All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

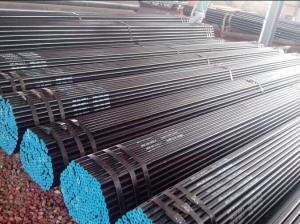

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for aerospace testing facilities?

Yes, welded steel pipes can be used for aerospace testing facilities. Welded steel pipes are known for their strength, durability, and resistance to high pressure and temperature, making them suitable for various industrial applications, including aerospace testing facilities. These pipes can effectively handle the transportation of different fluids, gases, or liquids required for testing purposes. Additionally, they can be customized to meet specific requirements, ensuring the safety and efficiency of aerospace testing operations.

Can welded steel pipe be used for steam applications?

Yes, welded steel pipe can be used for steam applications. Welded steel pipes are commonly used for steam transportation due to their high strength, durability, and resistance to high temperatures and pressure. However, it is important to ensure that the welded steel pipe meets the specific requirements and standards for steam applications to ensure safe and efficient operation.

What are the factors that determine the lifespan of a welded steel pipe?

The factors that determine the lifespan of a welded steel pipe include the quality of the steel used, the welding process and techniques employed, environmental conditions such as exposure to corrosive substances or extreme temperatures, maintenance and care, as well as the level of stress or pressure the pipe is subjected to during its operation.

How are welded steel pipes connected to each other or to other components?

Welded steel pipes are typically connected to each other or to other components using welding techniques such as butt welding, socket welding, or flanged connections. These methods involve melting the ends of the pipes or components together and allowing the molten metal to cool and solidify, creating a strong and permanent bond. The type of connection used depends on the specific application and requirements of the project.

What are the different methods used for pipe straightening in welded steel pipe manufacturing?

There are several methods used for pipe straightening in welded steel pipe manufacturing, including hydraulic straightening, mechanical straightening, and induction straightening. Hydraulic straightening involves applying pressure to the pipe using hydraulic cylinders to correct any bends or deformations. Mechanical straightening uses mechanical forces, such as rollers or bending machines, to straighten the pipe. Induction straightening uses the principle of electromagnetic induction to heat specific areas of the pipe, making it more malleable and allowing it to be straightened using external forces.

Wholesale Welded Steel Pipe from supplier in Mauritius

We offer a wide range of Welded Steel Pipe products to meet the needs of various industries in Mauritius. Our products are manufactured using high-quality materials and advanced manufacturing techniques to ensure durability and reliability.

Our team of experienced professionals is dedicated to providing excellent customer service and technical support. We understand the unique challenges faced by our customers and are committed to finding the best solutions for their specific requirements.

Whether you need Welded Steel Pipe for construction, infrastructure projects, or industrial applications, we have the expertise and resources to meet your needs. Our extensive network of suppliers allows us to offer competitive prices and ensure timely delivery.

At CNBM, we prioritize customer satisfaction and strive to exceed expectations in every aspect of our business. We have built a strong reputation for reliability, quality, and professionalism in the industry.

Contact us today to discuss your Welded Steel Pipe requirements in Mauritius. Our team will be happy to assist you with product selection, pricing, and any technical queries you may have.

Our team of experienced professionals is dedicated to providing excellent customer service and technical support. We understand the unique challenges faced by our customers and are committed to finding the best solutions for their specific requirements.

Whether you need Welded Steel Pipe for construction, infrastructure projects, or industrial applications, we have the expertise and resources to meet your needs. Our extensive network of suppliers allows us to offer competitive prices and ensure timely delivery.

At CNBM, we prioritize customer satisfaction and strive to exceed expectations in every aspect of our business. We have built a strong reputation for reliability, quality, and professionalism in the industry.

Contact us today to discuss your Welded Steel Pipe requirements in Mauritius. Our team will be happy to assist you with product selection, pricing, and any technical queries you may have.