CMAX Lateste Derrick Crane TCD3016 with stable quality and good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 6666 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

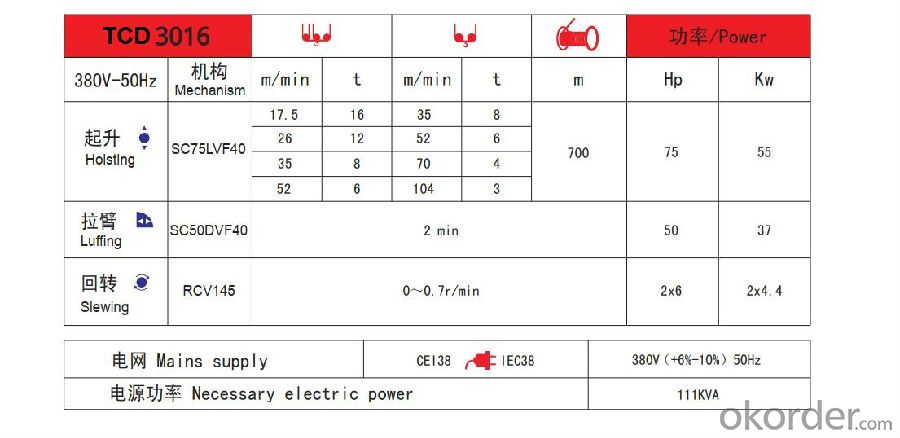

Mechanisms

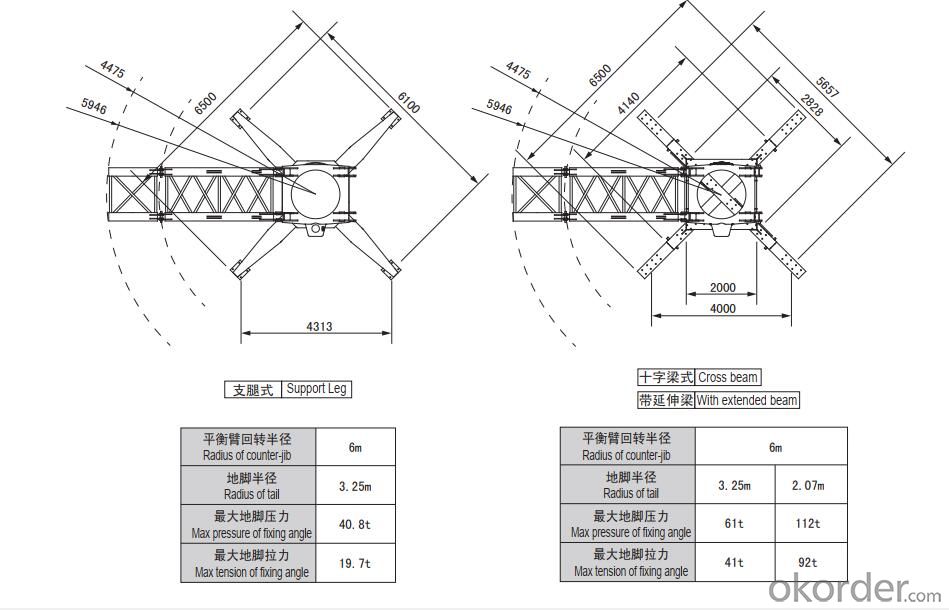

Radius of slewing and load

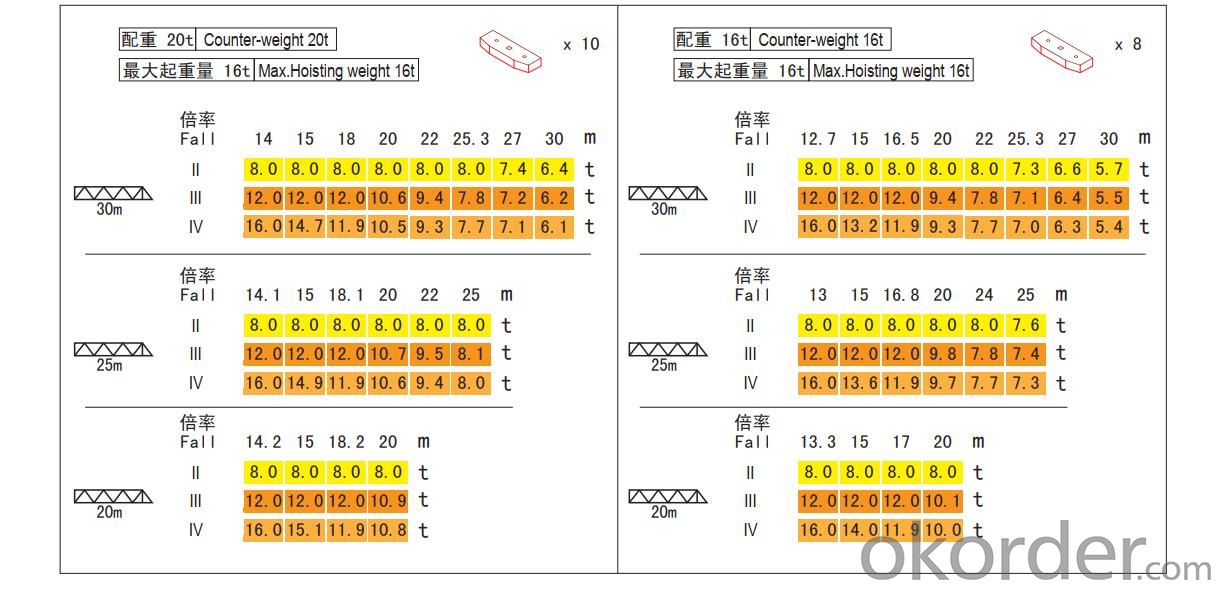

Load Diagram

Our main advantages:

1.CNBM honored Fortune Global 500 since 2011.

2, CNBM is the biggest state-owned company which has had been awarded Qualified construction equipment manufactures and most of the big project are using our products;

3, CNBM possess key technical research department and could design & produce special machinery for international clients.

4, We have had passed ISO9001:2008,CE and etc.

5. The successful long-time construction machinery operation in the world testifies that out machinery performance is stable.

6. More than 10 overseas branch office provide immediate commercial convenience and after service.

THAT’S WHY WE CHOOSE CMAX TOWER CRANE

1. Advanced technology

The most advanced technology is adapted to our product design. All concerned matters such as raw material selecting, structure designing, working mechanisms, control system, efficiency, safety and reliability can reach the world level. And structure parts designed by three-dimensional software and force calculation software, make sure high Safety and perfect performance.

2. Craftsmanship

(1) New Advanced equipments for rust-removing applied in material pretreatment process to ensure rustless structure welding.

Panel mast section after Sand blasting

Integrated mast section after sand blasting

(2) Precise data control cutting machine ensures accurate specification of each component.

(3) CO2 shielded arc welding ensures welding quality thereby enhances the longevity of the products.

(4) High-quality surface coating that can meet different requirements of transporting and using. It is durable under environments of low, high, wet as well as oceanic environment.

(5) The pin-connected mast sections ensure a very short assembling time, visual check and easy assembling. Our mast’s cross-sections including: 1.6 x 1.6 m, 2 x 2 m and 2.45 x 2.45 m, easier for transport with dismountable panels design.

3. Leading technology of working mechanism

(1) Hoisting mechanism: Equipped with frequency inverter & multipolar dynamo (For lifting capacity≥10T). With Optima, the hoisting speed is optimized depending on the load. For each load level, the inverter authorizes the highest possible speed (hoisting or lowering), thus improving the productivity. It’s more convenient for maintenance work by the Human / Machine dialogue carried out by screen and keyboard.

(2) Trolleying mechanism: Equipped with frequency inverter(For lifting capacity≥10T) and wound-rotor motor can also applied to conduct speed regularly. Make trolley moving more economic and efficient. Diagnosis aid by screen and keyboard

(3) Slewing mechanism: Equipped with frequency inverter (For lifting capacity≥10T) or HRCV controller, make sure slewing with high productivity (stable speed, correct stopping angle), can control over several motors in the meantime.

4. Control system

Using of electronic components from world famous brands such as SCHNEIDER, YASKAWA, SIEMENS and MITSUBISHI, that ensures stability and reliability of the products. And all of the cables which applied in our product select domestic well-known brands.

5、CMAX tower crane is equipped with inspection system (like black box,optional), which could store 10000 tower crane operation reports, easy to inspect and diagnose.

6. CMAX tower crane will past all the inspection before leaving our factory, we always adheres the principle “Quality is the priority, management is the essential”. Every unit tower crane will be inspected by our quality control department, and the main welding line of tower crane will be inspected by ultrasonic flaw detection to ensure high quality.

7. CMAX have several excellent and professional encasement team, ensure our product avoid any damage in the shipping process.

8. CAMX can supply more than 40 professional & experienced overseas engineers for installation and after sales field.

9. CMAX has strong scientific research strength, we can supply customized non-standard tower crane which based on customer special requirement, also supply spare parts for world-renowned brand tower crane, such as POTAIN, LIEBHERR, TEREX, etc.

10. With the competitive prices, high quality, and best services, CMAX tower crane have covered from 4t capacity to 100t capacity in the international markets, which also include fixed type, undercarriage type and undercarriage & travelling type.

- Q: Preferable short poems or phrases in Chinese.

- this one is about cranes We thought they were gulls at first, while they were distant- The two cranes flying out of a natural morning, They circled twice about our house and sank, Their long legs drooping, down over the wood. We saw their wings flash white, Frayed at the black tip, And heard their harsh cry, like a rusty screw.

- Q: All types of jack up cranes. How is the maximum lifting torque converted?

- Tower crane lifting torque = crane maximum lifting weight * maximum operating range; for example: the maximum lifting weight is 2T*, the maximum operating range of 50 meters =1000KN.m.

- Q: How about the installation and disassembly of the tower cranes?

- Authorized by the national security inspection department, the local special operations training school or the technical quality supervision bureau, after the study, assessment, qualification and graduation permit, will give you special operations installation, removal operation certificate.

- Q: Please help!

- this would help you i hope good luck researching

- Q: More than meters of tower cranes must be equipped with red barrier lights at the top

- To see the land of tower crane or floating crane... Basically,

- Q: I know that the whooping crane population recovered through captive breeding but how many are left currently (right now).

- There were 535 total in 2009--the population increased slightly last year but I have not seen a total for the population of 2010. Deaths can occur at any time so the number changes constantly. The Journey North site counts 281 adults in the wild western population and 106 birds in the reintroduced eastern flock. They did not give a number for the birds in captivity so I cannot give you a total. You can follow the reintroduced whooping crane population and their migration each spring and fall on the Journey North (in fall called Journey South site). They also track song birds and hummingbirds and monach butterflies.

- Q: im 35 and in august i get my license back and i am going after my childhood dream of being a crane operator and was wondering how i need to go about achieving this?

- I am sorry I do not know where are you from as different country might have different requirement on getting a Crane Operator licence. Anyway, I believe the basic is the same: You need to attend a theory class on crane operations which usually include topics like design theory of cranes, slinging and lifting, signalling. After this, there will be a practical session to test your understanding and practical operations on an actual crane in the training center's facility. Good Luck and May You Attain You Dream :)

- Q: i was wondering

- it would be better if you tried it. :P Ive never heard the story but this is actually wishing magick. so I would vote true on it, but i think there are better wishing methods that won't require that much time and won't kill trees. Blessings, Shadow

- Q: cover up? I know he was into pornography and who knows what else!

- Crane had just spurned his long-time friend John Carpenter. Carpenter was tried for the murder based on blood found in a car he rented, however he was acquitted as a murder weapon could not be found. The case remains officially unsolved.

- Q: the part of the crane which balances the lifting arm.

- What okorder /... Always wanted to see one erect itself, they just seem to spring up overnight. Wingman

Send your message to us

CMAX Lateste Derrick Crane TCD3016 with stable quality and good price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 6666 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords