carbon steel pipe ,carbon steel pipe price per ton,carbon steel seamless pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of carbon steel pipe:

Brand | seamless steel pipe |

Material | St35,St45,St52,E215,E235,E355,10,20, A106,A179,A192,A210,T11 |

T22,T12, AISI4130,SAE1010,SAE1020.etc | |

Standard | Meet or exceed ASTM,ASME,API,ANSI and DIN standards. |

ASTM A106/A179/A192/A210/A213/A519 etc. | |

DIN2391/DIN17175/EN10305 etc | |

GB8162/GB8163/GB3639 etc | |

Technique | Cold Drawn/Cold rolled |

Usage | 1. auto and motorcycle steel pipe |

2. Gas spring steel Tube | |

3. Boiler Pipe | |

4. Low and middle pressure fluid transportation pipeline | |

5. Hydraulic system steel tube | |

6. Electric industry |

Application | Cold drawn or cold rolled precision seamless steel tubes for hydraulic pressure and pneumatic services. |

For Auto use,machinery use,oil cylinder tube,motorcycle shock reducer use,auto shock reducer inner cylinder,gas spring use etc. | |

Seamless steel pipes for low and medium pressure boiler, high pressure boiler, ship-building,Liquid service, petroleum cracking, chemical fertilizer equipment,Drawing-oil-equipment and structure purposes. |

2、Main Features of the Seamless Pipe ASTM A106/53 ( carbon steel pipe):

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 ( carbon steel pipe) Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53 ( carbon steel pipe):

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

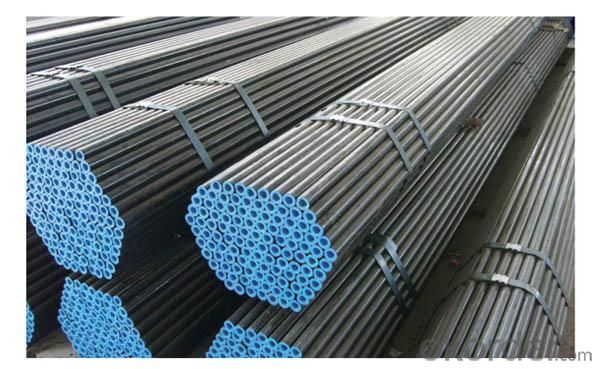

6、Seamless Pipe ASTM A106/53( carbon steel pipe) Images:

- Q: How are steel pipes used in the manufacturing industry?

- Steel pipes are used in the manufacturing industry for a wide range of applications, including the transportation of fluids and gases, structural support in buildings and infrastructure, and as a material for heat exchangers and boilers. They are also utilized in the production of various machinery and equipment, such as conveyors, cranes, and industrial piping systems. Overall, steel pipes play a crucial role in ensuring efficient and reliable operations across numerous manufacturing processes.

- Q: What is the impact of steel pipe size on flow rate and pressure?

- The size or diameter of a steel pipe has a significant impact on both flow rate and pressure. Firstly, the flow rate refers to the volume of fluid that can pass through the pipe per unit of time. A larger pipe diameter allows for a greater flow rate as there is more space for the fluid to move through. This is due to the fact that a larger cross-sectional area of the pipe offers less resistance to the flow of fluid. Therefore, increasing the size of the steel pipe will generally lead to an increase in flow rate. Secondly, the pressure within a pipe is influenced by its size. As the fluid flows through a pipe, it encounters resistance due to friction against the walls of the pipe. This resistance leads to a pressure drop along the length of the pipe. A smaller pipe diameter results in higher frictional losses, which leads to a greater pressure drop. On the other hand, a larger pipe diameter reduces frictional losses and therefore results in a lower pressure drop. Consequently, increasing the size of the steel pipe will generally lead to a decrease in pressure drop. It is important to note that while increasing the size of a steel pipe may generally result in a higher flow rate and lower pressure drop, there are other factors that can also affect these parameters. These include the fluid properties, the length and layout of the pipe, and any additional components such as valves or fittings. Therefore, it is crucial to consider all these factors and conduct proper calculations or simulations to accurately determine the impact of steel pipe size on flow rate and pressure in a specific system.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. They are durable, strong, and resistant to corrosion, making them ideal for handling the harsh environment and corrosive substances found in sewage treatment plants. Steel pipes also offer excellent flow characteristics and can withstand high pressure, making them reliable for transporting wastewater and sewage within the facility.

- Q: Can steel pipes be used for underground cable protection?

- Yes, steel pipes can be used for underground cable protection. Steel pipes provide excellent durability, strength, and resistance to external factors such as impact, corrosion, and fire. They can effectively shield and protect underground cables, ensuring their safety and longevity.

- Q: Seamless steel tube with the tube with what is the difference?

- Seamless pipe can withstand ultra-high pressure, of course, its wall thickness will increase, which needs to be designed according to pressure requirements. It is generally used in high-pressure oil pipes, boiler tubes and other high temperature and high pressure equipment. There are also seamless tubes for structural purposes, depending on the design requirements.

- Q: Can steel pipes be used for sewage disposal systems?

- Yes, steel pipes can be used for sewage disposal systems. Steel pipes are commonly used in sewage systems due to their durability, resistance to corrosion, and ability to withstand high pressure. They are suitable for carrying wastewater and sewage safely and efficiently.

- Q: Can steel pipes be used for chemical processing plants?

- Yes, steel pipes can be used for chemical processing plants. Steel pipes have excellent strength, durability, and resistance to corrosion, making them suitable for transporting various chemicals and fluids in a chemical processing plant. Additionally, steel pipes can withstand high temperatures and pressures, ensuring safe and efficient operations in such industrial settings.

- Q: Can steel pipes be used for conveying corrosive substances?

- Steel pipes can be used for conveying corrosive substances, but it is important to choose the right type of steel and consider additional protective measures. Stainless steel pipes, for example, are highly resistant to corrosion and can handle a wide range of corrosive substances. However, it is crucial to consider the specific corrosive properties of the substance being conveyed and the concentration levels. In some cases, additional protective coatings or linings may be necessary to prevent corrosion and ensure the longevity of the steel pipes. Regular maintenance and inspection are also essential to detect and address any signs of corrosion to prevent leaks or failures in the piping system. Overall, steel pipes can be used for conveying corrosive substances, but proper material selection, protective measures, and maintenance are vital to ensure safe and efficient operations.

- Q: What are the common sizes of steel pipe fittings?

- Depending on the particular application and industry regulations, the sizes of steel pipe fittings can vary. Nevertheless, there are numerous standard sizes that are commonly utilized in various industries. These sizes encompass a range from ¼ inch to 48 inches in diameter. Among the most frequently used sizes are ½ inch, ¾ inch, 1 inch, 1 ¼ inch, 1 ½ inch, 2 inch, 2 ½ inch, 3 inch, 4 inch, 6 inch, 8 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, 30 inch, 36 inch, 42 inch, and 48 inch. These sizes are often obtainable in different lengths to accommodate diverse installation requirements. To determine the appropriate size of steel pipe fittings for a specific project, it is crucial to refer to industry standards and specifications.

- Q: What is the difference between internal threading and external threading of steel pipes?

- The difference between internal threading and external threading of steel pipes lies in the location and method of threading. Internal threading refers to the process of creating threads on the inside surface of a steel pipe, allowing it to be connected to other components with external threads. On the other hand, external threading involves creating threads on the outside surface of a steel pipe, enabling it to be joined with components having internal threads. These two methods serve different purposes and are utilized depending on the specific requirements of the plumbing or assembly project.

Send your message to us

carbon steel pipe ,carbon steel pipe price per ton,carbon steel seamless pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords