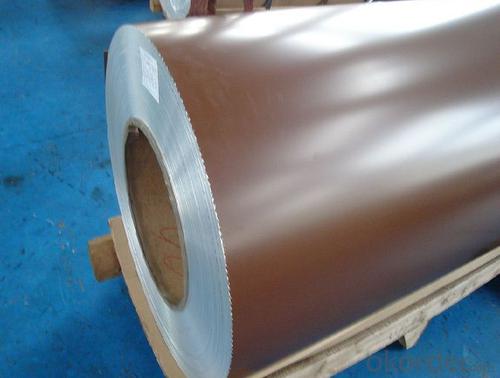

Rustic Red Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Aluminium Coil for Decoration

l Product Description

1 Building outer wall, curtain wallboard, airport, railway station, ect.

2 The old buildings renovation

3 Equipment unit, indoor compartment

4 Billboard, identification board, advertising signboard

5 Install the panel, show stand shelf inside

6 Industrial material protecting the car body of the old car

7 Other place that you want to use

Feature:

1 Light weight and easy to process

2 High peeling strength

3 Super weather resistance

4 Even coating and multiple colors

5 Excellent impact resistance

6 Excellent fireproof feature

7 Easy to maintain

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Are aluminum coils suitable for architectural cladding applications?

- Aluminum coils, indeed, are well-suited for architectural cladding applications. The versatility of aluminum as a material offers a multitude of advantages when it comes to cladding purposes. To begin with, aluminum's lightweight properties make it effortlessly manageable and installable. This not only lessens the burden on the building structure but also simplifies the construction process as a whole. Moreover, aluminum exhibits exceptional durability and resistance against corrosion. Consequently, it becomes an ideal selection for exterior applications, withstanding even the harshest of weather conditions while preserving its appearance over time. In addition to its durability, aluminum coils possess the ability to be fabricated into various shapes and sizes, allowing for a flexible design approach. They can be effortlessly formed, cut, and molded to precisely meet the specific requirements of any given building project. Architects and designers also benefit from the wide range of finishes and colors available in aluminum. This provides them with ample options to achieve the desired aesthetic for the cladding. Furthermore, opting for aluminum aligns with the growing emphasis on environmentally friendly construction practices, as it is entirely recyclable. Overall, the myriad of advantages, including versatility, durability, lightweight nature, aesthetic options, and sustainability, make aluminum coils a fitting choice for architectural cladding applications.

- Q: We had a BBQ a few days ago and left our pack of aluminum foil on the table out side. It rained that night and the following night. I went out to take the trash out and heard a odd noise. It was the pack of foil boiling hot. The water from the rain was steaming out of it. When I picked it up you could feel the warmth coming from the center of it.It was 2 days after the BBQ, was never near the heat of that. It was on a separate table.The table is shaded all day, so it didn't heat from the sun. Plus aluminum does not transfer heat.It just don't make since to me. I unrolled some of it and it is dark grey from being heated so hot. I never heard of it and tried to find info, but to no avail. So out of curiosity I am asking.

- Aluminum does not go wel in heat, in fact if left under extreme heat + pressure (A.K.A.) microwave, or toast oven, it will explode, there will be nothing left but tiny fragments of aluminum tinfoil.

- Q: How do aluminum coils contribute to energy-efficient HVAC systems?

- The role of aluminum coils in making HVAC systems energy-efficient is crucial. Firstly, aluminum is an exceptional heat conductor, enabling efficient heat transfer between different areas. In HVAC systems, aluminum coils are utilized in the condenser and evaporator units to facilitate the heat exchange process. In the condenser unit, the hot refrigerant vapor from the compressor passes through the aluminum coils. Due to the coils' high thermal conductivity, the heat is rapidly dissipated to the surrounding air, allowing the refrigerant to condense and release the heat energy. This effective heat transfer enhances the cooling performance of the HVAC system. Similarly, in the evaporator unit, the aluminum coils are responsible for absorbing heat from the indoor air. The cold refrigerant inside the coils absorbs the heat, resulting in the air cooling down. Ultimately, the cooled air is circulated back into the room. The superior thermal conductivity of aluminum enables quick heat absorption, improving the overall cooling efficiency of the HVAC system. Moreover, aluminum coils offer an energy-saving advantage by being lightweight. Compared to traditional copper coils, aluminum coils reduce the overall weight of the HVAC system. This weight reduction leads to lower energy consumption by the system's fan and compressor, as they require less effort to move the air and refrigerant throughout the system. Additionally, aluminum coils are highly resistant to corrosion, which prolongs the lifespan of the HVAC system. Corrosion can hinder heat transfer efficiency and result in refrigerant leaks, causing the system to consume more energy. By utilizing aluminum coils, the risk of corrosion is minimized, ensuring long-term energy efficiency. In conclusion, aluminum coils enhance the energy efficiency of HVAC systems by improving heat transfer efficiency, reducing overall system weight, and providing corrosion resistance. These factors collectively contribute to the effective operation of HVAC systems, consuming less energy while maintaining optimal indoor comfort.

- Q: Can aluminum coils be used in heat exchangers?

- Yes, aluminum coils can be used in heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The high thermal conductivity of aluminum allows for efficient heat transfer, making it an ideal material for heat exchangers. Additionally, aluminum's corrosion resistance ensures that the coils will remain durable and functional even in harsh environments.

- Q: Will the surface of the aluminum sheet touch the water?Aluminum rolls weighing 3.463 tons,.35mm thick, 900mm wide, very tight coil, is a mechanical binding. Water does not penetrate the surface of aluminium rolls

- Do you want to ask if the water has seeped into the crevice?If you get it soon, there should be no problem. No, you can just sun it and see if there's any water coming out of it

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

- Q: Can aluminum coils be embossed or textured?

- Yes, aluminum coils can be embossed or textured. This process involves creating patterns or designs on the surface of the aluminum coils using specialized equipment and techniques.

- Q: Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q: What are the safety regulations that need to be followed while using aluminum coil?

- <p>Yes, there are safety regulations for using aluminum coil. These include ensuring proper ventilation to prevent the buildup of aluminum dust, which can be a fire hazard. Protective equipment such as gloves and eyewear should be worn to avoid skin and eye contact with the material. Additionally, it's crucial to follow guidelines for handling and storing aluminum coils to prevent accidents, such as ensuring they are not damaged or exposed to extreme temperatures. Compliance with local and industry-specific safety standards is also essential to maintain a safe working environment.</p>

Send your message to us

Rustic Red Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords