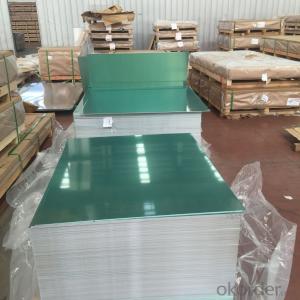

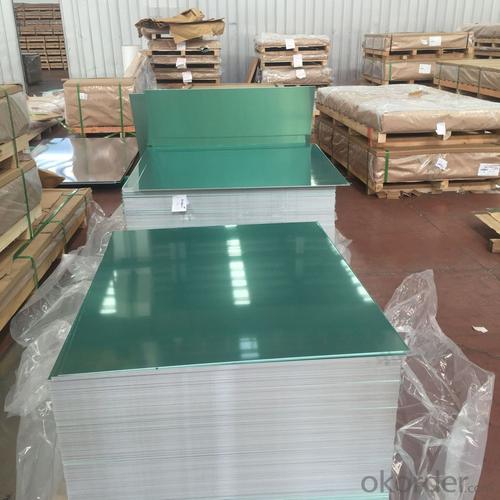

Aluminum Sheets Georgia - Coated Aluminium Coil AA100-H16, 0.72mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

4.Aluminum Coils Colored Coated Specification

Alloy AA1xxx,AA3xxx,AA5xxx

Temper H14,H16,H18,H22,H24,H26,H32,O/F

Thickness 0.03mm-3.0mm

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

- Q: Can aluminum sheet be painted?

- Yes, aluminum sheet can be painted. However, it is important to properly prepare the surface before painting to ensure that the paint adheres well and lasts longer. The process usually involves cleaning the aluminum sheet to remove any dirt, grease, or oxidation, followed by applying a primer to promote better adhesion. Once the primer is dry, you can then apply the paint of your choice. It is recommended to use a high-quality paint suitable for metal surfaces to achieve the best results. Additionally, if the aluminum sheet will be exposed to outdoor elements, it is advisable to use a paint that is specifically formulated for exterior use, in order to provide protection against weathering and corrosion.

- Q: What is the lifespan of aluminum sheets?

- Various factors, such as the aluminum's grade and thickness, the environmental conditions it encounters, and the level of maintenance it receives, can impact the lifespan of aluminum sheets. Aluminum sheets are renowned for their durability and resistance to corrosion, which contributes to their long lifespan. Aluminum possesses natural resistance against rust and corrosion, making it suitable for a wide array of applications. When given proper care and maintenance, aluminum sheets can endure for numerous years. The construction, automotive, and aerospace industries frequently utilize aluminum sheets due to their lightweight nature and robust properties. In outdoor settings, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. Nevertheless, continuous exposure to certain chemicals or corrosive substances can gradually cause damage. To prolong the lifespan of aluminum sheets, it is crucial to regularly clean and safeguard them. This entails eliminating any dirt or debris that might accumulate on the surface and applying protective coatings or treatments as necessary. In conclusion, while it is challenging to provide an exact timeframe for the lifespan of aluminum sheets, they are generally regarded as a long-lasting material that can withstand the test of time when adequately maintained.

- Q: What are the different thicknesses available for aluminum sheet?

- Aluminum sheets are available in a variety of thicknesses, ranging from extremely thin to thick. The thickness of aluminum sheets is measured in gauge or millimeters (mm), with each gauge representing a specific thickness. The most common gauges for aluminum sheets include 22, 24, 26, 28, 30, and 32. These gauges correspond to thicknesses ranging from 0.0254 mm to 0.635 mm. Additionally, aluminum sheets can be found in thicker gauges, such as 16 gauge (1.29 mm) or even thicker for specialized applications. The choice of thickness depends on the intended use of the aluminum sheet, with thinner sheets often being used for lightweight applications like electronics or packaging, while thicker sheets are preferred for structural or industrial purposes.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are highly resistant to saltwater corrosion.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- Simply put, aluminum plate is pure metal, aluminum plate is only the surface of metal (surface metal processing), and the middle is polyethylene plastic.In the same thickness and specifications, the aluminum plate is heavier than the aluminum-plastic plate, and the price is generally higher than that of the aluminum plate. 2.5mm aluminum plate to see, polyester or fluorocarbon, aluminum material, machining drawings, are often n flat at around 250, aluminum plate, aluminum depends on the thickness of the plastic type and so on normal inner wall 40 yuan a square, 100 yuan per square wall aluminum plate and aluminum plate installation is a kind of the aluminum is only good processing and molding to the site, and then to the site after the aluminum plate molding, aluminum plate manufacturer's website will generally some. There are also some details please consult the steel E station through

- Q: How does 1200X1200X15 6061 aluminum, CNC processing, the plane degree can reach the number of my clients to 0.2, but I used to use the MS 1000X1500X70 to the material processing, the flatness is only 1, please experienced friend to help, thank you

- The first rough machining, no precision position of the first place, finishing allowance for heat treatment of unilateral 0.15MM, and then remove the stress of 420 degrees Celsius for 4 hours, with the furnace cooling (very important), doing fine processing, can guarantee within 0.03

- Q: Are aluminum sheets suitable for bulletproof applications?

- No, aluminum sheets are not suitable for bulletproof applications.

- Q: What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q: What is the typical thermal conductivity of aluminum sheets?

- The typical thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin (W/mK). This high thermal conductivity makes aluminum an excellent heat conductor, which is why it is commonly used in applications where heat transfer is important, such as in heat sinks, power transmission lines, and cooking utensils.

Send your message to us

Aluminum Sheets Georgia - Coated Aluminium Coil AA100-H16, 0.72mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords