2''-48'' INCH CARBON STEEL PIPE FITTING TEE CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

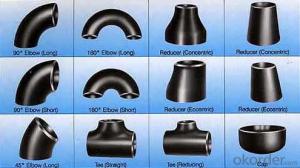

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: How are steel pipes threaded?

- Steel pipes are typically threaded using a threading machine or a hand-held die. The process involves cutting grooves on the outer surface of the pipe to create a spiral pattern, allowing the pipe to be easily connected to fittings or other pipes.

- Q: What are the advantages of using steel pipes in construction projects?

- There are several advantages of using steel pipes in construction projects. Firstly, steel pipes are incredibly strong and durable, making them ideal for carrying heavy loads and withstanding harsh environmental conditions. Secondly, steel pipes have a high resistance to corrosion, which ensures a longer lifespan and reduces maintenance costs. Additionally, steel pipes are lightweight, making them easier to transport and install. Lastly, steel pipes are versatile and can be used for various applications such as water supply, sewage systems, gas pipelines, and structural support.

- Q: What are the safety precautions while working with steel pipes?

- Some safety precautions while working with steel pipes include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, using proper lifting techniques to prevent back injuries, ensuring the work area is well-lit and free of obstacles, and using the correct tools and equipment for the job. Additionally, it is important to follow proper safety procedures when handling and storing steel pipes to minimize the risk of accidents or injuries.

- Q: How are steel pipes used in the manufacturing of appliances?

- Steel pipes are commonly used in the manufacturing of appliances as they are strong, durable, and resistant to corrosion. These pipes are used for various purposes such as supply and distribution of water, gas, and other fluids, as well as for structural support and framework in appliances. They are often used for creating the internal plumbing systems, ventilation ducts, and electrical conduits in appliances, ensuring efficient functioning and reliability.

- Q: What is the maximum temperature and pressure that steel pipes can withstand?

- The maximum temperature and pressure that steel pipes can handle differ based on the specific grade and type of steel utilized. Nevertheless, steel pipes generally have the ability to withstand high temperatures and pressures due to their robust and long-lasting nature. In applications where high temperatures are involved, like in steam or heat transfer systems, steel pipes can typically endure temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit) or even higher. It is important to note that the exact temperature limit may fluctuate depending on the steel's alloy composition and heat treatment. In terms of pressure, steel pipes are renowned for their exceptional strength and ability to resist internal and external pressure. The maximum pressure that steel pipes can handle will depend on factors such as pipe diameter, wall thickness, and material strength. In industrial applications, steel pipes can handle pressures ranging from a few hundred psi (pounds per square inch) to several thousand psi. To ensure the safe operation of steel pipes under high temperatures and pressures, it is vital to adhere to industry standards and guidelines, as well as conduct regular inspections and maintenance. Seeking advice from engineers and professionals experienced in steel pipe systems can provide more specific information regarding the maximum temperature and pressure limits for a particular steel pipe application.

- Q: How are steel pipes used in the electronics industry?

- Steel pipes are commonly used in the electronics industry for the transportation of various gases and liquids, such as coolant and process fluids, within electronic systems. They are also utilized for the construction of supporting structures and frameworks in electronic equipment and facilities.

- Q: What is the hardness of steel pipes?

- The specific grade and manufacturing process can cause the hardness of steel pipes to vary. Generally, alloys are used to make steel pipes, which offer a combination of strength and toughness. To determine the hardness of steel pipes, different methods like Rockwell or Brinell hardness tests can be carried out. These tests gauge the steel's resistance to indentation or penetration using a standardized indenter. The hardness of steel pipes is usually represented as a numerical value on a scale, like the Rockwell hardness scale (e.g., HRC or HRB) or the Brinell hardness scale (e.g., HB). The hardness of steel pipes is significant as it indicates their capacity to endure physical stresses, such as pressure, impact, or wear, in various applications such as construction, oil and gas transportation, and manufacturing.

- Q: Are steel pipes suitable for use in food processing industries?

- Yes, steel pipes are suitable for use in food processing industries. Steel pipes are known for their durability, strength, and resistance to corrosion, making them ideal for handling food products. They are also easy to clean and maintain, ensuring proper hygiene standards in the food processing industry. Additionally, steel pipes are capable of withstanding high temperatures and pressures, making them suitable for various food processing applications such as transporting liquids, gases, and solids.

- Q: Can steel pipes be used for offshore oil and gas platforms?

- Yes, steel pipes can be used for offshore oil and gas platforms. Steel pipes are commonly used in offshore oil and gas platforms due to their durability, strength, and resistance to harsh marine environments. These pipes are typically made of high-grade steel alloys that can withstand the extreme pressures and temperatures associated with offshore drilling and production activities. Furthermore, steel pipes are versatile and can be easily welded, allowing for the construction of complex pipeline networks on offshore platforms. Additionally, steel pipes can be coated with protective coatings such as epoxy or anti-corrosion coatings to enhance their resistance to corrosion and extend their lifespan in the offshore environment. Overall, steel pipes are a reliable and widely used choice for transporting oil and gas on offshore platforms.

- Q: How are steel pipes used in the chemical processing industry?

- Steel pipes are commonly used in the chemical processing industry for various purposes such as transporting chemicals, gases, and liquids, as well as for structural support and containment. They are highly durable, corrosion-resistant, and can withstand high temperatures and pressures, making them ideal for handling and conveying hazardous substances safely.

Send your message to us

2''-48'' INCH CARBON STEEL PIPE FITTING TEE CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords