Aluminum Corrugated Metal Sheets - Coated Aluminium Coil AA3003-H16, 0.62mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

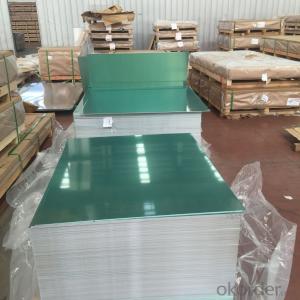

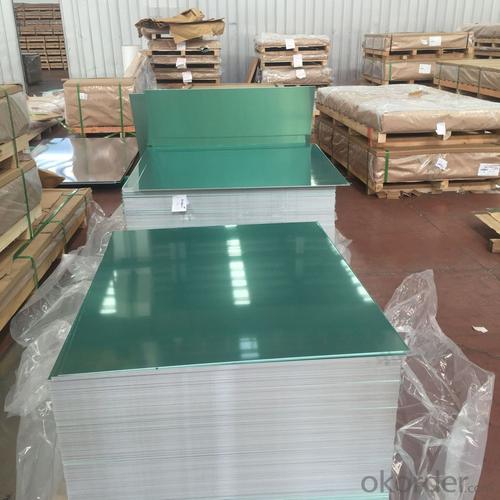

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

4.Aluminum Coils Colored Coated Specification

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- Potassium Aluminum Hydroxide

- Q: Are aluminum sheets suitable for construction purposes?

- Yes, aluminum sheets are suitable for construction purposes. Aluminum is a lightweight material with excellent strength-to-weight ratio, making it an ideal choice for various construction applications. It is corrosion-resistant, durable, and has a high melting point, which allows it to withstand extreme weather conditions and temperature fluctuations. Additionally, aluminum sheets can be easily formed, shaped, and fabricated to meet specific construction requirements. They are commonly used in roofs, wall cladding, window frames, doors, and other structural components in residential, commercial, and industrial buildings. Overall, aluminum sheets offer numerous advantages in construction, making them a suitable choice for a wide range of construction purposes.

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- With aluminum, you would need to purchase a special aluminum darkening chemical if you do not want to risk warping the metal using the heated olive oil technique. The chemicals (brands such as Jax or Birchwood Casey) are available at many hobby shops.

- Q: With a project I'm working on, I need to reinforce a small case made of aluminium. My options are to use regular old screws (probably steel) or Stainless Steel screws (much more costly). Just wondering what corrosion will be like? *It will never ever get wet,* so does that mean corrosion will not occur? (to a certain degree, obviously) And would corrosion, since its dry, still be affected by the type of metal used for the screws? The screws need to be strong, and they also need to be purchase-able at a regular hardware store, as I'm not going to go buying just screws on-line. Thanks for any info you can provide.

- You don't mention just what this project is, but 'regular' screws in the aluminum will not 'rust' - but they may cause galvanic action (a white powdery aluminum oxide may form over time.) Most hardware stores carry aluminum screws, why not just buy and use them if you are concerned? They are usually used for aluminum replacement windows and may be painted white. You can use sandpaper to remove the paint if you want the silver to show.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. Aluminum is a versatile and popular material in the construction industry due to its numerous benefits. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for architectural wall panels, as it reduces the overall weight of the structure, simplifies transportation, and allows for greater flexibility in design. Additionally, aluminum offers exceptional durability and resistance to corrosion. This is crucial for wall panels, as they are exposed to various environmental elements such as rain, UV rays, and temperature changes. Aluminum's natural oxide layer provides a protective barrier, ensuring that the panels remain intact and maintain their appearance over time. Aluminum also provides excellent thermal and acoustic insulation properties. Architectural wall panels made from aluminum can help regulate the internal temperature of buildings, leading to energy savings and improved comfort for occupants. Moreover, aluminum panels help reduce noise transmission, contributing to a quieter indoor environment. Furthermore, aluminum is highly customizable in terms of shape, size, color, and finish. This allows architects and designers to create unique and visually appealing wall panel systems that complement the overall aesthetics of a building. The versatility of aluminum sheets also facilitates the integration of other materials, such as glass or stone, for added design possibilities. Lastly, aluminum is a sustainable material. It is 100% recyclable, and the energy required for recycling aluminum is significantly lower compared to the production of primary aluminum. Choosing aluminum sheets for architectural wall panels aligns with environmentally friendly practices and contributes to the reduction of carbon emissions. Overall, the characteristics of aluminum, including its lightweight nature, durability, resistance to corrosion, thermal and acoustic insulation properties, design flexibility, and sustainability, make it highly suitable for manufacturing architectural wall panels.

- Q: What is the typical flammability rating of aluminum sheets?

- Aluminum sheets typically have a flammability rating of Class A, which means they have a low flammability and are considered non-combustible.

- Q: How do aluminum sheets compare to other metals in terms of strength?

- Aluminum sheets generally have lower strength compared to other metals. While aluminum is lightweight and has excellent corrosion resistance, it is not as strong as metals such as steel or titanium. Aluminum has a lower tensile strength and yield strength compared to these metals, making it more susceptible to deformation and failure under heavy loads. However, aluminum can be alloyed with other elements to improve its strength, and specific aluminum alloys can rival or even surpass the strength of some other metals. Additionally, aluminum's strength-to-weight ratio is one of its main advantages, making it a preferred choice in many industries where weight reduction is crucial, such as aerospace and automotive. Overall, while aluminum may not be the strongest metal in absolute terms, it offers a balance of strength, lightweight properties, and corrosion resistance that makes it a versatile material in various applications.

- Q: What are the common thicknesses of aluminum sheets used in aerospace applications?

- The common thicknesses of aluminum sheets used in aerospace applications range from 0.5 mm to 6 mm, depending on the specific requirements and structural needs of the aircraft or spacecraft.

- Q: What are the potential safety issues associated with the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use, but there are a few considerations. They can be sharp when cut, so proper handling is important to avoid cuts. Aluminum is a good conductor of heat, so care should be taken to avoid burns when handling hot aluminum sheets. Additionally, inhalation of aluminum dust can be harmful, so it's important to work in a well-ventilated area or use a dust mask when cutting or grinding aluminum. In terms of long-term health, there's ongoing debate about the safety of aluminum exposure, but it's generally considered safe when used in accordance with proper safety measures.</p>

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

Send your message to us

Aluminum Corrugated Metal Sheets - Coated Aluminium Coil AA3003-H16, 0.62mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords