Hooks for Ceiling Grid - Ceiling Tee Grid for Suspension System Use Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)24T Tee model:

a)Main tee: 24x32x3.0m,or3.05m,3.60m,3.66m

b)Cross tee: 24x26x1.2m,or1.22m

c)Cross tee: 24x26x0.6m,or0.61m

d)Wall angle: 22x22x3.05m,or3.60m

e)Thickness: from0.23mm,0.25mm,0.28mm,to0.30mmand0.40mm

2) 24T Tee model:

a)Main tee: 24x38x3.0m,or3.05m,3.60m,3.66m

b)Cross tee:24x28x1.2m,or1.22m

c)Cross tee:24x28x0.6m,or0.61m

d)Wall angle:22x22x3.05m,or3.60m

e)Thickness:from0.23mm,0.25mm,0.28mm,to0.30mmand0.40mm

3) 15 T Tee model:

a)Main tee: 15x32x3.0m,or3.05m,3.60m,3.66m

b)Cross tee: 15x26x1.2m,or1.22m

c)Cross tee: 15x26x0.6m,or0.61m

d)Wall angle: 22x15x3.05m,or3.60m

e)Thickness: from0.23mm,0.25mm,0.28mm,to0.30mmand0.40mm

4) 15T Tee model:

a)Main tee: 15x38x3.0m,or3.05m,3.60m,3.66m

b)Cross tee:15x28x1.2m,or1.22m

c)Cross tee:15x28x0.6m,or0.61m

d)Wall angle:22x15x3.05m,or3.60m

e)Thickness:from0.23mm,0.25mm,0.28mm,to0.30mmand0.40mm

Ceiling suspension grids are manufactured from hot-dipped galvanized steel. Available in customized specifications.

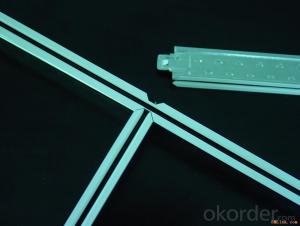

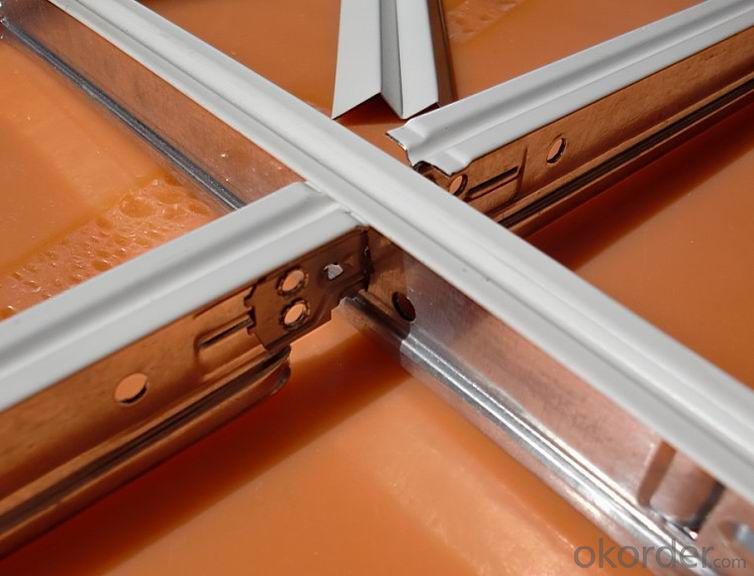

Our ceiling suspension grids are double web cold-rolled sections, manufactured from hot-dipped galvanized steel, The tees section is with pre-painted capped. It is given to ensure that the system is manufactured to a very high quality level.

Suspension Grid--FUT

LOADING QUANTITY:

FUT 32 A1

Main Tee: 30PCS/CTN, total 5400PCS / 180CTNS / 1*20FCL

Long Cross Tee: 60PCS/CTN, total 32400PCS / 540CTNS / 1*20FCL

Short Cross Tee: 90PCS/CTN, total 32400PCS / 360CTNS / 1*20FCL

Wall Angle: 50PCS/CTN, total 4800PCS / 96CTNS / 1*20FCL

Total: 75000PCS / 24000M2

- Q: Light steel keel with what cut

- Cutting machine, scissors can also be used

- Q: There is a ceiling of light steel keel partition to be how high, whether only need to do ceiling elevation, or to be higher than 20cm, or do the top plate bottom ~

- According to the normal process, it should be done first to do the ceiling wall.

- Q: I now decorate a facade, want to save some money, the original use of light steel gypsum board separated from the good, but not what I want the effect, I would like to use the original material change, and listen to people say that gypsum board movement fragile. Demolished on the bad equipment. The specific situation is that there are two rooms are separated by gypsum board, that is, there are four walls are gypsum board, I would like to change the main are: 1, all the gypsum wall to move the location. 2, which has two walls need to take off a large part of the excess. Would you like to ask my friend to see if my program is feasible? I left this point, all reward

- This is not a good answer. Generally there is no way. Because the workers are not so careful. It is broken to break up. There are some just installed on the brush did not brush this can be used. Said that the main look at the workers.

- Q: Home decoration ceiling light steel keel best use what specifications

- Gypsum board to do their own home with 38 main bone .50 main bone can be hanging 50 pay bone with 38 main 0.8 1.0 1.2 / 50 main 0.8 1.0 1.2 thick / 50 paid 0.45 0.5 these can be used to use the best On the use of the national standard with the thickest of the general can be used with their own but with 38 main hanging gypsum board at least 1.0 thick with non-standard is not necessarily good with the national standard is not only in the thickness of the edge of the high only this is to see What are your own materials?

- Q: Is it good to use a light steel keel?

- Most of the ceiling construction is the use of wooden side, most of the light steel keel is used in the tooling.

- Q: For one of my classes I have to do a floor plan with furnishings and electrical and then I also have to do a reflected ceiling plan of the same floor that includes lighting, HVAC, and finished materials. I was just wondering what the difference is?

- The floor plan is taken at an approximate elevation of 5' AFF (above finished floor). This will show walls, fixtures, etc. The reflected ceiling plan is just what it sounds like, the ceiling. This will show the layout for the grid, lights, HVAC supplies and returns, sprinkler heads, etc. They supply different information to different contractors.

- Q: What is the keel of the ceiling?

- Look at your home improvement or tooling, home improvement on the ordinary light steel keel on the line, tooling, then it is recommended to use paint keel with mineral wool board to use, so that sound-absorbing, fire, light will be much better, the domestic star excellent times mine mine Board is very good, you can understand what.

- Q: There is heating the ground, the above to add light steel keel wall how to deal with?

- Plug the door with light steel keel or wood keel seal gypsum board can be, gypsum board interface with a bandage and then paint; light steel keel is easy to cut, open the door is not a problem, load-bearing door frame can be made with steel skeleton, The steel frame and the ground can be welded with angle steel, the angle of the corner with the expansion bolts fixed, steel, in particular, the steel frame and the light steel keel main dragon with wire connection fixed to increase the load-bearing capacity and integrity, Welded attention to rust, and then sealed plate cover, do the door can be trim.

- Q: What is the distance between the main keel? How much is the distance between the keel? What is the spacing of the hanging bars?

- Light steel keel ceiling spacing specification: The distance between the main keel and the main keel can not exceed 1.2m, if more than this distance, and should try to do reinforcement treatment; vice keel and vice keel spacing between 30cm, gypsum board thickness of 9.5mm. If the thickness of the gypsum board is 12mm, the distance between the vice keel can be enlarged to 40cm. But in the actual construction, the vice keel spacing is 30cm, basically no one made 40cm.

- Q: Do not know who can tell me ah

- Fixed hanging rod Fix the hanging rod with expansion bolts. Not on the ceiling, boom length less than 1000mm, you can use φ6 hanging Rod, if more than 1000mm, should be used φ8 boom, should also set the reverse support. The boom can be cold drawn And disk round bar, but the use of disk round steel should be used to straighten the machine. Master's ceiling, boom length less than 1000mm, You can use φ8 of the boom, if more than 1000mm, should be used in the user φ10 boom, should also set the reverse support. One end of the boom is welded with L30 × 30 × 3 angle code (the aperture of the corner code should be determined according to the diameter of the boom and expansion bolt) The other end can be tapped out with more than lOOmm screw, you can also buy finished screw welding. Make a good boom should do Rust treatment, boom with expansion bolts fixed to the floor, with the impact hammer drilling, aperture should be slightly larger than the expansion of the bolt diameter.

Send your message to us

Hooks for Ceiling Grid - Ceiling Tee Grid for Suspension System Use Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords