooth, unfinished appearance. 2. Trimmed: In this treatment, the rough edges of the aluminum sheet are trimmed and smoothed to create a clean, rounded edge. This is often done using shearing or milling techniques. 3. Deburred: Deburring is a process where the sharp edges of the aluminum sheet are removed, typically by filing or sanding, to eliminate any potential hazards or sharpness. It results in a smoother, safer edge. 4. Rolled: Rolled edges are created by bending the edges of the aluminum sheet inward or outward. This treatment provides additional strength and rigidity to the sheet and can also enhance its appearance. 5. Anodized: Anodizing is a surface treatment that involves immersing the aluminum sheet in an electrolytic solution and applying an electric current. This creates a protective oxide layer on the surface, which can be colored to provide an attractive and durable edge finish. 6. Powder Coated: Powder coating involves applying a dry powder paint onto the aluminum sheet, which is then heated to form a hard, protective finish. This treatment can be used to create a variety of colors and textures for the edge. 7. Brushed: Brushed finishes are achieved by brushing the aluminum sheet with abrasive materials, creating a textured and visually appealing edge. This treatment is often used for decorative purposes. 8. Polished: Polishing involves buffing the aluminum sheet to create a smooth, reflective surface. This treatment is commonly used for architectural and decorative applications to enhance the appearance of the edge. These are just a few examples of the various edge treatments available for aluminum sheets. The choice of treatment depends on factors such as the intended use, desired aesthetics, and functional requirements of the aluminum sheet.

- Q: Can aluminum sheet be used for heat shielding?

- Yes, aluminum sheet can be used for heat shielding. Aluminum has a high thermal conductivity and excellent heat dissipation properties, making it an effective material for heat shielding applications. Its ability to reflect radiant heat also makes it suitable for use in thermal barriers and insulation systems. Additionally, aluminum sheet is lightweight, corrosion-resistant, and easily fabricated, making it a cost-effective choice for heat shielding in various industries such as aerospace, automotive, and electronics.

- Q: What are the different surface finishes for aluminum sheets in the automotive industry?

- The different surface finishes for aluminum sheets in the automotive industry include mill finish, anodized finish, and painted finish. Mill finish refers to the untreated surface of aluminum sheets, which typically has a matte appearance. Anodized finish involves an electrochemical process that creates a protective layer on the surface of aluminum, enhancing its resistance to corrosion and increasing its durability. Painted finish involves applying a layer of paint onto the aluminum sheet, providing both aesthetic appeal and additional protection against the elements.

- Q: Are aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. Aluminum is a versatile material that can be easily manipulated into various shapes and designs, making it ideal for decorative applications. It can be cut, bent, and formed into different patterns, allowing for endless possibilities in creating decorative elements. Additionally, aluminum sheets can be coated or painted in different colors and finishes to further enhance their aesthetic appeal. Furthermore, aluminum is a lightweight and durable material, which makes it suitable for both indoor and outdoor decorative use. It is resistant to corrosion, ensuring that the decorative elements made from aluminum will retain their appearance and last for a long time. Overall, aluminum sheets offer a wide range of design possibilities and practical benefits, making them an excellent choice for decorative purposes.

- Q: Which kind of glue can bond hard shell plastic and iron sheet or aluminum sheet?

- 502 or AB glue (there are two glues, they won’t bond together while separated, but the viscidity is strong after being mixed together. They usually are used for bonding cars accessories.) you can buy them in hardware shop or auto supply store.

- Q: I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- Cheers Watch this video: A little boy bites his brother's finger - His brother's reaction is hilarious! F

- Q: Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors in certain applications. Aluminum is known for its excellent corrosion resistance, which makes it suitable for various chemical reactions. However, it is important to consider the type of chemicals being used and their potential reactivity with aluminum. Aluminum may not be suitable for highly acidic or alkaline environments as it can react and corrode. Additionally, aluminum may not be appropriate for reactions involving certain gases or high temperatures. In such cases, alternative materials like stainless steel or glass-lined reactors may be more suitable.

- Q: Are aluminum sheets suitable for automotive suspension components?

- Yes, aluminum sheets are suitable for automotive suspension components. Aluminum is a lightweight and strong material, making it ideal for reducing the overall weight of the vehicle and improving fuel efficiency. Additionally, aluminum offers good corrosion resistance, which is crucial for automotive applications.

Send your message to us

Aluminum Sheets Hawaii - Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords