Schedule 40/80 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

1. Commodity Name: Carbon Seamless Steel Pipe

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 2.5-80mm, SCH10~SCH40~XXL

Length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6. Application:

Carbon seamless steel pipes are applicable to gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

7. Payment Terms: L/C or T/T

8. Packing and Shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

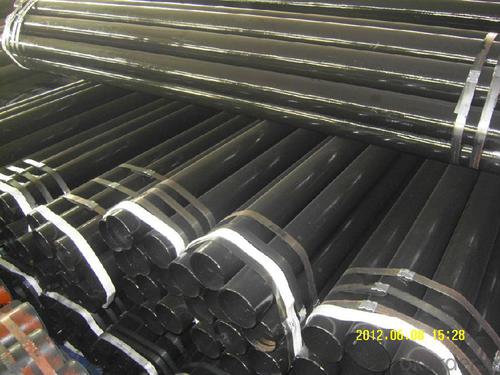

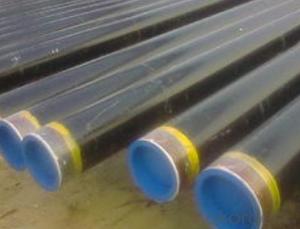

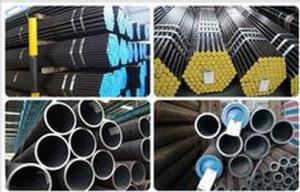

Seamless Steel Tubes Image

FAQ of Seamless Tube

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

- Q: What are the common applications of steel pipes in the water distribution system?

- The common applications of steel pipes in the water distribution system include carrying potable water from the water treatment plants to homes and businesses, transporting water for irrigation purposes, and facilitating the flow of water in industrial processes. Steel pipes are often preferred due to their durability, resistance to corrosion, and ability to handle high water pressure.

- Q: What is the difference between carbon steel pipes and stainless steel pipes?

- The main difference between carbon steel pipes and stainless steel pipes lies in their composition. Carbon steel pipes are primarily made of iron and carbon, while stainless steel pipes contain iron, carbon, and a minimum of 10.5% chromium. This chromium content in stainless steel pipes creates a protective layer of chromium oxide on the surface, making them highly resistant to corrosion. On the other hand, carbon steel pipes are more susceptible to corrosion and require additional coatings or treatments to prevent rusting. Additionally, stainless steel pipes offer better heat resistance and can withstand higher temperatures compared to carbon steel pipes.

- Q: Can steel pipes be used for underground sewerage systems?

- Yes, steel pipes can be used for underground sewerage systems. Steel pipes are commonly used in underground sewerage systems due to their durability, strength, and resistance to corrosion. They can withstand the weight of the soil and provide a long-lasting solution for transporting wastewater underground. Additionally, steel pipes are often preferred for larger diameter sewerage systems where high strength and structural integrity are crucial.

- Q: Can steel pipes be used for water distribution networks?

- Yes, steel pipes can be used for water distribution networks. Steel is a durable and strong material that can withstand high water pressure and provide a long-lasting solution for transporting water in distribution networks. However, it is important to properly coat the steel pipes with suitable materials to prevent corrosion and ensure the safety and quality of the water being distributed.

- Q: Are the welded and galvanized tubes the same weight?

- The difference is that because zinc has weight, even if the difference is very small, there are also differences,Galvanized pipe weight is basically the same about 1.06 of the welded tube, of course, you can artificially ignored.

- Q: How are steel pipes protected against UV radiation?

- Steel pipes are typically protected against UV radiation through the application of specialized coatings or paints that contain UV inhibitors. These coatings form a barrier between the steel surface and the sun's UV rays, preventing degradation, discoloration, and potential structural damage caused by prolonged exposure to UV radiation.

- Q: What are the different grades of steel used for pipes?

- The different grades of steel used for pipes include carbon steel, alloy steel, and stainless steel.

- Q: What is the difference between hot-dipped galvanized and electro-galvanized steel pipes?

- Both hot-dipped galvanized and electro-galvanized steel pipes undergo a galvanization process to protect them from corrosion. However, there are distinct differences between the two methods. Hot-dipped galvanized steel pipes are immersed in molten zinc, resulting in a thick zinc coating on the steel's surface. This creates a durable and long-lasting barrier against corrosion. The thickness of the zinc coating varies, but it is generally thicker than that of electro-galvanized steel pipes. In contrast, electro-galvanized steel pipes are coated with a thin layer of zinc through an electroplating process. This involves passing an electric current through the pipes while they are submerged in a zinc solution. The zinc particles are then deposited onto the steel's surface, creating a thin and uniform protective layer. One key difference is the thickness of the zinc coating. Hot-dipped galvanized steel pipes have a thicker and more robust coating, making them suitable for harsh environments or exposure to corrosive materials. Another distinction is the appearance of the pipes. Hot-dipped galvanized steel pipes typically have a dull grayish finish, while electro-galvanized steel pipes have a smoother and more polished look. In terms of cost, electro-galvanized steel pipes are generally more economical because the electroplating process requires less labor and zinc. Ultimately, the choice between hot-dipped galvanized and electro-galvanized steel pipes depends on the specific application and desired level of corrosion resistance. Hot-dipped galvanized steel pipes are typically used in demanding environments, while electro-galvanized steel pipes are suitable for less corrosive applications where cost-efficiency is important.

- Q: How are steel pipes used in the telecommunications infrastructure industry?

- Steel pipes are used in the telecommunications infrastructure industry to provide a strong and durable framework for the installation of fiber optic cables, conduits, and other communication equipment. They are used for underground cable routing, overhead cable support, and the construction of telecommunication towers, ensuring reliable and efficient communication networks.

- Q: What are the advantages of using steel pipes over other materials like PVC or copper?

- There are several advantages of using steel pipes over other materials like PVC or copper. Firstly, steel pipes are incredibly durable and can withstand high pressure and extreme temperatures, making them suitable for various industrial applications. They are also resistant to corrosion, ensuring a longer lifespan compared to PVC or copper pipes. Additionally, steel pipes have excellent structural strength, providing enhanced stability and safety. They are also environmentally friendly as they can be recycled, reducing their impact on the environment. Overall, steel pipes offer superior strength, longevity, and reliability, making them a preferred choice for many industries.

Send your message to us

Schedule 40/80 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords