CARBON STEEL PIPE FITTING TEE CNBM 2''-48''

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

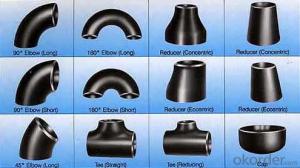

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: Are steel pipes suitable for underground oil pipelines?

- Yes, steel pipes are suitable for underground oil pipelines. Steel pipes are commonly used in underground oil pipelines due to their durability, strength, and resistance to corrosion, making them a reliable choice for transporting oil over long distances. Additionally, steel pipes can withstand high pressure and extreme temperatures, ensuring the safe and efficient transport of oil underground.

- Q: Can steel pipes be used for conveyor systems?

- Yes, steel pipes can be used for conveyor systems. Steel pipes are known for their strength, durability, and resistance to wear and tear, making them suitable for handling heavy loads and continuous operation in conveyor systems. Additionally, steel pipes can be easily welded, allowing for customization and flexibility in conveyor designs.

- Q: What is the difference between steel pipes and PVC pipes?

- The main difference between steel pipes and PVC pipes lies in their material composition. Steel pipes are made of a durable and strong metal alloy, while PVC pipes are made of a lightweight and flexible plastic called polyvinyl chloride. Steel pipes are typically used for heavy-duty applications that require high strength and resistance to extreme temperatures and pressure, such as in industrial settings or for transporting liquids or gases over long distances. On the other hand, PVC pipes are commonly used for residential and commercial plumbing systems due to their affordability, ease of installation, and resistance to corrosion. Additionally, PVC pipes are not suitable for high-pressure applications and have a lower heat tolerance compared to steel pipes.

- Q: How do steel pipes handle high-pressure applications?

- Steel pipes are able to handle high-pressure applications due to their inherent strength and durability. They have a high tensile strength and are resistant to deformation under extreme pressure. Additionally, the seamless construction of steel pipes ensures that there are no weak points or joints that can compromise their ability to handle high pressures.

- Q: What is the tensile strength of steel pipes?

- The grade and type of steel used can cause variation in the tensile strength of steel pipes. However, steel pipes generally possess a high tensile strength. Carbon steel pipes typically have a tensile strength range from 370 to 700 MPa, while alloy steel pipes can have a tensile strength range from 770 to 1200 MPa. These impressive tensile strengths enable steel pipes to withstand substantial pressure and stress, making them suitable for diverse applications in industries like construction, oil and gas, and automotive. It is important to recognize that factors like the manufacturing process, heat treatment, and the presence of defects or imperfections can also impact the tensile strength of steel pipes. Hence, it is recommended to consult the manufacturer's specifications or industry standards to determine the precise tensile strength of a specific steel pipe.

- Q: How are steel pipes insulated to prevent freezing?

- Steel pipes are typically insulated using materials such as foam or fiberglass insulation, which are wrapped around the pipes. This insulation helps to prevent freezing by providing a barrier between the cold temperatures outside and the pipes, thus maintaining the necessary heat inside the pipes to prevent freezing.

- Q: Can steel pipes be used for transportation of hazardous materials?

- The transportation of hazardous materials can indeed utilize steel pipes. Steel is renowned for its robustness, longevity, and resistance to rust, which renders it suitable for the management and conveyance of various perilous substances. This encompasses combustible liquids, noxious chemicals, and other hazardous materials. Steel pipes, employed for the transportation of hazardous materials, are frequently custom-designed and fabricated to comply with strict safety regulations and industry standards. They are typically forged from top-notch steel alloys and subjected to stringent tests to guarantee their integrity and resistance to leaks or ruptures. Additionally, steel pipes can be manufactured with supplementary protective coatings or linings to furnish an extra layer of security and avert any potential reactions between the hazardous substance and the steel. These coatings can also aid in reducing the risk of corrosion and prolonging the lifespan of the pipes. In summary, steel pipes have an established record in the transportation of hazardous materials due to their inherent strength, durability, and ability to withstand the challenging conditions frequently encountered during transportation. Nonetheless, it is imperative to adhere to proper protocols for handling, storage, and transportation to ensure the safety of both the transported materials and the individuals involved in the process.

- Q: How are steel pipes used in fire protection systems?

- Steel pipes are an integral part of fire protection systems, primarily used for the distribution of water or other fire suppressants in buildings. These pipes are known for their strength, durability, and resistance to high temperatures, making them ideal for withstanding the intense conditions of a fire. In fire protection systems, steel pipes are commonly used to create a network of pipes that deliver water to sprinkler heads or fire hydrants throughout a building. This network ensures that water is readily available to suppress or extinguish a fire in case of an emergency. One of the key advantages of steel pipes in fire protection systems is their ability to withstand the high pressure and flow rates required for effective fire suppression. Steel pipes can handle the forceful water flow needed to quickly and efficiently distribute water to the affected areas, helping to control and extinguish the fire as soon as possible. Additionally, steel pipes are resistant to corrosion, which is essential for maintaining the integrity of the fire protection system over time. Corrosion can weaken pipes, leading to leaks or even complete failure, which can be catastrophic in a fire situation. Steel pipes, however, have a longer lifespan and require less maintenance compared to other pipe materials, ensuring the system remains reliable and functional for years to come. Furthermore, steel pipes are often used in fire protection systems due to their fire resistance properties. Steel is inherently fire-resistant, meaning it can withstand high temperatures without deforming or losing its structural integrity. This is crucial in fire protection systems as it allows the pipes to remain intact and continue delivering water even in the midst of a fire, ensuring the safety of occupants and minimizing damage to the building. In summary, steel pipes play a vital role in fire protection systems by ensuring a reliable and efficient distribution of water or fire suppressants. Their strength, durability, resistance to high temperatures, and corrosion resistance make them an ideal choice for effectively combating fires and safeguarding lives and property.

- Q: How do you prevent corrosion in steel pipes?

- One effective way to prevent corrosion in steel pipes is by applying a protective coating, such as paint or epoxy, to the surface of the pipes. This barrier creates a physical barrier between the pipe and the surrounding environment, preventing moisture and corrosive agents from coming into direct contact with the steel. Additionally, regular inspection and maintenance of the pipes, including cleaning and repairing any damaged coating, can help identify and address potential issues before they lead to corrosion.

- Q: What are the different types of steel pipe supports for offshore platforms?

- There are several types of steel pipe supports used for offshore platforms, including clamps, brackets, hangers, and saddles. These supports are designed to secure and stabilize the pipes, ensuring their durability and integrity in the harsh offshore environment.

Send your message to us

CARBON STEEL PIPE FITTING TEE CNBM 2''-48''

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords