Clear Pattern Glass RH-3 3.5-5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25T m.t.

- Supply Capability:

- 500 Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

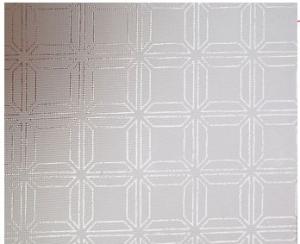

Model Number: Clear RH-3 Pattern Glass

Function: Acid Etched Glass,Heat Absorbing Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Figured Glass,Frosted Glass

Type: Pattern Glass

Product Name: Pattern Glass

Size: 1500*2000mm, 1830*2440mm

Thickness: 3.5mm, 4mm, 5mm

MOQ: 25Tons

Payment Terms: T/T or L/C

Packing: Wooden crates worthy for ocean and land carriage.

Delivery Detail: Within 15 to 25 days after deposit payment or L/C

Features of Pattern Glass

Its wide range of patterns makes it highly suitable for decorative applications. Its surface patterns allow diffused daylight transmission but prevent visibility of activity, thus ensuring privacy.

- Q: Which glass factory has good glass?

- If the original piece of glass with good quality of Qingdao Jin Jing, Jiangmen farun, TGI, CSG, luoyang.... These glass plants are relatively stable, and is a large enterprise, if the processing technology is good, it depends on the processing unit of the process, this is not recommended.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- The main raw material for making glass!! Simply means that the silicon containing sand, ordinary sand containing silicon. Generally, the sand with more silicon content is the good material for making glass. The technology of glass has been developed for more than 5000 years. It was not until twentieth Century that glass became an industrial material and developed rapidly.

- Q: What materials do we need to make glass septic tanks?

- Advantages of glass reinforced septic tanks:Good impermeability:1., high polymer material as the base material, good sealing, never leak.2. construction speed.3. products for factory production of finished products, site construction is fast, and the high water level, rainy season can also be construction.4. clear long cycle.5., the anaerobic fermentation is sufficient, the silt deposition quantity reduces greatly, the clear cutting cycle prolongs 3-4 times, greatly reduces the follow-up operation and the maintenance cost.6., treatment effect is good.7., set aside bins, hierarchical fermentation, sewage discharged in the BOD, COD and other pollutants significantly reduced.8., small footprint.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- Finished product protection: because the construction environment belongs to the pool irrigation, it is not conducive to the curing of epoxy forming, so it must take 48 hours curing time, to be fully cured after use.

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: The difference between glass wool, rock wool, mineral wool

- Originated in Hawaii. Rock wool products are high-quality basalt, dolomite as the main raw material, the high temperature above 1450 DEG after melting by four axis high speed centrifugal centrifuge international advanced fiber, and spray with a certain amount of binder, dustproof oil, water repellent cotton collector after collection, through the pendulum method, and three-dimensional method after cotton spreading curing, cutting, rock wool products form different specifications and applications.

- Q: Tempered and reinforced glass

- National construction technical specification for application of glass JGJ113-2003 provisions of the landing door glass must use safe glass, is from the protection of person to consider.

- Q: How is glass made, raw material proportioning?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

- Q: What material is used in the protective film in the middle of glass?

- Production process is:1: opening, the entire glass will be cut into a larger size than the molding of 0.6mm pieces.2:CNC carved, will open material scrap with steel sand grinding chamfering, drilling (or slot), after the end of CNC on the forming of the carved glass3, flat grinding, mainly to deal with the opening and CNC caused by surface scratches.4: cleaning, ultrasonic cleaning machine will be washed flour, while drying glass.5: tempering, the use of potassium acid to strengthen the glass, so that the stress of glass, strength, resistance and so on to meet certain requirements.6: cleaning: the tempered glass re-entry ultrasonic cleaning.7: stick ab8: packing finished products

- Q: Is flat glass the main material or structural component in raw materials?

- But sometimes the structural parts, such as the exhibition hall and the hall, have a transparent floor beneath which the contents are displayed. In order to save the raw materials, they may be designed to be cut from the whole glass without cutting into the box. At this time the flat glass is load-bearing components, to calculate its carrying capacity, which is the structural components of the.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America5 South America 22 Eastern Europe 4 Southeast Asia 7 Africa 25 Oceania 6 Mid East 25 South Asia 6 |

| Company Certifications | AS/NZS2208:1996 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao,Tianjin,Dalian |

| Export Percentage | |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, French, Russian |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Clear Pattern Glass RH-3 3.5-5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25T m.t.

- Supply Capability:

- 500 Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords