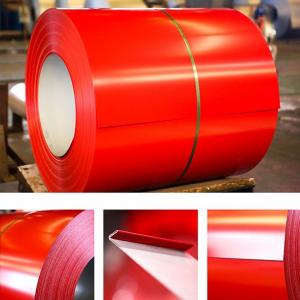

Color Coated Alu-zinc Steel Coil PPGP for buildings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGCD1,SGCD2.SGCD3,SGC340, | Thickness: | 0.17-2.0mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | SGCC,SGCD1,SGCD2.SGCD3,SGC340, | |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | coil |

Packaging & Delivery

| Packaging Detail: | standard sea-worthy packaging or as buyers' requirement. |

| Delivery Detail: | Within 20-30 days after we receive depoist or L/C at sight |

color coated steel coil

Product Description

Company | CNBM |

Product | color coated steel coil |

Port | Shang Hai China |

Thickness | 0.17-2.0mm |

Width | 600-1250mm |

Material Grade | SGCC,SGCH,SGCD1-SGCD3,DX51D |

Technique | cold rolled |

Standard | ASTM,GB ,AISI,JIS,EN |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Application | Widely used for roofs, outer walls, ovens, explosive-proof steel, electrically controlled cabinets,galvanized tube/pipe, ceiling channel, building material |

Surface | coated |

Package | standard sea-worthy packaging or as buyers' requirement. |

MOQ | 20 tons |

Payment | L/C,T/T |

Delivery time | According to The Specifications And the Quantities,Time Begin When We confirm the Date of the Earnest or L/C. |

Our Services

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

- Q: How does coil slitting work?

- Coil slitting is a process used in metalworking to cut large coils of material, such as steel or aluminum, into narrower strips. It involves feeding the coil through a set of circular knives or rotary slitters that cut the material into desired widths. The slitting process can be adjusted to achieve precise measurements, and the resulting strips are typically rewound onto separate coils or spools. Coil slitting is commonly used in various industries, including automotive, construction, and manufacturing, to obtain narrower strips that can be further processed or used as raw material for different applications.

- Q: Is steel case ammo going to mess the gun up or is it just going to wear the parts out faster and if so how much faster? (I am not planning on reloading the rounds)

- The ak was designed with the steel cased ammo in mind. The only real wear is going to be the chamber area, and even at that, it is going to take many thousands of rounds to wear it out. be more concerned with the corroive ammo, and clean the firearm well with warm soapy water or military bore cleaner after each shooting session.

- Q: I wanna strip down my bike and take off all the paint... im thinking of leaving it just the steal color... Do i need to put anythinng on the steel to coat it or can i just leave it like that... Will it rust or anything?

- If it's stainless steel or aluminum, it won't rust. Chances are the bike parts that have been painted are of metals that will rust. If you like the metal color, then you can get paints that look like metal or you can clear coat it. You might want to consider just a grey primer.

- Q: At what temperature does steel start to warp or soften.

- Just okorder

- Q: what is the difference between stainless steel 304 (AISI 304) and stainless steel 310 (AISI 310) COR-TEN A

- Weathering steel will rust, but the rust will be adherant and not flake off and be replaced by new rust. Therefore once it rusts it will pretty much stop rusting any more. One (severe) down side is that anything around it will be streaked with rust stains and it will look awful. Some bozo with the Texas Department of Transportation designed a number of freeway interchange overpasses here in Houston using Cor-Ten steel and all of the concrete supports are streaked with red rust stains and it looks like hell. Cameron built an office building here in Houston with a Cor-Ten facade and it is streaked with rust too. They should have gone ahead and spent the money and painted them, but they didn't.

- Q: What are the common surface treatments for steel coils?

- Common surface treatments for steel coils include galvanizing, which involves applying a layer of zinc to protect against corrosion; painting, where a layer of paint is applied for aesthetic purposes or to provide additional protection; and chromating, which involves applying a thin layer of chromium to enhance corrosion resistance and improve paint adhesion.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- the stuff is pretty strong... i have a friend who blew a hole in his crankcase of his 07 cr450f and used jb weld on it... added oil and rode on it.. the stuff is crazy strong just give it a day to dry

- Q: What are the common methods of inspecting steel coils for defects?

- There are several common methods used for inspecting steel coils for defects. These methods include visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Visual inspection is the most basic method and involves physically examining the surface of the steel coil for any visible defects such as cracks, dents, or surface irregularities. This method is usually the first step in the inspection process and can quickly identify any obvious defects. Ultrasonic testing is a more advanced method that uses high-frequency sound waves to detect defects within the steel coil. A probe is used to transmit ultrasonic waves into the coil, and any internal flaws or defects will reflect the sound waves back to the probe. This method is effective for detecting defects such as voids, cracks, or inclusions within the material. Magnetic particle inspection is another commonly used method for inspecting steel coils. This technique involves magnetizing the coil and then applying iron particles to the surface. Any defects or cracks will cause a disturbance in the magnetic field, attracting the iron particles and making them visible. This method is particularly effective for detecting surface cracks or defects. Eddy current testing is a non-destructive method that uses electromagnetic induction to detect defects in the steel coil. A probe is used to generate an alternating magnetic field, and any changes in the electrical conductivity or magnetic permeability of the material due to defects will produce eddy currents. These eddy currents can be measured and analyzed to identify defects such as cracks, voids, or changes in material properties. Overall, these common methods of inspecting steel coils for defects provide various levels of accuracy and sensitivity, allowing for thorough inspections to ensure the quality and integrity of the steel coils. The choice of method depends on factors such as the type and size of defects to be detected, the required level of inspection accuracy, and the cost and time constraints of the inspection process.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include an increased focus on sustainability and environmental impact, the adoption of advanced technologies for improved efficiency and productivity, growing demand for high-strength and lightweight steel coils for automotive and construction sectors, and the emergence of new markets in developing countries. Additionally, there is a shift towards digitalization and automation in order to streamline operations and reduce costs.

- Q: How are steel coils protected from mechanical damage?

- Steel coils are protected from mechanical damage through various methods such as using protective packaging materials like wooden crates or metal bands, applying plastic or paper interleaving, and utilizing specialized handling equipment during transportation and storage.

Send your message to us

Color Coated Alu-zinc Steel Coil PPGP for buildings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords