China Factory Wholesale Customized 3Mm 4Mm 8Mm 12Mm Fireproof Heatproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

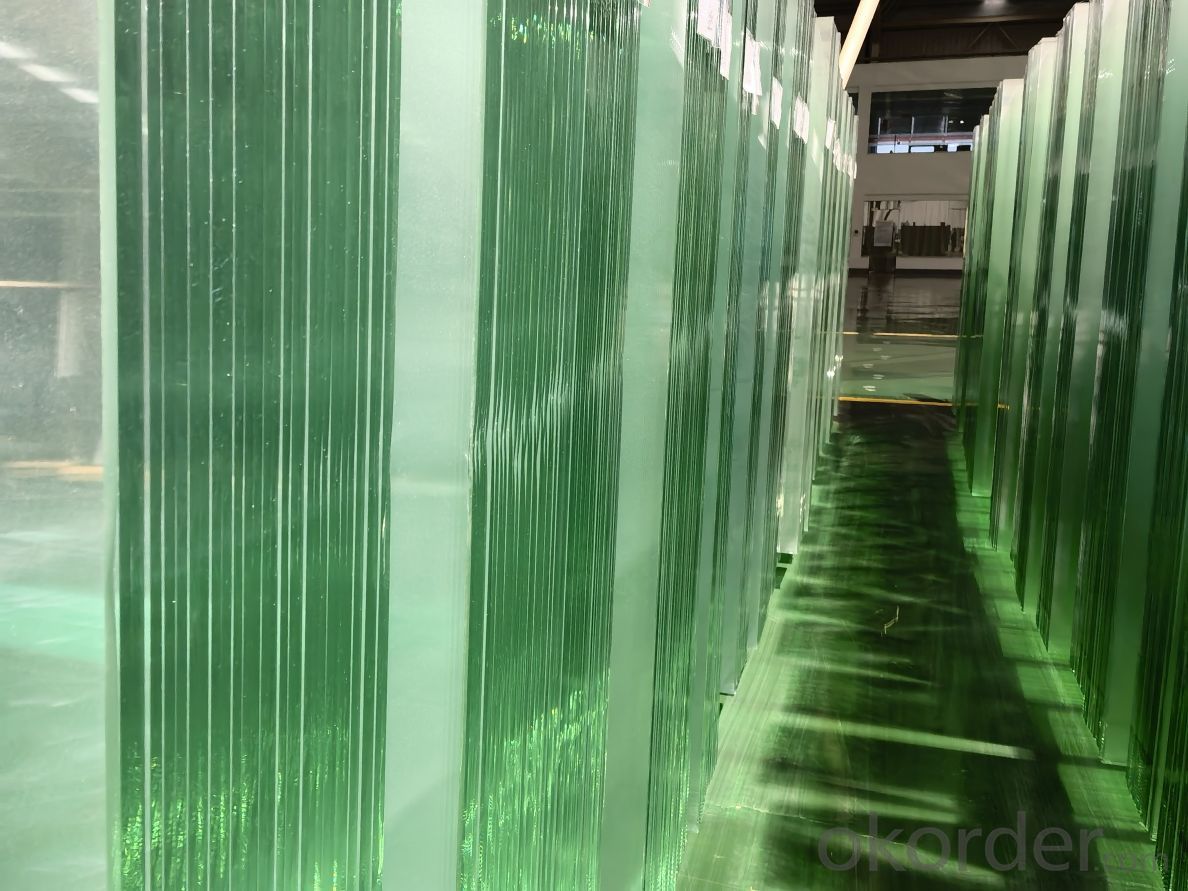

China Factory Wholesale Customized 3Mm 4Mm 8Mm 12Mm Fireproof Heatproof

Fireproof Glass Advantages:

Borosilicate 4.0 fireproof glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 4.0 fireproof glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

Features:

1. With continuous temperatures to 700 degree

2. Thermal shock resistant

3. High stability and durability.

4. Available in bent, curved and flat configurations

5. Best security against the dangers of the fire due to an unbeatable temperature resistance

Excellent view of the dancing flames and a cozy feeling of warmth guaranteed by a high transparency.

Specification:

Type | fireproof glass |

Thickness can choose | 3-4.5mm |

Glass edging | Flat polish, pencil polish, miter, bevel, O.G. bull nose and etc |

Features | Fireplace glass |

Certificate for factory | ISO 9001 2008, ISO 14001 2004 |

Color | Clear, Ultra Clear, Various Green, Blue, Gray, Brown |

Shape | bent, curved and flat |

Package | Pckage with foam board, cardboard boxes, wooden crates,also can pcak according to cusomer's requirement |

Application | Door for fireplace and stove |

OUR PACKING

Wooden crate, carton box, plastic film, customized, all packing can be fulfilled at Glass.

professional and experienced working stuff, all packing and loading is guaranteed to be strong and seaworthy to reduce the breakage rate to as low as possible.

Package Type:

1)Inter package is paper or plastic between two sheets;

2)Seaworthy wooden crates;

3) Iron belt for consolidation for insulated glass

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Decoration decoration materials, fire performance in line with the technical standards of fire how to apply for documents?

- Supplier of the test report (a qualified inspection agency issued, preferably the National Fire Building Materials Quality Inspection and Supervision Center report), some places require on-site sampling, then, according to their flower lambs can be cut off the snow Grinding rules do it.

- Q: Will the fire paint in general can buy it? Guiqiu.

- Looking for me on the line, good quality, but also cheap

- Q: Do you need to do floor fire isolation? There are those regulations for fire protection

- 2.10 The cable wells and pipe wells in the building shall be burned at every floor of the building. The non - combustible body shall not be used at a level not exceeding the fire resistance of the floor. Or fire blocking material plugging.

- Q: Polyurethane fireproof material really effective?

- The effect is not burning, but smoke will not fire

- Q: What is the fire insulation material

- Fireproof fireproof fireproof fireproof fireproof fireproof fireproof fireproof fireproof fireproof

- Q: Short point is to do hand copy

- The three conditions that trigger the fire are: combustible, oxidant and ignition energy coexist and interact. Explosive conditions are: explosives (containing reducing agents and oxidants) or combustibles (combustible gas, steam or dust) and air mixture and the initiation of energy at the same time, interaction. If we take measures to avoid or eliminate one of the above conditions, you can prevent the occurrence of fire or explosion, which is the basic principle of fire and explosion.

- Q: B1 refractory material refractory time long?

- France to make trouble to wear moxibustion smoked but wiping this depends on the specific parts, there are norms of the table.

- Q: What are the grade I fireproof materials? Which can replace joinery and gypsum board?

- Fireproof materials I know there are rock wool, glass magnesium, our company's production of rock wool purification board, glass magnesium purification board are A-level, there are some materials is also. Hai Zhen purification materials Co., Ltd., you can go to Google search on the corporate website to look at, here can not send the site!

- Q: Polystyrene board is A-class or B-class fire insulation materials

- Should be C level, if the composite inorganic sheet should be B-class material

- Q: Class C fire door with what material

- Class C fire door with what material...

Send your message to us

China Factory Wholesale Customized 3Mm 4Mm 8Mm 12Mm Fireproof Heatproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 10000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches