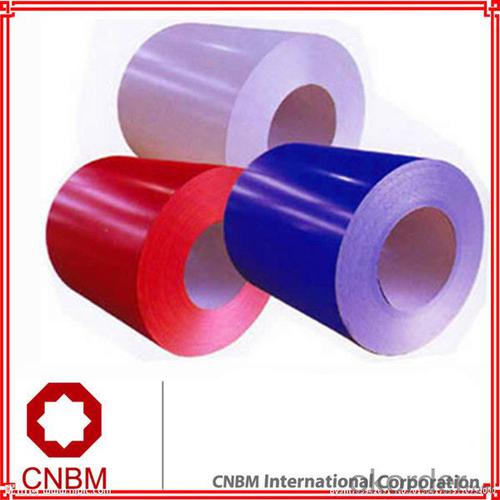

Coated steel coil with galvanized and color from china suppiler

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Coated steel coil with galvanized and color from china suppiler

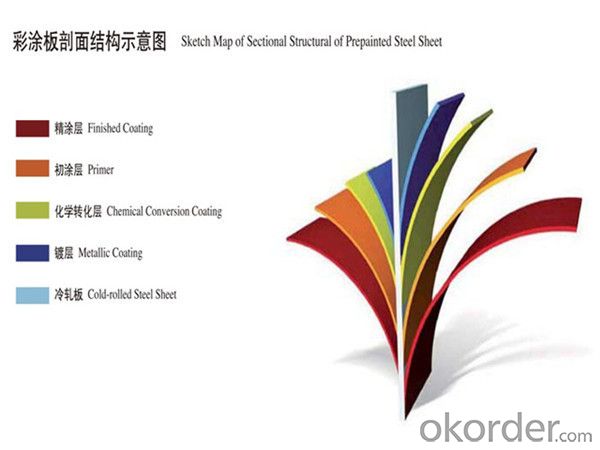

Prepainted steel sheet /coil is coated with organic layer, which provides higher anti-corrosion property and a

longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc

coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon

modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Packing:

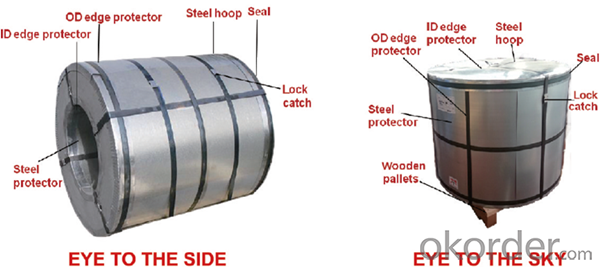

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: Can steel coils be used in the production of agricultural equipment?

- Indeed, agricultural equipment production can make use of steel coils. In the manufacturing process, steel coils frequently serve as a fundamental material for various agricultural equipment like plows, planters, harvesters, and tillers. The robustness and endurance of steel render it suitable for demanding agricultural applications. Furthermore, steel coils can be easily molded and shaped into diverse parts and components that are necessary in agricultural machinery. Steel's resistance to corrosion also guarantees that the equipment can withstand severe weather conditions and extend its lifespan. All in all, incorporating steel coils into the production of agricultural equipment aids in ensuring the dependability, durability, and effectiveness of the machinery employed in farming operations.

- Q: why do you need to heat steel when hardening, molecules etc etc

- Halps is off base a little. The reason heat is involved in hardening of steels depends, a little bit, on how you are doing the hardening. If you are hardening by work hardening, you do not have to heat it at all. If you are barbarizing (case hardening), the temperature is raised to increase the diffusion rate of carbon into the steel, higher C content - higher hardness. If you are Thur hardening, you have to heat the steel to the austenitizing temperature (so the structure transforms to FCC crystals with higher solubility for C) and then quench it (cool it rapidly enough to freeze the C atoms in the martensite crystal structure). If you slow cool, the steel could end up softer than it started. All of these processes involve atomic level things. If you want to understand them on the atomic level, you need to study physical metallurgy of steels. It is a subject onto itself and is really quite fascinating if you are interested.

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- There are more than 10,000 different steel alloys that have been specified and used for different purposes. They cover a huge range of mechanical properties. For silver, are you talking about pure silver, or a silver alloy with a additives to improve its mechanical properties? Typical values for mild steel at room temperature are E = 210 GPa, G = 80 GPa (source: 30 years working as a mech. engineer) Wikipedia gives E = 80GPa, G = 30GPa for pure silver (temperature not specified). Silver alloys may be very different from those values. The properties will also depend on the metal forming process (e.g. drawn wire, annealed, etc). NB some alloys with silver in their common name contain no silver at all.

- Q: What are the dimensions of steel coils used in the metal furniture industry?

- The dimensions of steel coils used in the metal furniture industry can vary depending on the specific requirements of each manufacturer. However, commonly used dimensions include coil widths ranging from 24 to 60 inches (61 to 152 cm) and coil diameters ranging from 36 to 72 inches (91 to 183 cm). The thickness of the steel coils can also vary, typically ranging from 0.020 to 0.250 inches (0.05 to 0.64 cm). These dimensions allow manufacturers to efficiently produce various types of metal furniture, such as chairs, tables, and cabinets, by utilizing the steel coils as raw materials for their production processes.

- Q: How do the sandpaper grits compare with different coarse levels of steel wool? For example, I'm finishing a homemade entertainment center, and using a tinted polyurethane, and it says to use 000 grade steel wool, but mine is #3, could I use some sanpaper instead, and what grit?

- 150 grit is standard for final sanding for poly. You could use 220 if you finish with something thinner like lacquer of if that's all you have. Even finer would work but not do much sanding.

- Q: How are steel coils processed for edge conditioning or slitting?

- Steel coils are processed for edge conditioning or slitting through a series of mechanical operations. The process involves unwinding the steel coil, leveling it to remove any deformities, and then passing it through a slitting machine to cut it into narrower strips. For edge conditioning, the strips are further processed to remove burrs and create smooth, precise edges. Overall, these processes ensure that steel coils are transformed into accurately sized and finished products suitable for various industrial applications.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are processed for cutting to length or blanking through a series of steps. First, the coils are uncoiled and straightened to remove any bends or twists. Then, they are fed through a machine that measures and marks the desired length or shape. Next, a cutting tool or die is used to precisely cut the steel into the required dimensions. Finally, the cut pieces are inspected for quality and packaged for shipment.

- Q: Can steel coils be stored outdoors?

- Yes, steel coils can be stored outdoors. However, it is important to protect them from exposure to moisture and extreme weather conditions, as these can cause corrosion and damage to the coils. Proper covering or shelter should be provided to ensure their longevity and quality.

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through a combination of visual inspection and non-destructive testing methods. Visual inspection involves a thorough examination of the edges of the coils to identify any visible defects such as cracks, chips, or uneven edges. This is typically done by trained inspectors who carefully inspect the entire length of the coil. Non-destructive testing methods are also used to detect any hidden defects or imperfections in the edges of the steel coils. These methods include ultrasonic testing and magnetic particle inspection. Ultrasonic testing involves the use of high-frequency sound waves to identify any internal flaws or discontinuities in the steel. Magnetic particle inspection, on the other hand, uses magnetic fields and particles to identify any surface or near-surface defects in the steel. Both visual inspection and non-destructive testing methods play a crucial role in ensuring the edge quality of steel coils. By conducting these inspections, manufacturers can identify and address any defects or imperfections in the edges of the coils, ensuring that they meet the required quality standards.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws by being unwound and fed into a machine called a screw-making machine. The steel coils are typically made of high-quality steel, which is cut into smaller strips that can be easily shaped into screws. These strips are then fed into the machine, which forms them into the desired screw shape and cuts them to the appropriate length. So, steel coils serve as the raw material that is transformed into steel screws through the manufacturing process.

Send your message to us

Coated steel coil with galvanized and color from china suppiler

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords