Aluminum Sheets in Missouri - Color Coated Aluminum Coils for Interior Decoration Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

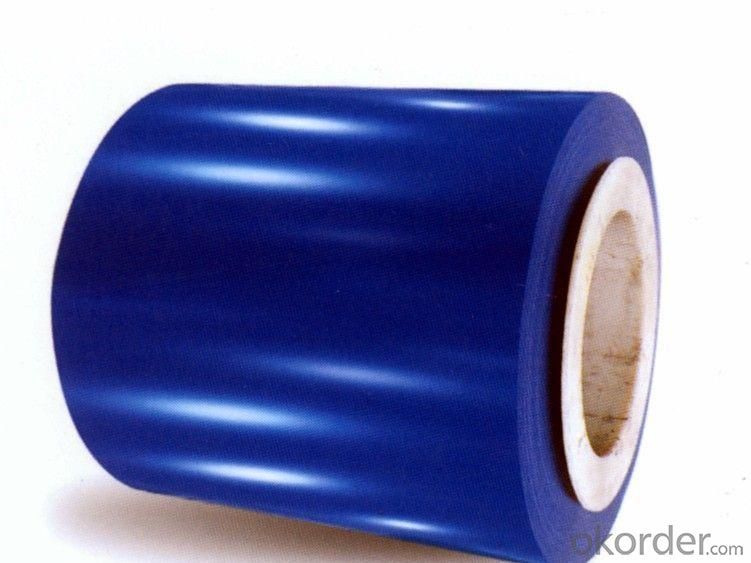

1.Structure of Color Coated Aluminium Coils for Inner Decoration Ceilling

Color Coated Aluminium Coils for Inner Decoration Ceilling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Inner Decoration Ceilling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the different types of finishes used for decorative aluminum sheet?

- There are several different types of finishes that can be used for decorative aluminum sheet to enhance its appearance and provide added protection. Some of the most common finishes include: 1. Mill finish: This is the standard finish that aluminum sheets have when they come straight from the mill. It has a smooth, shiny appearance but lacks any additional treatments or coatings. 2. Anodized finish: This finish involves an electrochemical process that creates a durable, corrosion-resistant layer on the surface of the aluminum. Anodized finishes can be clear or colored, and they provide a decorative, matte appearance. 3. Brushed finish: Also known as satin finish, this type of finish involves brushing the aluminum sheet with a fine abrasive material to create a pattern of fine lines or scratches. It gives the sheet a textured, non-reflective surface that hides any imperfections. 4. Polished finish: This finish involves polishing the aluminum sheet with a series of abrasive materials to create a smooth, reflective surface. It gives the sheet a shiny, mirror-like appearance and is often used for decorative purposes. 5. Painted finish: Aluminum sheets can also be painted with various types of coatings to provide different colors and finishes. These coatings can be applied through techniques such as powder coating, liquid painting, or coil coating, and they offer both decorative and protective benefits. 6. Embossed finish: In this type of finish, the aluminum sheet is pressed with a pattern or design to create a three-dimensional surface. Embossed finishes can vary in depth and detail, and they add texture and visual interest to the sheet. These are just a few examples of the different types of finishes used for decorative aluminum sheet. Each finish offers its own unique look and benefits, allowing for a wide range of design possibilities.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- Don't eat the foil. The only potentially direct connection to Alzheimers with aluminum was where aluminum dust was inhaled in an industrial setting over several years and the person was diagnosed with Alzheimer's and had high amounts of neurotoxic aluminum in his brain.

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: Are 101 aluminum sheets suitable for chemical processing equipment?

- 101 aluminum sheets are not suitable for chemical processing equipment. While aluminum is a versatile and widely used material, it is not recommended for applications involving strong acids or bases. Aluminum is susceptible to corrosion when exposed to certain chemicals, and this can compromise the integrity of the equipment and potentially lead to leaks or other safety hazards. For chemical processing equipment, it is advisable to choose materials that are specifically designed and manufactured to withstand the corrosive effects of the chemicals being used.

- Q: Are 101 aluminum sheets suitable for interior design or architectural applications?

- Yes, 101 aluminum sheets are suitable for interior design or architectural applications. They are commonly used due to their lightweight nature, durability, and corrosion resistance. Additionally, they can be easily formed into various shapes and sizes, making them versatile for different design purposes.

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is generally considered to be excellent. Aluminum is a highly malleable metal, meaning it can be easily shaped or formed into various designs without cracking or breaking. This characteristic makes aluminum sheets highly desirable for a wide range of applications, including automotive body panels, aircraft components, and household appliances. Additionally, aluminum has good ductility, which allows it to be stretched and bent without losing its structural integrity. However, it is important to note that the formability of aluminum sheets can vary depending on the alloy composition, thickness, and processing conditions. Therefore, it is essential to consider these factors when choosing the appropriate aluminum sheet for a specific application.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Can 101 aluminum sheets be recycled?

- Yes, 101 aluminum sheets can be recycled. Aluminum is highly recyclable, and the recycling process for aluminum is quite efficient. By recycling aluminum sheets, valuable resources can be conserved, energy can be saved, and greenhouse gas emissions can be reduced. Recycling aluminum also helps in reducing landfill waste and the need for mining new aluminum ores. Therefore, it is recommended to recycle 101 aluminum sheets to contribute to a more sustainable and environmentally friendly future.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

- Q: What is the elongation of aluminum sheets?

- The elongation of aluminum sheets refers to the amount of stretch or deformation that the sheets can undergo before breaking or tearing. It is a measure of the material's ductility or ability to be elongated without fracturing. The elongation of aluminum sheets can vary depending on factors such as the alloy composition, tempering, and processing techniques used during manufacturing. Generally, aluminum sheets have a high elongation percentage, ranging from 15% to 40%. This means that they can be bent, formed, or stretched to a certain extent without losing their structural integrity. The elongation of aluminum sheets is an important property to consider in applications where the material needs to withstand deformation or be shaped into complex forms.

Send your message to us

Aluminum Sheets in Missouri - Color Coated Aluminum Coils for Interior Decoration Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords