Coil steel cold rolled top selling products

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56843 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The raw material of cold rolled steel coil/sheet is high quality hot rolled product. Cold rolled steel coil/sheet as defined

in the EN 10130/98 standard, with guaranteed maximum mechanical characteristics and guaranteed minimum ductility and formability.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended

for indoor use.

Typical Applications for Cold Rolled Steel

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles - exposed as

well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing

products, unexposed construction products, as well as many other areas of manufacturing.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

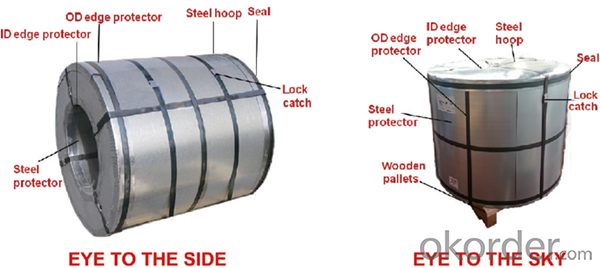

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- Carbon fiber doesn't really refer to a single material (steel doesn't either, but most steels have similar densities). Pure carbon fiber is just that, fibers made of 90+% carbon. Carbon fiber in the context of cars usually refers to carbon fiber-reinforced polymers rather than plain woven fibers. The polymer adds rigidity to what would otherwise just be like a sheet of fabric. The density depends on the polymer used and the ratio of polymer:fiber. For 50% fiber by volume in epoxy, it has a density of 1.6 g/cm^3. Steel has a density of ~7.8 g/cm^3. So, by volume, steel is almost 5 times heavier.

- Q: What are the different types of edge treatments for steel coils?

- Steel coils can undergo different edge treatments, each serving a specific purpose and offering unique benefits. 1. The most commonly used edge treatment is the slit edge. This involves cutting the coil along its width, resulting in two distinct edges. Slit edges are usually smooth and free from burrs, making them suitable for most applications. 2. The mill edge is the untreated edge of a steel coil straight from the rolling mill. It has a rough and uneven surface with visible imperfections like burrs and irregularities. Mill edges are generally not suitable for direct use and require further processing or trimming to achieve the desired edge quality. 3. The trimmed edge is a treatment that involves removing the rough and irregular portions of the mill edge. This is done through shearing or cutting, resulting in a smoother and more consistent edge. Trimmed edges are commonly used when a clean and uniform appearance is required. 4. Deburred edge refers to the process of removing any sharp or rough edges from the steel coil. This treatment is crucial for applications where safety is a concern as it eliminates the risk of injuries from handling sharp edges. Deburred edges are achieved through grinding or filing and provide a smooth and safe edge for various applications. 5. Rounded edge is a treatment that involves rounding the sharp corners of the steel coil. This is done to prevent damage to other materials or surfaces during handling or transportation. Rounded edges reduce the risk of scratches, dents, or other forms of surface damage. 6. Beveled edge is a treatment where the edge of the steel coil is cut at an angle, typically 45 degrees. This treatment is commonly used in applications that require a tight fit or seamless joint with other components. Beveled edges allow for easier assembly and improve the overall appearance of the final product. Each of these edge treatments offers its own advantages and is chosen based on the specific requirements of the application. Choosing the right edge treatment for steel coils is crucial to ensure optimal performance, safety, and aesthetics in industries such as construction, manufacturing, automotive, and more.

- Q: hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Primary Steel Making first Iron ore Coke Lime stone are mined and then took to the steel plant and put in the top off a blast furnace and sinks down to the bottom off the blast furnace and turns into molten iron. Once this process has been done it is then transferred to a BOS (Basic Oxygen Steel Making) this is then poured from a ladle into the BOS and a Lance is inserted into the BOS and pure oxygen is blown into the BOS for about 30 min and turns into steel.

- Q: How are steel coils used in the production of marine vessels?

- Steel coils are extensively used in the production of marine vessels due to their strength, durability, and versatility. These coils are typically made of high-quality steel, which is known for its ability to withstand harsh marine environments and resist corrosion. One of the primary applications of steel coils in the production of marine vessels is for the construction of the hull. The steel coils are formed into plates, which are then welded together to create the hull structure. The strength of these coils ensures that the hull can withstand the extreme forces and pressures experienced during a vessel's operation, including rough seas and heavy cargo loads. Additionally, steel coils are used in the production of various components and fittings within a marine vessel. These coils can be shaped, cut, and formed into different parts, such as bulkheads, decks, and superstructures. The versatility of steel allows manufacturers to create complex shapes and structures that are essential for the efficient and safe operation of a marine vessel. Moreover, steel coils are also used for the fabrication of pipes and tubing systems within marine vessels. These pipes are crucial for various functions, such as transporting fluids, fuel, and ventilation throughout the vessel. The strength and corrosion resistance of steel coils ensure that these pipes can withstand the high pressures and corrosive nature of marine environments. Furthermore, steel coils are utilized in the production of marine vessel equipment, such as winches, cranes, and anchor systems. These components require a high-strength material that can withstand heavy loads and constant use. Steel coils provide the required strength and durability to ensure the reliable performance of these critical equipment. In conclusion, steel coils play a vital role in the production of marine vessels. Their strength, durability, and versatility make them an ideal material for constructing the hull, manufacturing various components, fabricating piping systems, and creating equipment. The use of steel coils ensures the safety, efficiency, and longevity of marine vessels, enabling them to navigate the challenging conditions of the open seas.

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its size, thickness, and type of steel used. Generally, a standard steel coil can weigh anywhere from a few hundred pounds to several thousand pounds.

- Q: Can anyone please tell me what is the DUCTILE TO BRITTLE TRANSITION TEMPERATURE IN STEEL LOW CARBON?Thanks.

- The temperature varies with the type of low carbon steel and how it is heat treated. Common structural steel actually have a transition temperature as defined by Charpy impact tests to be in the 50 degree range. Most low carbon steel pipe such as ASTM A53, A106 and pressure vessel plate such as A212, a515 also have 50 degree range Charpy test results. If you look at materials with fine grain such A516 plate, A300 pipe and similar materials then the transition temperature drops to around -50 degrees. The thing to remember is in addition to the transition temperature you also have to have the material at a high stress level, a stress riser such as a notch and then the sudden application of additional stress to get an actual brittle fracture failure. That is why bridges make from common structural steel don't fail at temperatures as low as -40 degrees.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- If you are changing cook ware to improve your health, don't go with non-stick, because you will eventually be ingesting all that coating. The best cookware is cast iron, and the next best is stainless steel. The idea behind this recommendation is to reduce as many stresses on your immune system, so your systems can help you heal. There may be lots of other things you can do to eliminate chemicals and toxins from your house and food, so start with one thing at a time. Get some stainless steel mixing bowls, one stainless steel pot to boil water in, and then look into eating more raw foods. Use your blender and broiler. Good luck. I believe you can heal following eliminating the toxins from your house and food.

- Q: What are the different types of steel coil finishing tools?

- In the metalworking industry, various tools are utilized to finish steel coils, resulting in enhanced appearance and functionality. Common examples of these tools include: 1. Slitting Machines: These machines effectively cut large steel coils into narrower strips by utilizing sharp circular blades. The outcome is multiple smaller coils with desired widths. 2. Levellers: Used to flatten and straighten steel coils, levellers apply pressure to ensure a perfectly flat and even coil. They are particularly beneficial when coils have undergone deformation during the manufacturing process. 3. Recoilers: After slitting or levelling, recoilers rewind steel coils into a tighter and more compact shape. This process is carried out to create coils of specific diameters or sizes. 4. Edge Trimmers: To eliminate excess or uneven edges from steel coils, edge trimmers are utilized. They efficiently remove burrs, rough edges, and any other imperfections, resulting in a clean and smooth finish. 5. Inspection Machines: These machines are employed to examine the quality of steel coils. They detect defects such as surface imperfections, scratches, or dents, ensuring that only high-quality coils are delivered to customers. 6. Coating Machines: To provide protective coatings to steel coils, coating machines are utilized. These coatings, such as paint, zinc, or other materials, prevent corrosion and enhance coil durability. 7. Packaging Machines: Packaging machines securely wrap steel coils, protecting them during transportation and storage. These machines employ plastic or metal straps, shrink wrap, or other packaging materials to ensure the coils remain intact and undamaged. Overall, these diverse steel coil finishing tools are essential in the metalworking industry, enabling manufacturers to produce high-quality and visually appealing steel coils that meet specific customer requirements.

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- Hey Ramzi, I met this chick and was wondering if you could tell me if she would make a good wife. Here's your answer: Big Blue, there are a hundred bits of information I would need, and even then there are mysterious factors that affect the outcome. So basically, I don't have the slightest idea. My answer to your question is exactly the same. Without showing exactly how the Simpson Tie is being used, there is obviously no way to know if it is suitable. Can it be tempered? Sure, but again, I give it a 99% likelihood it will not help in your application. Explain it in detail in 5 to 10 sentences. Give us diagrams and photos. If you can't or won't do that, here's Plan B. Head over to your nearest machine shop, and ask the machinist what he thinks. He will ask the probing questions to understand the needs of the part. It is likely a Simpson Tie won't do it but he is in a good position to suggest a workable approach, and then sell it to you. By the way, if this is a load-supporting member of a motorcycle or some other fast moving vehicle, be prepared to get kicked out of the machine shop. The risk of making an error is high and the outcome extremely dangerous. I would not risk a million dollar lawsuit in order to sell you a $10 part.

- Q: I need new sprockets on my GSX-R1, I've heard that alumnium sprockets wear out twice as fast as steel and the difference is not noticable

- I find it hard to imagine the weight savings would ever be noticeable enough to justify using a less durable metal. You also need to figure the time spent replacing sprockets and it's possible a worn rear would cause early wear to the chain and then to the countershaft sprocket. You can also change your gear ratio easier by going down one tooth on the front instead. You just have to work the numbers. I've found it to be a simpler way to change the performance to meet that days needs. Keep it sunny side up!

Send your message to us

Coil steel cold rolled top selling products

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56843 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords