CINCP / CINCN,Vertical "CANTILEVER" pump with base plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design |

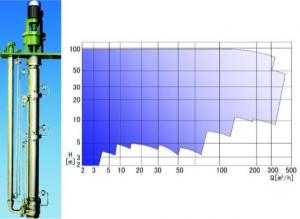

Overview of technical data

| Type of impeller | Open |

| Maximum drive rating | 184 kW |

| Impeller material (EN standard) | CA6NM; CF8M;JL 1040 |

| Type of bearing | Rolling element bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 3. 500 1/min |

| Maximum flow rate | 320 m³/h |

| Maximum discharge-side pressure | 10 bar |

| Top plate | Yes |

| Casing material (EN standard) | CA6NM; CF8M;JL1040 |

| Minimum flow rate | 0, 70 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| Pump set location | Dry installed, floodable |

| Max. permissible fluid temperature | 100 °C |

| Type of first impeller | Single entry |

| Main applications | Industry and process engineering; Water |

| Type of installation | Stationary |

| Type of casing | Volute casing |

| Type of lubrication | Grease / Oil lubrication |

| Type of drive | Electric motor |

| Installation position | Vertical |

| Shaft material (EN standard) | AISI- 316L;F-114 |

| Type of coupling | Direct |

| Shaft seal type | Shaft seal ring |

| Drive | Electric motor |

| Maximum head | 95, 00 m |

| Minimum head | 3, 50 m |

| Explosion protection | ATEX ( 94/9/EC) |

| Casing partition | Radially split |

| Maximum submergence | 1. 585 mm |

| Connection to power supply | 230/ 400 V, 3~ |

- Q: that question is related to basic fluid machinery... the reaction turbines, when running are full of water that is the water is all around the vanes but in the analysis we use to draw a single line representing the inlet velocity why?????

- resultant force acts on the line

- Q: Hi,I would like to have machinery and machine in sentence so that I can understand the meaning

- A sewing machine is a mechanical device used for sewing cloth. A sewing machine is a piece of machinery.

- Q: I swore into the Navy and i chose MR over a few other jobs, the other jobs sucked and they said this was the better one of them all. Do you know where MR's are usually stationed and if its a cool job? thanks

- It's ok. As an MR, your job is to become proficient in the operation of heavy machinery and damage control equipment. Specifically, you will become skilled in working a lathe and die set to manufacture small parts and things for the ship (and you will be stationed on ship-MR is a sea-intensive rate). You also will make a lot of name tags and Bakelite placards, since you own the engraving machine. With the caveat that my experience is all small boy (FF/DDGs), here are the pros/cons of the job. Pros-learn really technical skills that can come in handy throughout life. Work with your hands. People want to be friends with you so you can hook them up with placards. Usually one of only a few on a ship-you as one man (or woman) can make a lot of difference. Cons-Work as part of Repair Department/Division, normally a pretty screwy, unorganized mess of a unit. Lots of knowledge-have to learn the DC/HT job as well. Especially on small boys, have to contribute to Engineering Department manning/watch, lots of work there. It's not a bad rate, but it is a lot of work, like everything else in the Navy.

- Q: i.e lawn mower, snow blower

- Almost every city now has metal recyclers that come to you and pick up your metal. Look in your phone book under recycling, or your local paper for ads.

- Q: What boat propulsion machinery is steam driven?

- Are you asking about the old fashioned paddle wheels, which were steam driven (hence the name steam boat), and later propellers were steam driven. Now electric generators can be steam driven, as in nuclear powered vessels. John seems to have summarized that pretty well.

- Q: Could people in the 1800s have been able to produce/process aluminum with steam powered machinery?

- Yes, of course. Why not? It's just another source of mechanical power. Production of aluminum from ore is VERY power-intensive. We do it by melting the ore and then running electricity through it. So it depends on (1) getting a mass of crushed rock so hot it melts (which includes building a vessel that can stand that heat! (2) Producing electricity of sufficient wattage. This kind of technology was not as possible in the age of steam. Did you know Napoleon and Josephine ate with silverware made of aluminum? At the time it was more valuable than gold!

- Q: Bechtel Machinery stock currently sells for $65 per share. The market requires a 14 percent return on the firm's stock. The company maintains a constant 8 percent growth rate in dividends. What was the most recent annual dividend per share paid on this stock?

- Bechtel Stock Price

- Q: why are safety symbols placed near electrical machinery ?

- Because it can be dangerous.

- Q: When a crematorium, for instance, which is not an industrial building but requires heavy machinery, is constructed, are the environmental systems, like HVAC and mercury abatement systems, or the actual furnaces themselves brought to site in pieces and assembled at first fix stage or put in place before the roof or slab above goes on? Or are they just serviceable by a separate large entrance?

- Large entrance is best. Long ago setting equipment then constructing the walls was a common practice. When the original machines need to be replaced it is a problem.

- Q: Which one is easier and why ? Which one is better pay ?

- All the rattling hippies surrounding it seeking to give up me from taking down the ones timber on account that squirrels reside there. I was once approximately to run the over, the hippies no longer the squirrels, however the boss stated no.

Send your message to us

CINCP / CINCN,Vertical "CANTILEVER" pump with base plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords