Carbon Steel S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

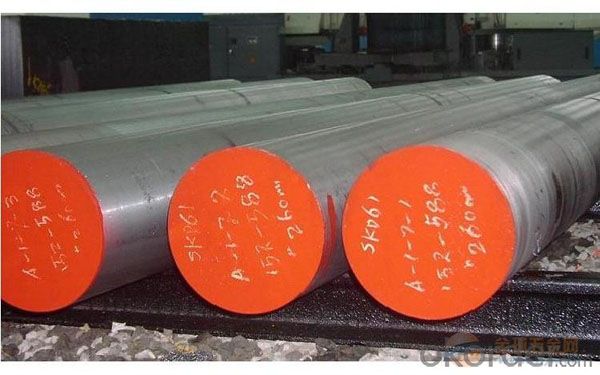

Carbon Steel S20C-B/S45C-B Steel Round Bar

Product Information:

S20C-B/S45C-B steel round bar

Dia 18-60mm

Grade 20,45#

Standard GB,JIS,ASTM,DIN,AISI,BS

LF & VD forge;ISO&TUV approved

S20C-B/S45C-B steel round bar

Round bar steel diameter 18-60mm,material 20#,45#,55#,40CrUP,40CrUC,40Mn2,20CrMnTi,42CrMo

Rolling tube blank diameter 50-130mm.material 20#,45#,10#,35#,37Mn5,Q345,20Mn2/30Mn2,45Mn2,27SiMn

Casting round tube blank diameter160-230mm,material 20#,45#,25Mn,Q345B,20Mn2/30Mn2,45Mn2,27SiMn,33Mn2V/36Mn2V,

Bearing steel diameter18-60mm,material GCr15,Flat spring steel material 60Si2Mn,55CrMnA,50CrVA

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: What are the main applications of special steel in the defense aircraft?

- Special steels are used in defense aircraft for various critical applications such as manufacturing aircraft components, structures, and armor. These steels possess exceptional strength, durability, and resistance to corrosion and heat, making them suitable for challenging environments. Special steels find applications in components like landing gears, engine parts, rotor blades, and missile systems, where their high performance and reliability are essential for ensuring the safety and effectiveness of defense aircraft.

- Q: How does special steel perform in abrasive wear conditions?

- Special steel is designed specifically to excel in conditions of abrasive wear, thanks to its unique composition and manufacturing process. This makes it highly resistant to the harmful effects of abrasion. The inclusion of alloying elements like chromium, manganese, and molybdenum in special steel significantly boosts its hardness and toughness. These elements aid in the formation of carbides within the steel matrix, which serve as barriers against abrasion. The carbides effectively withstand the forces exerted by abrasive particles, preventing them from inflicting significant damage on the steel surface. Additionally, special steel undergoes specialized heat treatment processes like quenching and tempering, further enhancing its resistance to abrasive wear. These processes not only increase the steel's hardness but also enhance its overall toughness and durability. As a result, special steel can withstand high levels of abrasion without experiencing substantial wear or deterioration. Moreover, special steel exhibits excellent corrosion resistance, in addition to its exceptional mechanical properties. This is achieved by incorporating elements such as chromium, which creates a protective oxide layer on the steel surface. The oxide layer acts as a barrier, preventing corrosive substances from reaching the underlying steel and causing further harm. In conclusion, special steel performs exceptionally well in conditions of abrasive wear. Its distinctive composition, heat treatment processes, and corrosion resistance properties make it an ideal material for applications where abrasion is a major concern. Whether in mining, manufacturing, or other industries prone to abrasive wear, special steel offers superior performance and extended lifespan, ensuring optimal efficiency and cost-effectiveness.

- Q: Can special steel be used in mining applications?

- Yes, special steel can be used in mining applications. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as increased strength, durability, and resistance to wear and corrosion. These properties make it highly suitable for various mining applications where the equipment and machinery are subjected to extreme conditions, including heavy loads, abrasive materials, and exposure to water or chemicals. In mining, special steel is commonly used for manufacturing drill bits, cutting tools, crushing and grinding equipment, conveyor belts, and structural components of mining machinery. For example, drill bits made from special steel alloys have improved hardness and toughness, allowing them to effectively penetrate hard rock formations. Similarly, crushing and grinding equipment that utilizes special steel components can withstand the high stress and impact forces encountered during the extraction and processing of minerals. Moreover, special steel alloys provide better resistance to corrosion and wear, which are common challenges in mining environments. This helps to extend the lifespan of mining equipment, reduce maintenance costs, and enhance operational efficiency. Additionally, special steel can be tailored to meet specific requirements, allowing manufacturers to optimize the performance of mining equipment for different mining applications and conditions. Overall, the use of special steel in mining applications offers numerous benefits in terms of improved performance, durability, and cost-effectiveness. Its unique properties make it an essential material in mining operations, enabling the extraction and processing of minerals in a more efficient and sustainable manner.

- Q: How does special steel contribute to reducing weight in applications?

- There are several ways in which special steel can help to reduce weight in applications. Firstly, special steel alloys can be designed to have high strength-to-weight ratios. This means that they can provide the same level of strength and performance as other materials, such as traditional steel or aluminum, but with less weight. By substituting special steel for heavier materials, manufacturers can decrease the overall weight of the application without compromising its structural integrity. Furthermore, special steel can be manufactured with enhanced fatigue resistance and durability properties. This allows for the use of thinner and lighter sections without sacrificing strength. This is particularly crucial in industries where weight reduction is crucial, such as automotive and aerospace, as it enables the production of lighter vehicles or aircraft. As a result, fuel efficiency is improved and emissions are reduced. Moreover, special steel can also contribute to weight reduction through its versatility in manufacturing processes. It can be easily formed, shaped, and welded, allowing for the creation of complex and lightweight structures. This flexibility in fabrication methods empowers engineers to optimize the design and maximize weight savings by utilizing special steel in innovative ways. In conclusion, special steel aids in reducing weight in applications by offering high strength-to-weight ratios, improved fatigue resistance, and durability. Additionally, it provides versatility in manufacturing processes. These attributes make special steel an ideal choice for industries seeking weight reduction, ultimately resulting in enhanced performance, efficiency, and sustainability.

- Q: What are the different methods for improving the magnetic properties of special steel?

- Improving the magnetic properties of special steel can be achieved through various methods. One effective approach is heat treatment, which involves subjecting the steel to specific heating and cooling processes. This alters the atomic structure of the steel, enhancing its magnetic properties. For example, annealing the steel at high temperatures and slowly cooling it can create a fine-grained microstructure, resulting in improved magnetic performance. Another method is alloying, where certain elements like nickel, cobalt, or aluminum are added to the steel. Even small amounts of these alloying elements can significantly enhance the steel's magnetic characteristics, increasing its saturation magnetization and improving coercivity. Cold working, also known as cold deformation, is another technique that can improve the steel's magnetic properties. By subjecting the steel to mechanical stress at low temperatures, dislocations and defects are formed within its crystal structure, leading to improved magnetization, permeability, and reduced hysteresis losses. Grain orientation is yet another method to improve the magnetic properties of special steel. This involves aligning the grains of the steel in a specific direction through processes like hot rolling or magnetic annealing. This alignment results in anisotropic magnetic properties, meaning the steel will exhibit different magnetic characteristics depending on the direction of the applied magnetic field. Surface treatments can also be utilized to enhance the magnetic properties of special steel. Coatings such as electroplating, electroless plating, or chemical vapor deposition can modify the steel's surface, improving its magnetic performance. These treatments reduce eddy current losses, enhance corrosion resistance, and increase magnetic permeability. It is important to consider specific requirements and desired characteristics when choosing a method to improve the magnetic properties of special steel. Each method has its own advantages and limitations, and factors like cost, feasibility, and desired magnetic performance should be taken into account.

- Q: What are the thermal properties of special steel?

- Special steels have unique thermal properties that make them highly desirable in various applications. One of the key thermal properties of special steel is its high thermal conductivity. This means that it is able to efficiently transfer and dissipate heat. This property makes special steel ideal for use in heat exchangers, where it can effectively transfer heat between fluids. Additionally, special steel has a high melting point, which allows it to withstand high temperatures without deforming or losing its structural integrity. This makes it suitable for applications that involve exposure to extreme heat, such as in furnaces or aerospace engines. Furthermore, special steel exhibits excellent thermal expansion properties. It expands and contracts at a relatively consistent rate with changes in temperature, minimizing the risk of warping or cracking. This property is particularly important in applications where dimensional stability is crucial, such as in precision instruments or high-temperature machinery. Moreover, special steel can also possess good resistance to thermal fatigue. This means that it can withstand repeated heating and cooling cycles without developing cracks or weakening. This property is especially beneficial in applications that involve cyclic thermal loading, such as in automotive engine components or turbine blades. In summary, special steel possesses high thermal conductivity, a high melting point, excellent thermal expansion properties, and resistance to thermal fatigue. These thermal properties make it a preferred choice in a wide range of industries, including automotive, aerospace, energy, and manufacturing, where thermal performance and durability are crucial.

- Q: How does special steel resist wear and abrasion?

- Special steel resists wear and abrasion due to its unique composition and manufacturing process. It is typically made from alloys with high levels of carbon, chromium, and other elements that enhance its hardness and strength. The addition of these elements creates a microstructure within the steel that is highly resistant to wear and abrasion. Additionally, special steel can be heat-treated to further increase its hardness and toughness, making it more resilient against the forces that cause wear and abrasion. Overall, the combination of alloying elements and heat treatment gives special steel its exceptional ability to resist wear and abrasion in various applications.

- Q: What are the challenges in heat treating special steel?

- Some of the challenges in heat treating special steel include achieving uniform heating and cooling rates, controlling distortion and warping, managing the formation of unwanted phases or microstructures, maintaining precise temperature control, and ensuring consistent and repeatable results. Additionally, special steels may have specific alloying elements or compositions that require specialized heat treatment processes or equipment, further adding to the complexity and challenges in heat treating these materials.

- Q: How does special steel contribute to improving product safety?

- Special steel contributes to improving product safety in several ways. Firstly, special steel is known for its exceptional strength and durability, making it highly resistant to corrosion, wear, and impact. This robustness ensures that products made with special steel can withstand various external forces and environmental conditions, reducing the likelihood of structural failures or accidents. Additionally, certain types of special steel possess unique properties, such as heat resistance or high conductivity, which are crucial for applications in industries like aerospace and automotive, where safety is of utmost importance. Moreover, special steel undergoes rigorous testing and quality control processes to ensure its compliance with safety standards and regulations, guaranteeing the reliability and consistency of the final products. Overall, the utilization of special steel in manufacturing enhances product safety by providing superior strength, resilience, and adherence to safety guidelines.

- Q: How does special steel perform in terms of hardness?

- Special steel performs exceptionally well in terms of hardness. Due to its unique alloy composition and precise manufacturing process, it exhibits superior hardness compared to conventional steel. This enhanced hardness allows special steel to withstand high pressures, resist wear and tear, and provide excellent performance in demanding applications across various industries.

Send your message to us

Carbon Steel S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords