S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

1. 2080

1. cold work mould/die steel

2. High carbon high chromium type ledeburite

3. High hardness wear resistance

Product description

1. Cr12 steel is a widely used cold work die steel, a type of high carbon high chromium ledeburite . The steel has good hardenability and good abrasion resistance

2. Mainly used to with stand the impact load is smaller, and require high abrasion resistance Die and punch, cold-cut scissors, drill sets, gauges, drawing die, pressure die thread rolling board, drawing die thread rolling die.

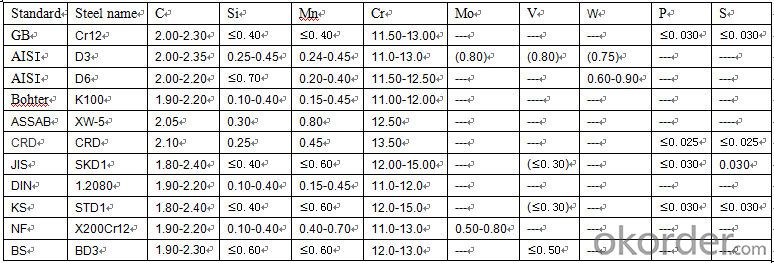

Chemical composition(for reference only)

Delivery of hardness and quenching hardness

Steel name | Delivery status | Quenched specimens | |||

Hardness HBW | Impressiondiameter (mm) | Quenching temperature/°C | Cooling medium | hardness ≥HRC | |

Cr12 | 269~217 | 3.7~4.1 | 950~1000 | oil | 60 |

Physical properties

Cr12 critical temperature

Critical point | Ac1 | Acm | Ar1 | Arcm | Ms |

temperature(approximation)/°C | 810 | 835 | 755 | 770 | 180 |

Cr12 Hot Working Technology

Item | Heating temperature/°C | start forging temperature/°C | final forging temperature/°C | type of cooling |

Steel ingot | 1140~1160 | 1100~1120 | 900~920 | Slow cooling |

Steel billet | 1120~1140 | 1080~1100 | 880~920 | Slow cooling |

Cr12 heat treatment

between the quenching temperature and the hardness of the relationship

quenching temperature/°C | 875 | 900 | 925 | 950 | 975 | 1000 | 1050 | 1100 |

Hardness HRC | 54.5 | 57 | 60 | 62.5 | 65 | 66 | 64 | 59.5 |

Delivery status: steel delivered in the annealed condition

We are professional manufacture of tool steel. We can provide various kinds of tool steel and mould steel. If you have any question regarding our products ,please feel free to let us know. We assure you will receive our best attention to your enquiry.

Products

- Q: What are the disadvantages of using steel round bars?

- There are a few disadvantages associated with using steel round bars. Firstly, steel round bars can be quite heavy, making them difficult to handle and transport. Secondly, steel round bars can corrode if not properly protected, which can lead to structural weakness and reduced lifespan. Additionally, steel round bars may not be suitable for certain applications that require lightweight or non-magnetic materials. Lastly, steel round bars can be more expensive compared to other materials, which may impact the overall project cost.

- Q: What are the chemical composition requirements for steel round bars?

- The chemical composition requirements for steel round bars vary depending on the specific grade or type of steel being used. However, in general, steel round bars are typically made from carbon steel, alloy steel, or stainless steel. Carbon steel round bars typically have a chemical composition consisting of iron and carbon, with trace amounts of other elements such as manganese, phosphorus, sulfur, and silicon. The carbon content in carbon steel round bars can range from 0.08% to 2.1%, depending on the desired strength and hardness. These bars are commonly used in construction, manufacturing, and general-purpose applications. Alloy steel round bars contain additional alloying elements such as chromium, nickel, molybdenum, vanadium, and manganese. These elements are added to enhance the mechanical properties of the steel, such as improved strength, hardness, and resistance to wear and corrosion. The specific chemical composition requirements for alloy steel round bars can vary significantly depending on the desired properties and the specific alloy being used. Stainless steel round bars are composed primarily of iron, chromium, and nickel, along with smaller amounts of other elements such as carbon, manganese, and molybdenum. The high chromium content in stainless steel provides excellent corrosion resistance, while the nickel content enhances its strength and ductility. The chemical composition requirements for stainless steel round bars are typically specified by international standards such as ASTM or EN, which outline the minimum and maximum allowable percentages of each element. In summary, the chemical composition requirements for steel round bars depend on the specific grade or type of steel being used, with carbon steel, alloy steel, and stainless steel being the most common types. The composition of these bars is carefully controlled to achieve the desired mechanical properties and performance characteristics for various applications.

- Q: What is the maximum weight capacity of a steel round bar?

- The maximum weight capacity of a steel round bar depends on its diameter, length, and the specific type of steel used.

- Q: Are steel round bars suitable for use in food processing equipment?

- Steel round bars are not suitable for use in food processing equipment. This is because food processing equipment necessitates materials that can resist corrosion, are easy to clean, and do not react with food substances. Although steel round bars are strong and durable, they have a tendency to rust and can potentially contaminate food with metallic particles. On the other hand, stainless steel is the ideal choice for food processing equipment due to its high resistance to corrosion, ease of cleaning, and non-reactive properties. It is crucial to prioritize the safety and hygiene of food processing equipment, which is why steel round bars should not be utilized in this context.

- Q: What are the different types of steel round bar coatings used in the oil and gas industry?

- There are several types of steel round bar coatings commonly used in the oil and gas industry. Some of these coatings include fusion bonded epoxy (FBE), three-layer polyethylene (3LPE), three-layer polypropylene (3LPP), and metallic zinc coatings. These coatings are applied to steel round bars to provide corrosion resistance, enhance durability, and protect against harsh environmental conditions in oil and gas applications.

- Q: What are the different types of steel round bar surface defects?

- There are several types of steel round bar surface defects, including pits, roll marks, scratches, cracks, scale, and decarburization.

- Q: Can steel round bars be used in electrical applications?

- Steel round bars are indeed applicable for electrical purposes. Due to its excellent conductivity, steel is well-suited for grounding systems and electrical connections. In the construction of electrical transmission towers, electrical enclosures, and electrical panels, steel round bars are frequently utilized. Furthermore, in electrical installations, steel round bars offer structural support, contributing to the system's overall stability and strength. Nevertheless, it is crucial to verify that the steel round bars conform to the required electrical safety standards and possess adequate insulation measures to avert any potential electrical risks.

- Q: What are the advantages of using weather-resistant steel round bars?

- There are several advantages to using weather-resistant steel round bars. Firstly, weather-resistant steel round bars are designed to withstand the effects of harsh weather conditions. They are specifically formulated to resist corrosion, rust, and other forms of degradation caused by exposure to rain, snow, humidity, and even saltwater environments. This makes them highly suitable for outdoor applications, such as construction projects, marine structures, and infrastructure in coastal areas. Secondly, the use of weather-resistant steel round bars eliminates the need for additional protective coatings or treatments. Unlike regular steel, which requires regular maintenance and painting to prevent rust and corrosion, weather-resistant steel round bars possess a natural protective layer that forms on the surface, known as patina. This patina acts as a barrier against further corrosion, reducing the overall maintenance requirements and extending the lifespan of the material. Thirdly, weather-resistant steel round bars offer exceptional strength and durability. They are manufactured using a special alloy composition, which enhances their mechanical properties and makes them highly resistant to impact, bending, and fatigue. This makes them ideal for structural applications where strength and reliability are crucial, such as in bridges, building frameworks, and heavy machinery. Additionally, weather-resistant steel round bars have aesthetic advantages. The unique patina that develops on the surface of these bars gives them a distinctive appearance, often described as an attractive and warm reddish-brown color. This natural weathered look can be desirable for architectural and design purposes, adding a visually appealing element to structures and outdoor installations. Lastly, the use of weather-resistant steel round bars contributes to sustainability and cost-effectiveness. Due to their long lifespan and low maintenance requirements, these bars offer a more sustainable solution compared to traditional steel, which often requires frequent painting and replacement. Furthermore, the initial investment in weather-resistant steel round bars may be higher than regular steel, but the long-term savings in maintenance and replacement costs make them a cost-effective choice in the long run. In conclusion, the advantages of using weather-resistant steel round bars include their ability to withstand harsh weather conditions, eliminate the need for additional protective coatings, provide exceptional strength and durability, offer aesthetic appeal, and contribute to sustainability and cost-effectiveness.

- Q: What is the red hardness of a steel round bar?

- The ability of a steel round bar to maintain its hardness and resistance to deformation at high temperatures is known as its red hardness. It indicates the steel's capacity to retain its strength and hardness when exposed to heat. Steels with higher carbon content typically demonstrate greater red hardness. This characteristic is crucial in situations where the steel is exposed to elevated temperatures, like in forging or heat-treating processes. Determining the red hardness of a steel round bar involves conducting different tests and measurements, including hardness testing at varying temperatures or assessing the steel's microstructure.

- Q: What is the maximum length of a steel round bar that can be produced?

- The maximum length of a steel round bar that can be produced depends on various factors such as the manufacturing process, equipment capabilities, and logistical constraints. However, in general, steel round bars can be produced in lengths ranging from a few feet to several hundred feet.

Send your message to us

S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords